Technology method and device of pneumatic separation and magnetic separation for dry method ore grinding of iron ores

A dry grinding technology for ore and iron ore, which is applied in the direction of drying gas arrangement, chemical instruments and methods, drying, etc., can solve the problems of large water resource consumption, achieve low wind and power consumption, and reduce over-grinding Phenomenon, the effect of less overgrinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

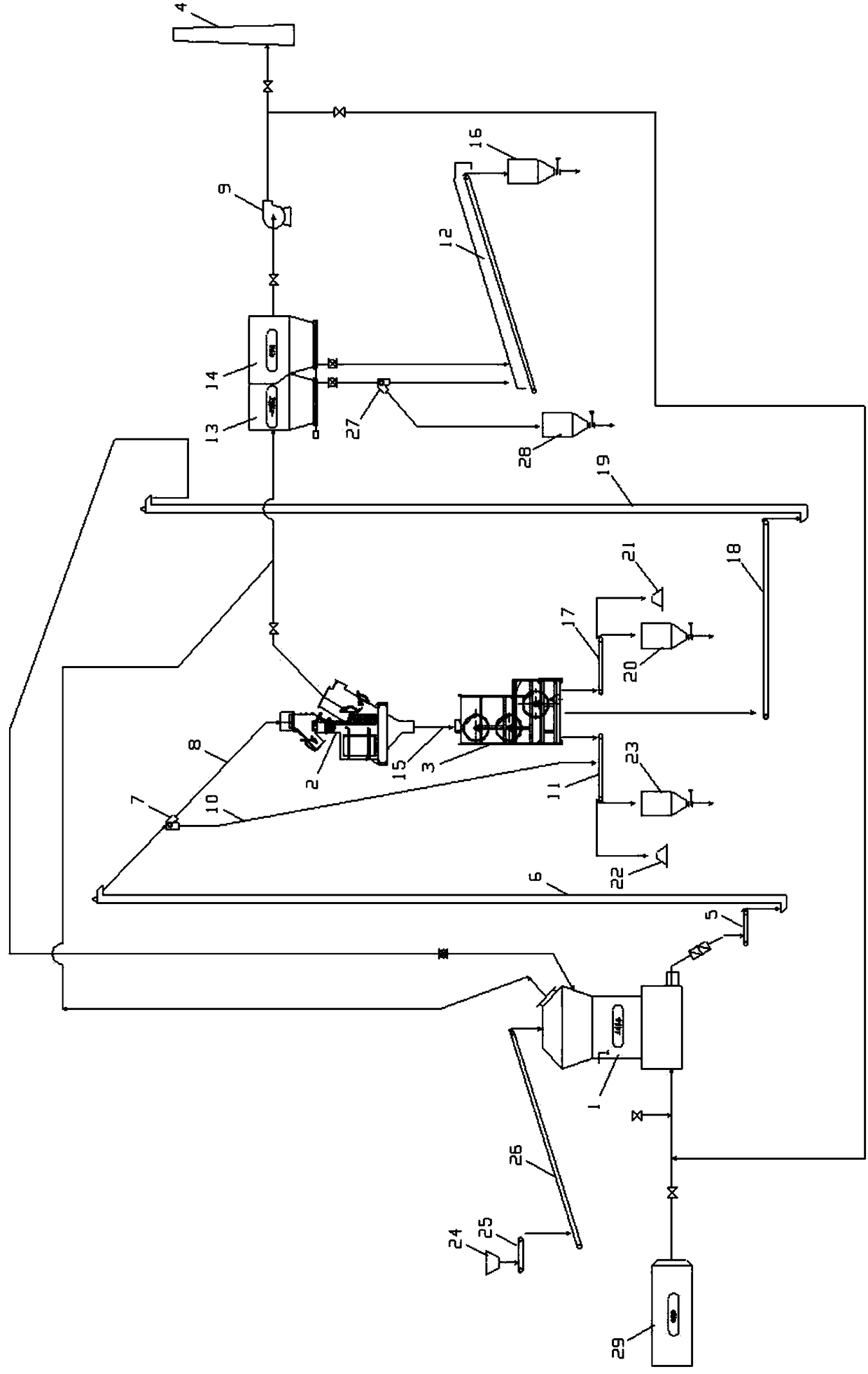

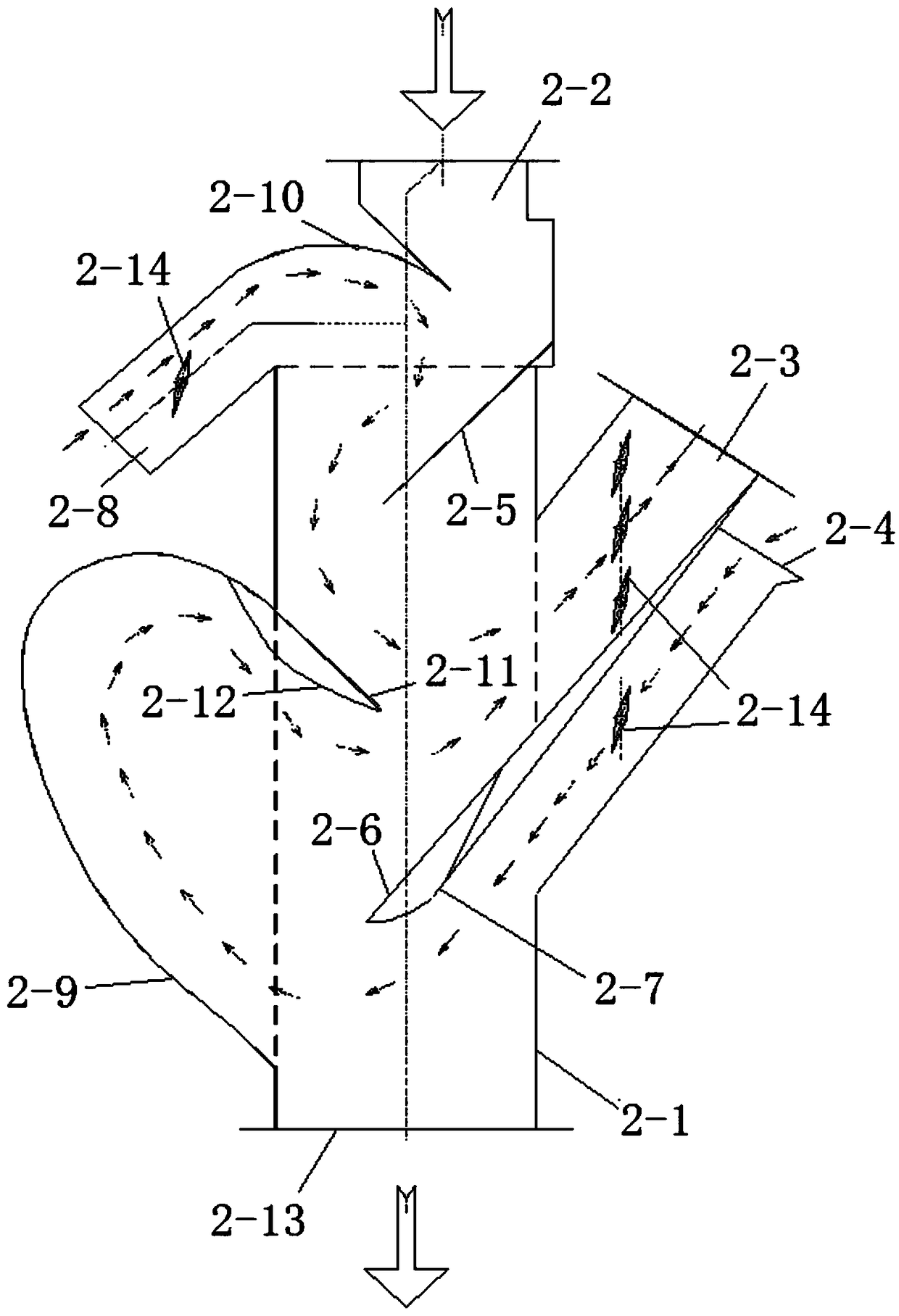

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

[0031] A kind of process method of the dry grinding wind separation magnetic separation that is used for iron ore of the present invention, comprises the following steps:

[0032] (a) Dry grinding: the crushed iron ore is ground into a mixture of ore particles and ore powder through a dry vertical mill;

[0033] (b) Wind separation and classification: the ore powder and ore particles are separated by a multi-stage lifting air separator, and then the separated ore powder is collected by a powder collecting device;

[0034] (c) Dry multi-stage magnetic separation: the ore particles are subjected to multi-stage magnetic separation through a multi-stage magnetic roller concentrator, and are separated into high-grade concentrates, general-grade medium ore and low-grade tailings, respectively. The ore and tailings are collected, and the middlings are returned to the dry ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com