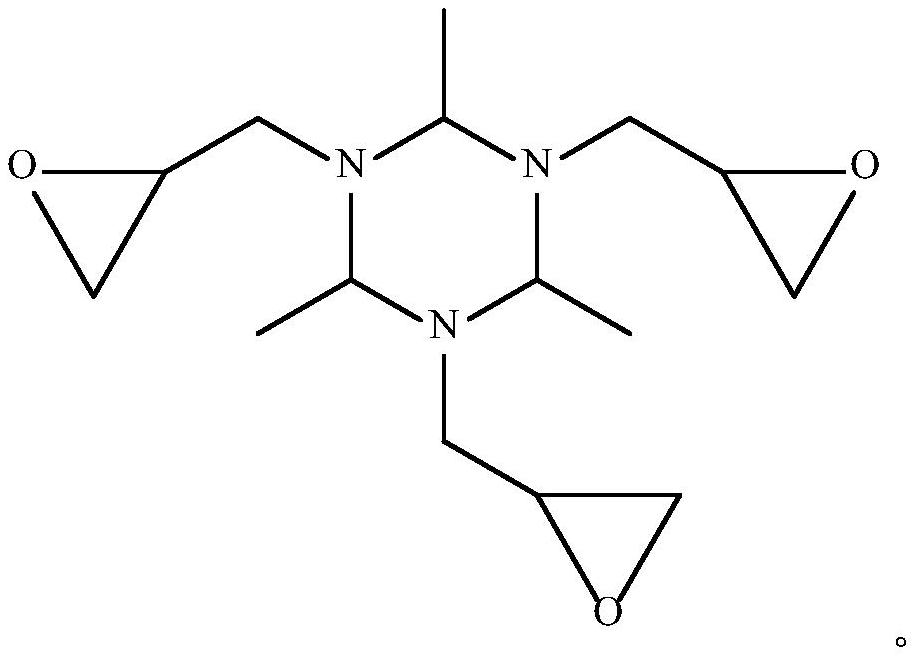

A kind of epoxy resin prepolymer containing hexahydrotriazine structure and preparation method thereof

A technology of epoxy resin and hexahydrotriazine, which is applied in the field of epoxy resin prepolymer containing hexahydrotriazine structure and its preparation, can solve the problems of difficult recycling of composite materials, inability to melt and plasticize, waste of resources, etc. To achieve the effect of controllable and adjustable reaction process, realization of recovery and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

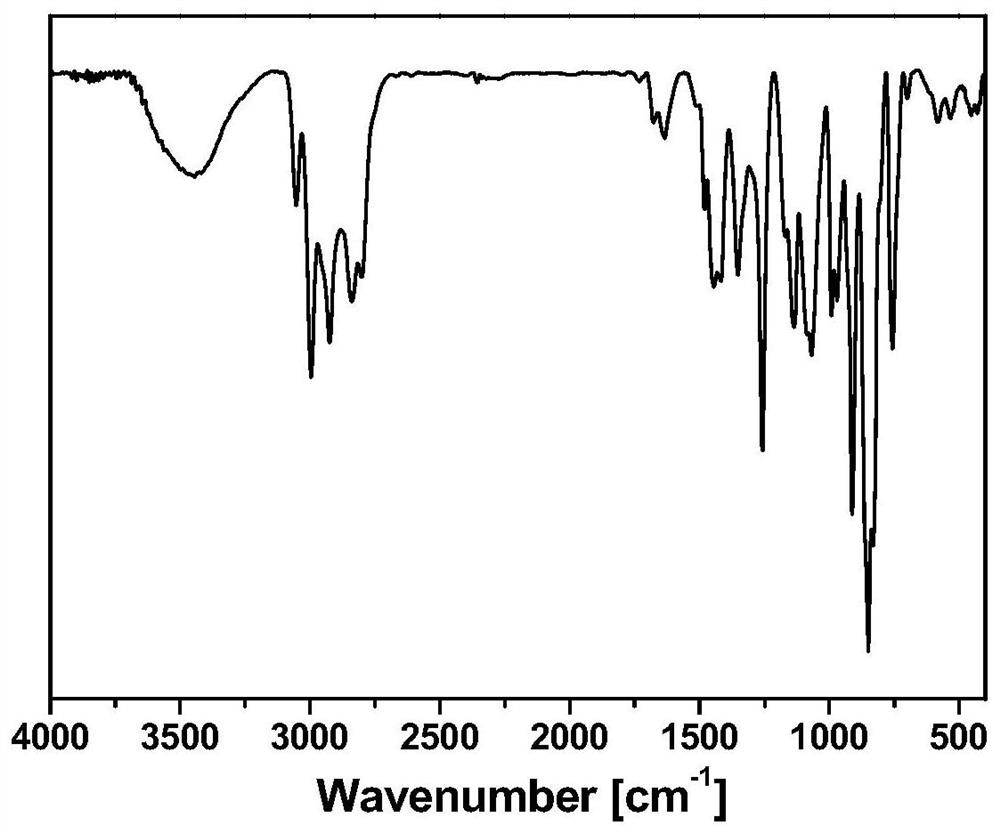

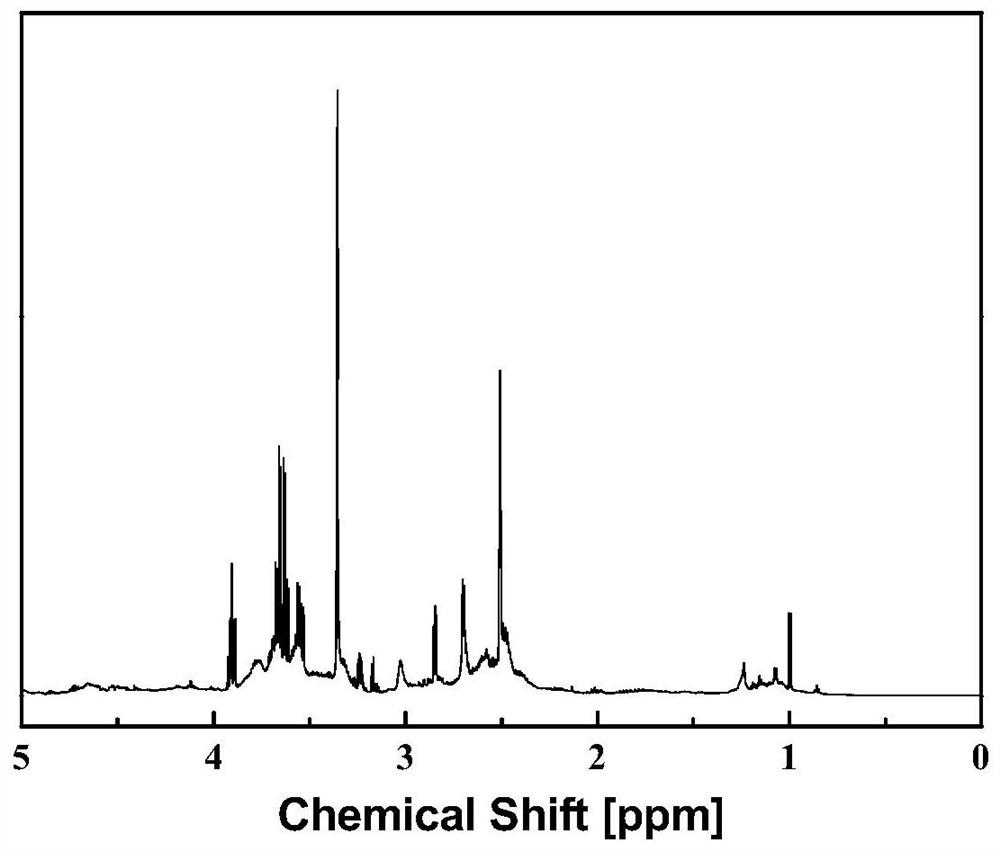

Method used

Image

Examples

Embodiment 1

[0022] Add 50g of acetaldehyde ammonia trimer and 320g of epichlorohydrin into a 1L three-necked glass flask with a reflux device, then fill the flask with nitrogen, put the three-necked flask into a constant temperature magnetic water bath, and slowly heat up to 90 ℃, continue the reaction for 1 hour after the acetaldehyde ammonia trimer is completely dissolved; after the reaction, cool down to 55 ℃, add 105 g of 50% sodium hydroxide aqueous solution evenly into the three-necked flask within 1 hour, and then continue the reaction for 0.5 hour After completing the ring closure reaction, it was cooled to room temperature. Remove the insoluble matter by filtration, then add 200ml of distilled water to the filtrate, shake well and stand still, then take the lower layer solution. Continuously wash 3 times with distilled water, remove and reclaim unreacted epichlorohydrin at last by rotary evaporation, obtain epoxy resin prepolymer 110g of the present invention, productive rate 95....

Embodiment 2

[0025] Add 50g of acetaldehyde ammonia trimer and 215g of epichlorohydrin into a 1L three-necked glass flask with a reflux device, then fill the flask with nitrogen, put the three-necked flask into a constant temperature magnetic water bath, and slowly heat up to 80 ℃, continue the reaction for 2 hours after the acetaldehyde ammonia trimer is completely dissolved; after the reaction, cool down to 45 ℃, add 130g of 40% sodium hydroxide aqueous solution evenly into the three-necked flask within 1.5 hours, and then continue the reaction for 1 hour After completing the ring closure reaction, it was cooled to room temperature. Remove the insoluble matter by filtration, then add 200ml of distilled water to the filtrate, shake well and stand still, then take the lower layer solution. Continuously wash 3 times with distilled water, remove and reclaim unreacted epichlorohydrin at last by rotary evaporation, obtain epoxy resin prepolymer 101.5g of the present invention, productive rate ...

Embodiment 3

[0027] Add 50g of acetaldehyde ammonia trimer and 120g of epichlorohydrin into a 1L three-necked glass flask with a reflux device, then fill the flask with nitrogen, put the three-necked flask into a constant temperature magnetic water bath, and slowly raise the temperature to 100 ℃, continue the reaction for 0.5h after the acetaldehyde ammonia trimer is completely dissolved; after the reaction, cool down to 50°C, add 85g of 60% sodium hydroxide aqueous solution evenly to the three-necked flask within 1h, and continue the reaction for 1h after the dripping is completed After completing the ring closure reaction, it was cooled to room temperature. Remove the insoluble matter by filtration, then add 200ml of distilled water to the filtrate, shake well and stand still, then take the lower layer solution. Continuously wash 3 times with distilled water, remove and reclaim unreacted epichlorohydrin at last by rotary evaporation, obtain epoxy resin prepolymer 102.8g of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com