Nut defect detection method and device based on machine vision

A technology of defect detection and machine vision, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as lack of process, incorrect placement of nuts, and no obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

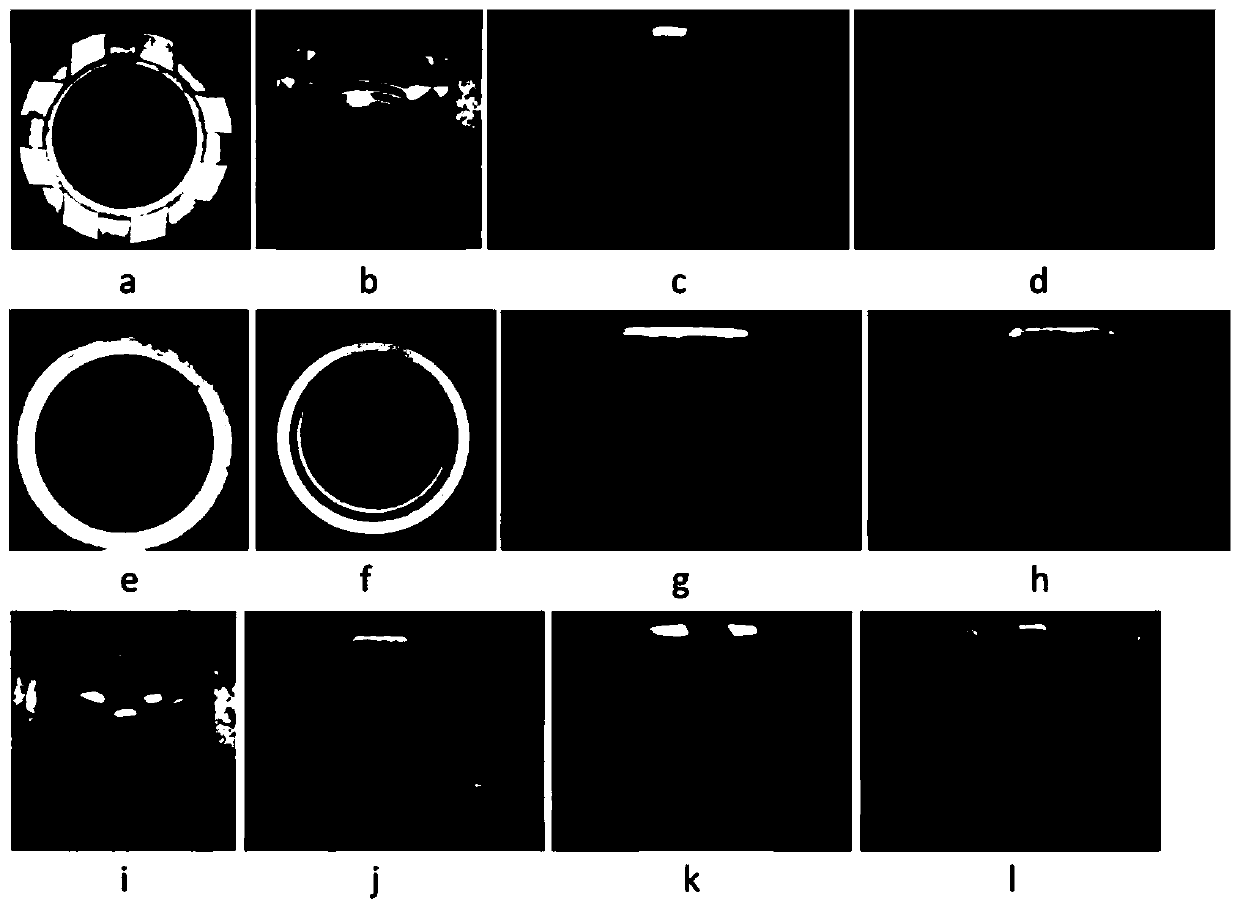

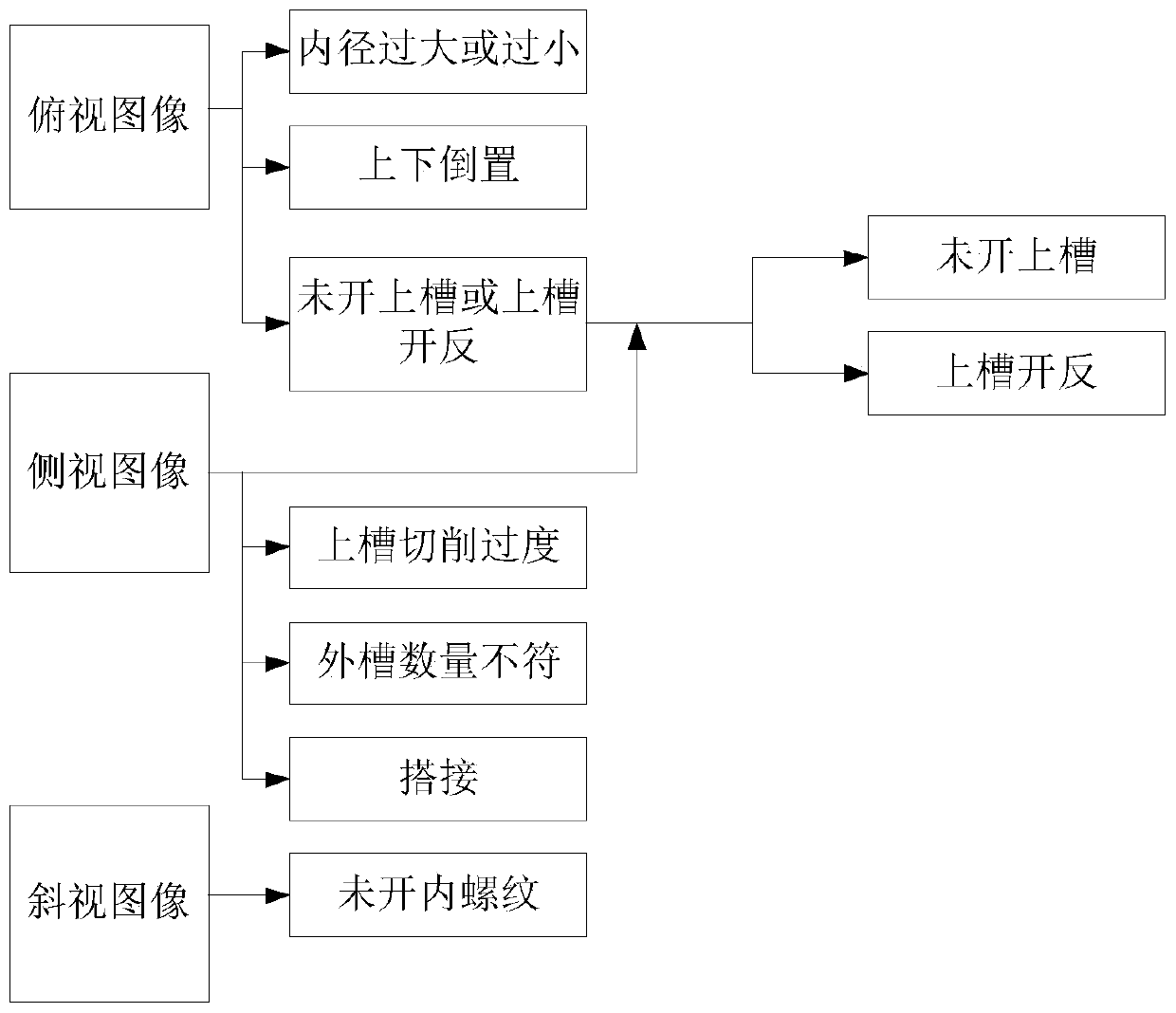

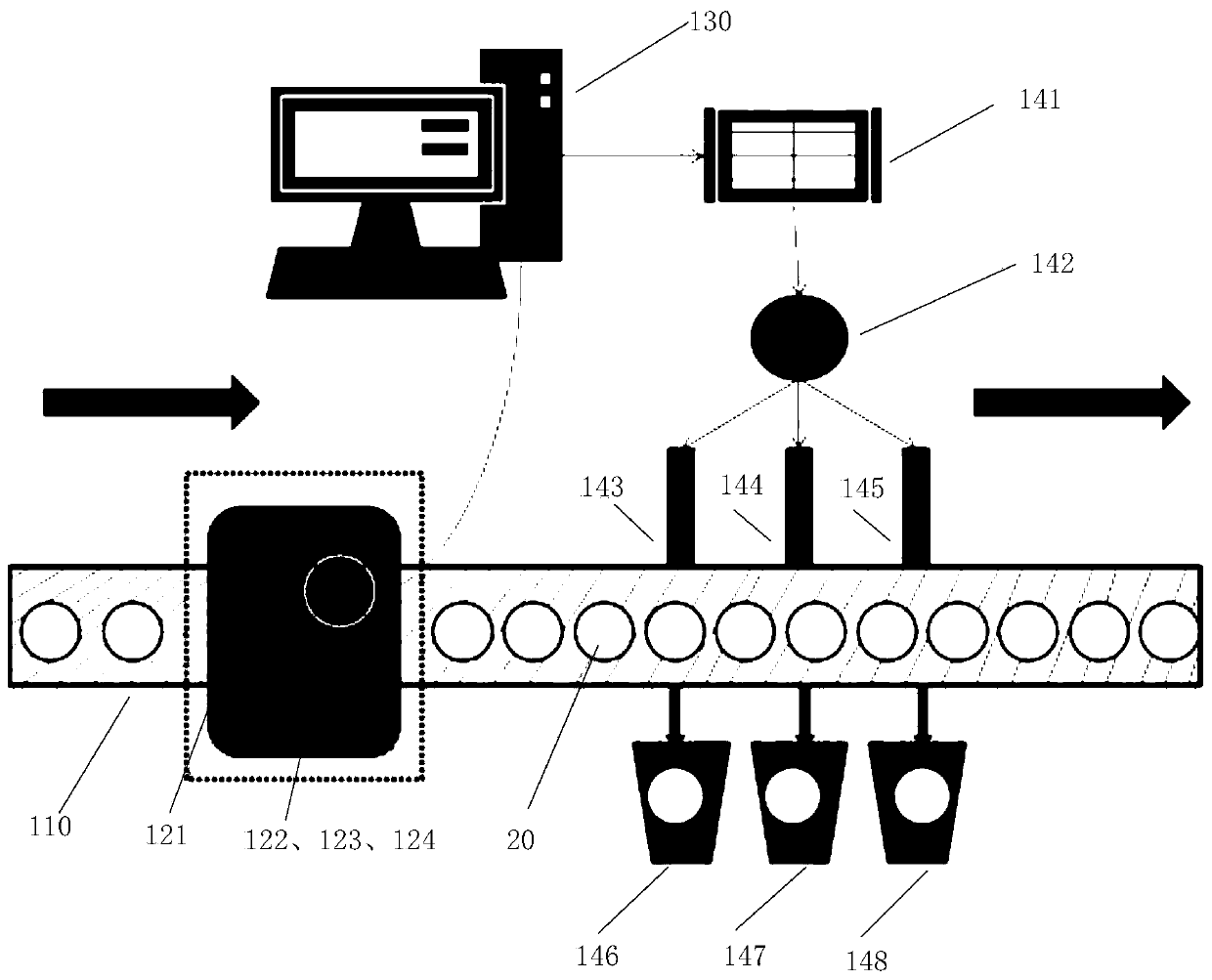

[0121] In addition to the general defects mentioned in the background technology, such as too large or too small inner diameter of the nut, lack of process, and reversed upper groove, there are also a small number of nuts of other types mixed with the nuts to be tested and transported to the quality inspection link. In addition, for the nut automatic quality inspection device based on machine vision technology, there are also situations where nuts are placed incorrectly and nuts overlap. The former means that the nuts enter the quality inspection equipment with the bottom facing up on the assembly line, and the latter is Multiple nuts are stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com