A pre-tightening force measuring device for threaded fasteners of oil pipe joints

A technology for threaded fasteners and oil pipe joints, applied to measuring devices, force/torque/work measuring instruments, and measuring torque/torsion force during tightening, can solve problems such as inconvenient maintenance, long cycle time, and low measurement accuracy. Achieve the effect of improving quality, simple operation, and easy popularization and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

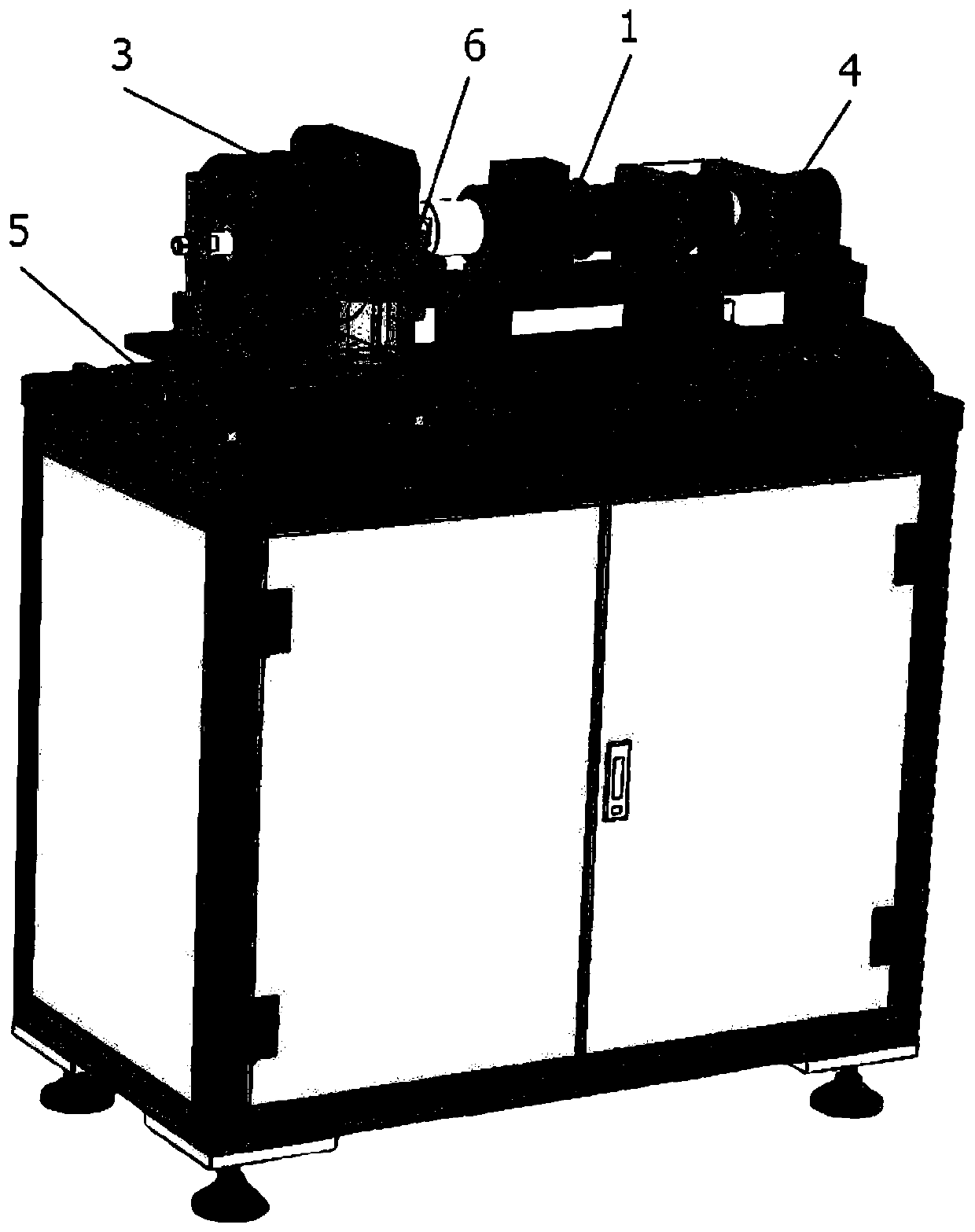

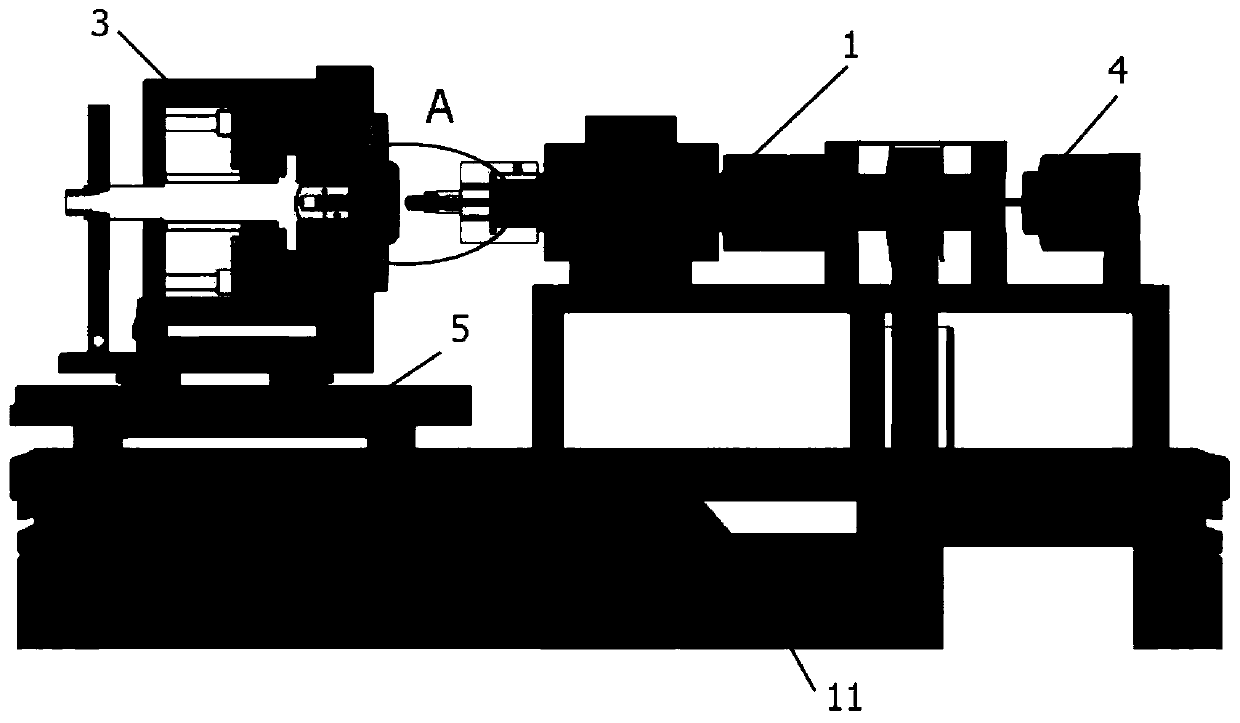

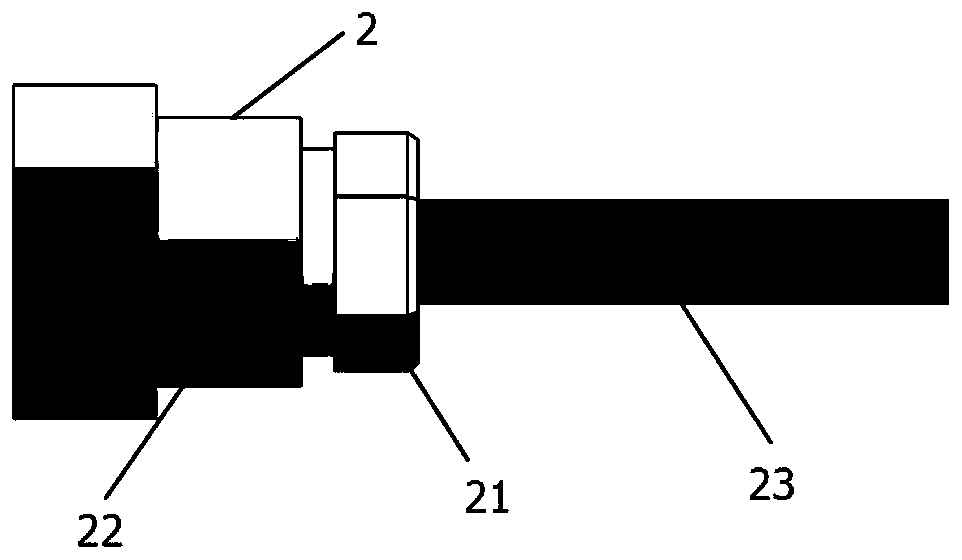

[0028] Refer to attached figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a measuring device for threaded fasteners of oil pipe joints, comprising a torque applying mechanism 1, an external threaded part 21 of the oil pipe joint 2 coaxially connected with the output end of the torque applying mechanism 1, and an external threaded part 21 A matching conversion joint 22, the conversion joint 22 includes a separate internal thread part 221 and a conical surface 222, and a force transmission detection mechanism 3 connected to the conversion joint 22, the force transmission detection mechanism 3 is used to transmit and detect the external thread during the tightening process The pretightening force and frictional torque of the conical surface 222 of the member 21, an oil pipe 23 is arranged inside the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com