Bioactive glass composite film as well as preparation method and application thereof

A technology of bioactive glass and composite film, applied in the field of oral biomedical materials, to achieve the effect of promoting remineralization, promoting recovery and avoiding drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

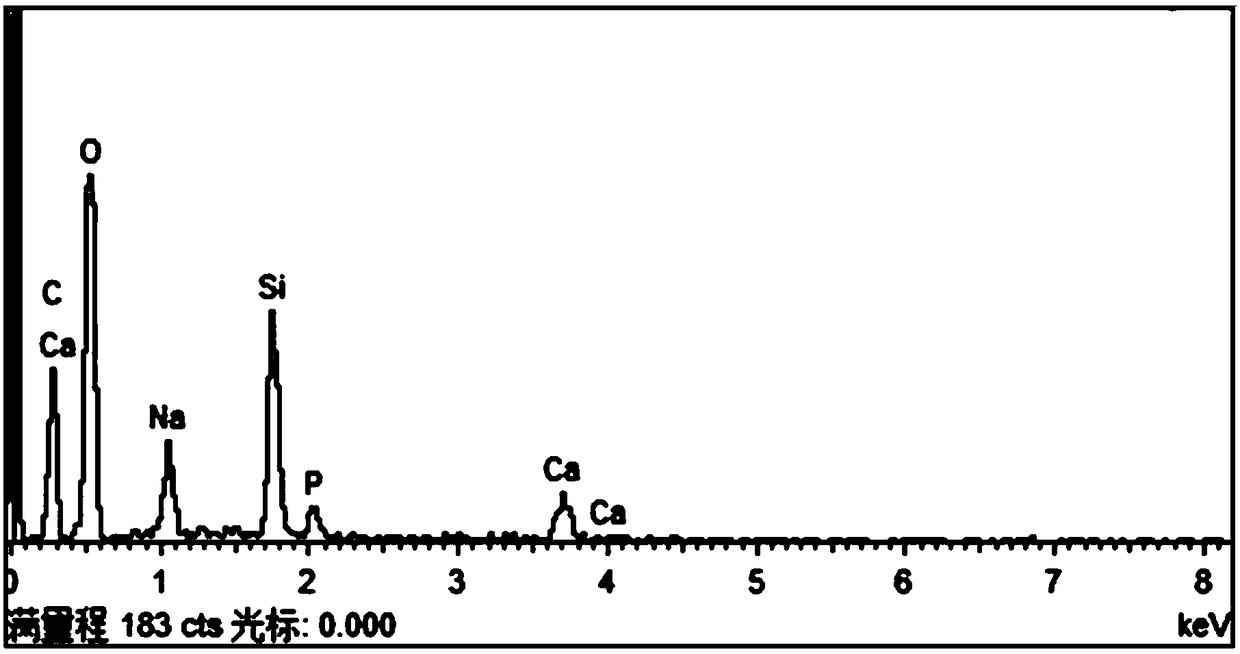

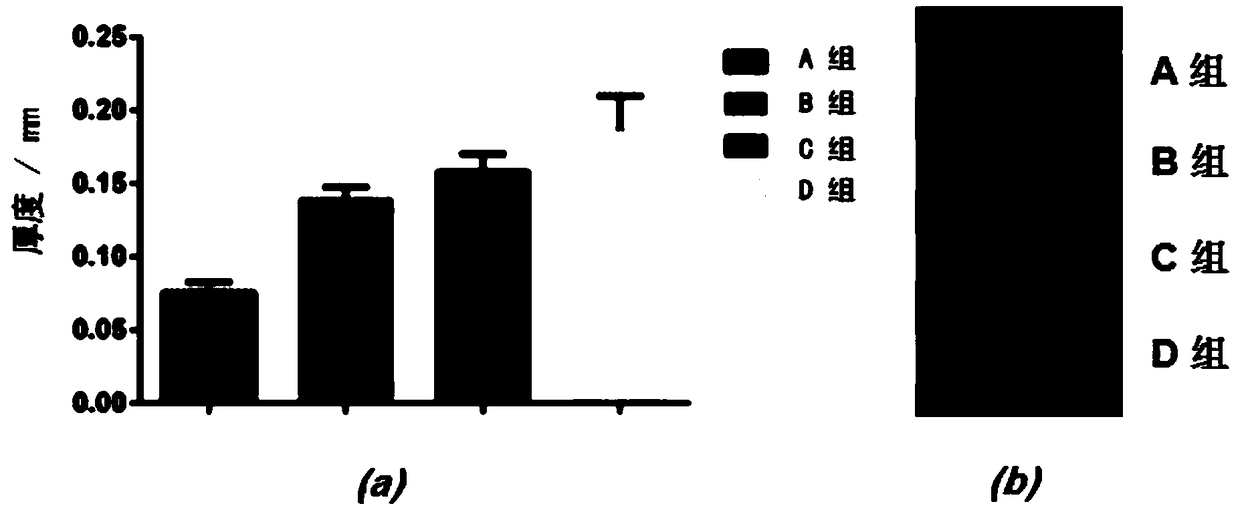

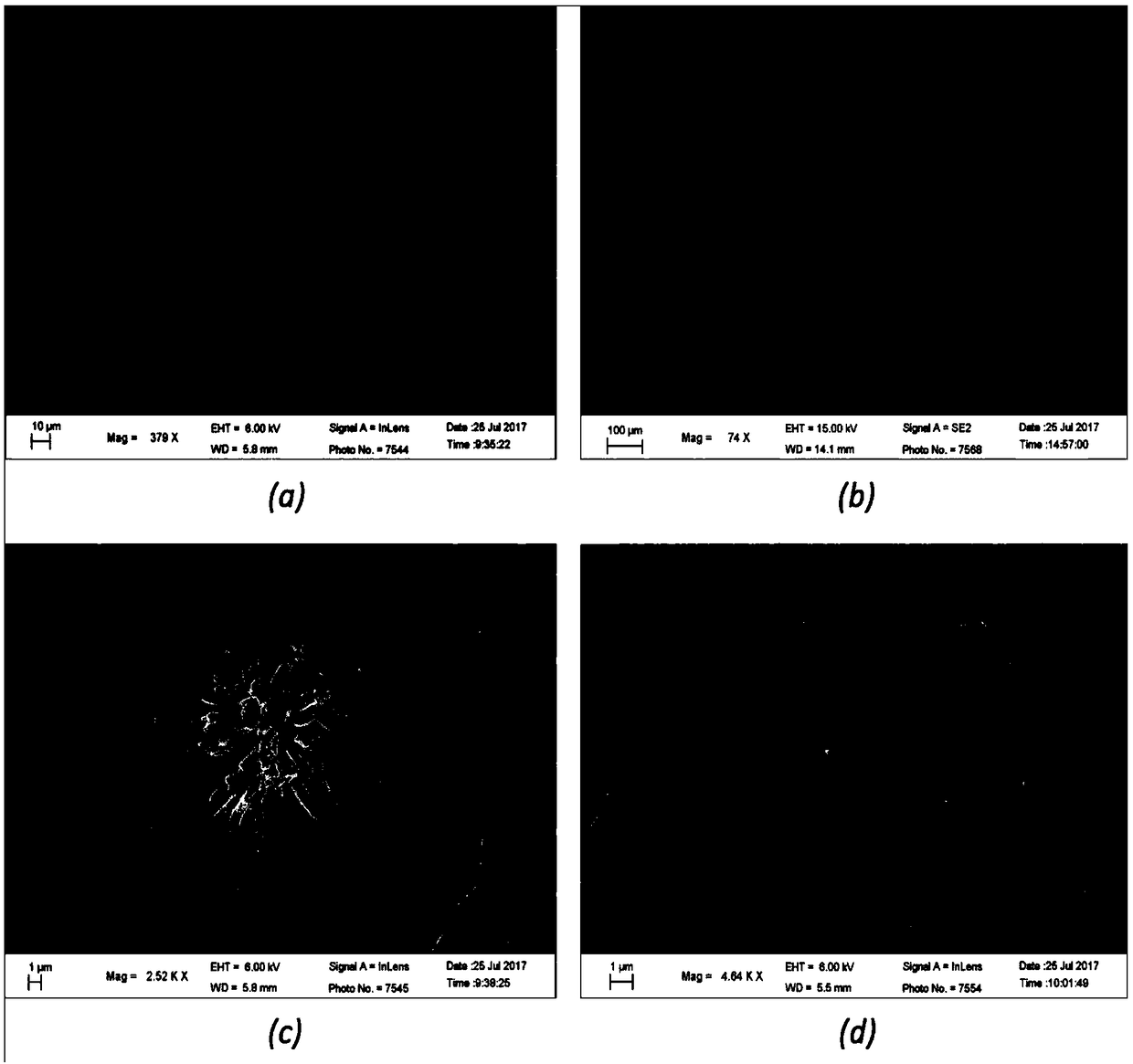

Method used

Image

Examples

preparation example Construction

[0055] In addition, the present invention also provides a method for preparing the bioactive glass composite film, which specifically includes the following steps:

[0056] 1) Polylactic acid-glycolic acid terminal activation

[0057]

[0058] Dissolve polylactic acid-glycolic acid in organic solvent A (mixture of one or more of methanol, ethanol, ether, acetonitrile, chloroform, methylene chloride, dimethyl sulfoxide), add DCC (N, N-di Cyclohexylcarbodiimide) and N-hydroxyl-succinimide, add catalytic amount of triethylamine, react at room temperature for 24h, TLC thin-layer plate shows that the carboxyl group therein disappears and stops the reaction, and the reaction solution is 5% sodium bicarbonate The solution is quenched, and the product is extracted with an organic solvent B (petroleum ether, ethyl acetate or a mixture of the two), suction filtered, and dried by adding a desiccant under vacuum conditions to obtain end-activated polylactic acid-glycolic acid ,spare; ...

Embodiment 1

[0068] A preparation method of the bioactive glass composite membrane, specifically comprising the following steps:

[0069] 1) Polylactic acid-glycolic acid terminal activation

[0070]

[0071] Dissolve 10 g of polylactic acid-glycolic acid in 30 ml of dichloromethane, add 3.6 g of DCC (N, N-dicyclohexylcarbodiimide) and 2.8 g of N-hydroxy-succinimide, and add 0.5 g of triethyl Amine, reacted at room temperature for 24 hours, TLC thin-layer plate showed that the carboxyl group disappeared and stopped the reaction. The reaction solution was quenched with 50ml of 5% sodium bicarbonate solution, and the product was extracted with 20ml of ethyl acetate, filtered by suction, and added to dryness under vacuum. The agent was dried to obtain 7.3 g of end-activated polylactic acid-glycolic acid, which was set aside;

[0072] 2) Terminal amination synthesis of hyaluronic acid

[0073] Dissolve 3.4g of N,N-diethylethylenediamine in 100ml of phosphate buffer solution with a pH of 8...

Embodiment 2

[0099] An application of the bioactive glass composite film in the preparation of drugs for the auxiliary treatment of periodontitis, the composite film of the present invention is placed in the periodontal pocket during or after the operation, and can be slowly degraded and slowly release biological substances. Active glass nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com