Aquatic feed granulating device for marble goby

A technology of aquatic feed and bamboo shoot shell fish, which is applied in the direction of feed, food science, application, etc., can solve the problems of no electro-hydraulic rod, no aquatic feed speed, flow control, no electromagnetic valve, etc., to achieve control accuracy and Guaranteed flexibility, avoiding the effect of drying aquatic feed and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

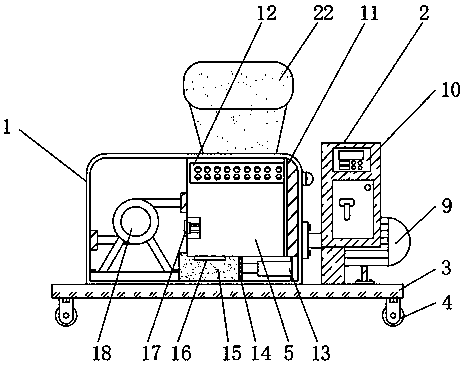

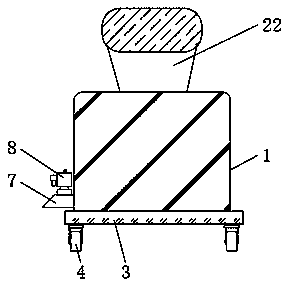

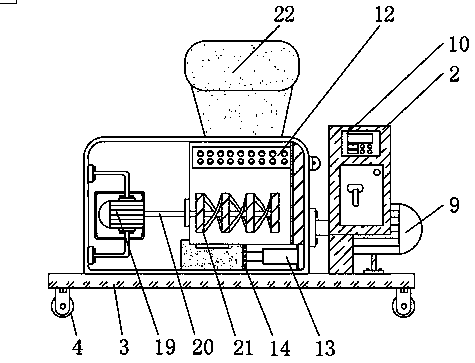

[0028] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, an aquatic feed pellet device for bamboo shoot shell fish, comprising a pellet machine body 1, a working chamber 5 is arranged inside the pellet machine body 1, and the inner bottom of the pellet machine body 1 is close to A blower 18 is provided at one side of the working chamber 5, and a second motor 19 is provided at the inner bottom of the pellet machine body 1 close to the side of the blower 18, and the inner bottom of the pellet machine body 1 is close to the bottom of the working chamber 5 The lower hopper 15 is fixedly connected to the position, the front surface of the pellet machine body 1 is equipped with an inspection door 6, and the upper end of the pellet machine body 1 is provided with a feed port 22, and the rear surface of the pellet machine body 1 is provided with a second discharge. port 7, and the rear surface of the pellet machine body 1 near the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com