Steel wire direct water cooling method and device

A cooling device and direct technology, applied in the direction of wire drawing dies, etc., can solve the problems of cooling and cooling the steel wire, and achieve the effect of reducing the surface temperature of the steel wire, reducing the plasticity loss, and improving the lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

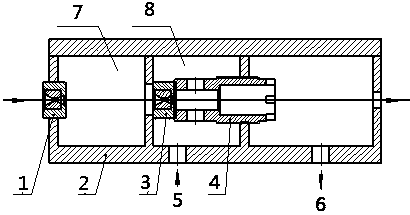

[0015] The steel wire of the present invention directly passes through the water cooling device, and the specific implementation mode is according to figure 1 , It consists of a set die 1, a wire drawing die box 2, a wire drawing die 3, a top wire 4, a water inlet 5, a water outlet 6, a lubricating mold box 7, and a water cooling mold box 8. The drawing die box 2 is provided with a lubricating die box 7 and a water-cooling die box 8. The lubricating die box 7 is provided with a cover die 1, and the water-cooling die box 8 is provided with a drawing die 3, a top wire 4, a water inlet 5 and a water outlet 6.

[0016] The jacking wire 4 is processed with four uniformly distributed waist-shaped through-holes, and the specifications of the through-holes are: length×width×rounded corners: 20mm×10mm×R5mm.

[0017] In the steel wire direct cooling method of the present invention, cooling water is injected through the water inlet 5 to flood the top wire 4 of the steel wire, and the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com