Method for extracting dendrobium officinate kimura et migo polysaccharide by using ultrasonic method

A technology of Dendrobium officinale polysaccharide and ultrasonic method, which is applied in the fields of extracting Dendrobium officinale polysaccharides and components of Dendrobium officinale by acid-base method, can solve the problems of potential radiation risk, easily destructible polysaccharide components, large water demand, etc., and achieve environmental friendliness, Reduce the effect of subsequent steps and use less water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

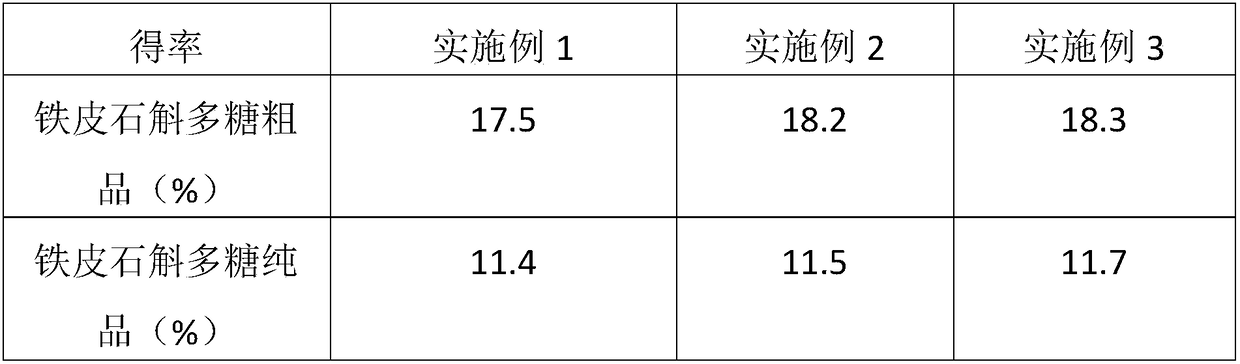

Examples

Embodiment 1

[0028] (1) Clean the raw material fresh Dendrobium candidum strips, dry them in the air, place them at 80° C. for 3 hours until the moisture content is <30%, and cut them into short strips of 1 cm;

[0029] (2) the short strips of Dendrobium candidum are submerged in water, and crushed to a slurry in a high-speed crusher to obtain the slurry of Dendrobium candidum;

[0030] (3) Put the Dendrobium officinale slurry into a closed container, place it in an ultrasonic extractor, and carry out ultrasonic water bath heating and extraction under the condition of ultrasonic power of 300W, ultrasonic frequency of 40Hz, and water bath heating temperature of 40°C, and the extraction time is 30min ;

[0031] (4) after extraction finishes, suction filtration, collect filtrate and filter residue;

[0032] (5) adding water to the filter residue until submerged, and repeating the ultrasonic extraction step;

[0033] (6) Mix the filtrate collected in steps (4) and (5), and add 0.1% activated...

Embodiment 2

[0039] (1) Clean the raw material fresh Dendrobium candidum strips, dry them in the air, place them in 85°C and dry them for 3 hours until the moisture content is <30%, and cut them into 2cm short strips;

[0040] (2) the short strips of Dendrobium candidum are submerged in water, and crushed to a slurry in a high-speed crusher to obtain the slurry of Dendrobium candidum;

[0041] (3) Put the Dendrobium officinale slurry into a closed container, place it in an ultrasonic extractor, and carry out ultrasonic water bath heating and extraction under the condition of ultrasonic power of 400W, ultrasonic frequency of 45Hz, and water bath heating temperature of 55°C, and the extraction time is 40min ;

[0042] (4) after extraction finishes, suction filtration, collect filtrate and filter residue;

[0043] (5) adding water to the filter residue until submerged, and repeating the ultrasonic extraction step;

[0044] (6) Mix the filtrate collected in steps (4) and (5), and add 0.1% ac...

Embodiment 3

[0050] (1) Clean the raw material fresh Dendrobium candidum strips, dry them in the air, place them at 95° C. for 4 hours until the water content is <30%, and cut them into short strips of 2 cm;

[0051] (2) the short strips of Dendrobium candidum are submerged in water, and crushed to a slurry in a high-speed crusher to obtain the slurry of Dendrobium candidum;

[0052] (3) Put the Dendrobium officinale slurry into a closed container, place it in an ultrasonic extractor, and carry out ultrasonic water bath heating and extraction under the condition of ultrasonic power of 500W, ultrasonic frequency of 50Hz, and water bath heating temperature of 65°C, and the extraction time is 50min ;

[0053] (4) after extraction finishes, suction filtration, collect filtrate and filter residue;

[0054] (5) adding water to the filter residue until submerged, and repeating the ultrasonic extraction step;

[0055] (6) Mix the filtrate collected in steps (4) and (5), and add 0.1% activated carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com