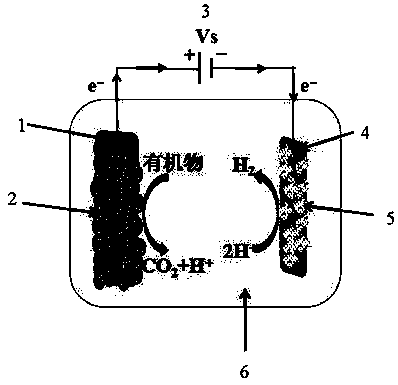

Preparation method and application of MoS2/transition metal/graphene composite hydrogen dissociation electrode in microbial electrolytic tank

A microbial electrolysis cell and graphene composite technology, which is applied in the fields of chemical power sources and new energy materials, can solve the problems of poor electrical conductivity, slow reaction kinetics, limited hydrogen evolution reaction speed, etc., and achieves a single product, simple preparation process, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 60 mg of graphene oxide and place it in a beaker, add 60 mL of deionized water, and then sonicate for 2 hours to obtain a graphene oxide aqueous solution.

[0043] (2) Weigh 66 mg of ammonium tetrathiomolybdate and add it to the solution obtained in (1), and sonicate for 10 minutes to obtain a uniform solution. Then add 80mgCuCl 2 2H 2 O Ultrasonic 10min. Finally, 2 mL of hydrazine hydrate was added and stirred evenly.

[0044] (3) Transfer the solution obtained in (2) to a 100mL autoclave, and react at 180°C for 12h. Finally, the reactor was cooled to room temperature, and the black precipitate in the reactor was collected, rinsed several times with deionized water and absolute ethanol, and then dried under vacuum at 60°C.

[0045] (4) Weigh 8 mg of MoS prepared in step (3) 2 / transition metal / graphene composite catalyst, placed in absolute ethanol and sonicated for 0.5 h to make a suspension. Draw up the suspension with a pipette gun, and evenly drop it ...

Embodiment 2

[0051] (1) Weigh 60 mg of graphene oxide and place it in a beaker, add 60 mL of deionized water, and then sonicate for 2 hours to obtain a graphene oxide aqueous solution.

[0052] (2) Weigh 132 mg of ammonium tetrathiomolybdate and add it to the solution obtained in (2), and sonicate for 10 minutes to obtain a uniform solution. Then add 50mgCuCl 2 2H 2 O Ultrasonic 10min. Finally, 1 mL of hydrazine hydrate was added and stirred evenly.

[0053] (3) Transfer the solution obtained in (2) to a 100mL autoclave, and react at 190°C for 11h. Finally, the reactor was cooled to room temperature, and the black precipitate in the reactor was collected, rinsed several times with deionized water and absolute ethanol, and then dried under vacuum at 60°C.

[0054] (4) Weigh 16 mg of MoS prepared in step (3) 2 / transition metal / graphene composite catalyst, placed in absolute ethanol and sonicated for 0.5 h to make a suspension. Draw up the suspension with a pipette gun, and evenly drop...

Embodiment 3

[0058] (1) Weigh 40 mg of graphene oxide and place it in a beaker, add 50 mL of deionized water, and then sonicate for 2 hours to obtain a graphene oxide aqueous solution.

[0059] (2) Weigh 44 mg of ammonium tetrathiomolybdate and add it to the solution obtained in (2), and sonicate for 10 minutes to obtain a uniform solution. Then add 40mgZn(NO 3 ) 2 ·6H 2 O Ultrasonic 10min. Finally, 1 mL of hydrazine hydrate was added and stirred evenly.

[0060] (3) Transfer the solution obtained in (2) to a 100mL autoclave, and react at 200°C for 10h. Finally, the reactor was cooled to room temperature, and the black precipitate in the reactor was collected, rinsed several times with deionized water and absolute ethanol, and then dried under vacuum at 60°C.

[0061] (4) Weigh 12 mg of MoS prepared in step (3) 2 / transition metal / graphene composite catalyst, placed in absolute ethanol and sonicated for 0.5 h to make a suspension. Draw up the suspension with a pipette gun, and evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com