Concrete prepared from artificial sand and stone powder

A concrete and artificial sand technology, applied in the field of concrete, can solve the problems of concrete work performance and compressive strength, etc., achieve good environmental and economic benefits, reduce costs, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

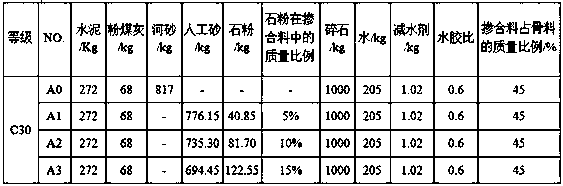

[0029] Prepare 4 groups of concrete according to the following raw materials and dosage. The raw materials are: 272kg of cement, 68kg of fly ash, 1000kg of crushed stone, 205kg of water, 1.02kg of water reducing agent, of which the amount of river sand or admixture is 817kg, When artificial sand and stone powder are used, the mass ratio of stone powder in the admixture is 5%, 10%, and 15%. The admixture composed of artificial sand and stone powder is fine aggregate, the coarse aggregate is crushed stone, and the mass ratio of admixture to aggregate (the sum of fine aggregate and coarse aggregate) is 45%.

[0030] The test mix ratio of this example is mainly designed for building concrete prefabricated parts, and the strength of concrete used for prefabricated building components is generally lower than C50. Therefore, what this embodiment prepares is the concrete of C30 mark. The specific raw materials used in the 4 groups of concrete are shown in Table 2.

[0031] Table 2 C...

Embodiment 2

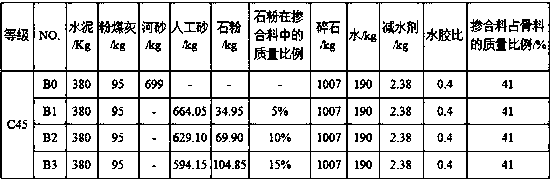

[0039] Prepare 4 groups of C45 concrete according to the following raw materials and dosage. Raw materials: 380kg of cement, 95 kg of fly ash, 1007kg of gravel, 190kg of water, 2.38kg of water reducing agent, of which the amount of river sand or admixture is 699kg , when artificial sand and stone powder are used, the mass ratio of stone powder in the admixture is 5%, 10%, and 15%.

[0040] The specific raw materials used in the 4 groups of concrete are shown in Table 4.

[0041] Table 4 C45 Concrete Mix Design

[0042]

[0043] The working performance and compressive strength of the four groups of concrete prepared above were tested, and the results are shown in Table 5.

[0044] Table 5 concrete working performance and compressive strength

[0045]

[0046] From the above Table 4 and Table 5, it can be seen that from the perspective of 3d and 7d compressive strength, the compressive strength of B1~B3 group concrete is generally slightly higher than that of B0 group, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com