A kind of laying hen feed using Leucaena microphylla as raw material and preparation method thereof

A technology of laying hen feed and leucaena, which is applied in the field of laying hen feed and its preparation, can solve the problems of reducing the disease resistance of laying hens and affecting the absorption of nutrients eaten by laying hens, so as to improve disease resistance, increase the probability of collision, The effect of promoting fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

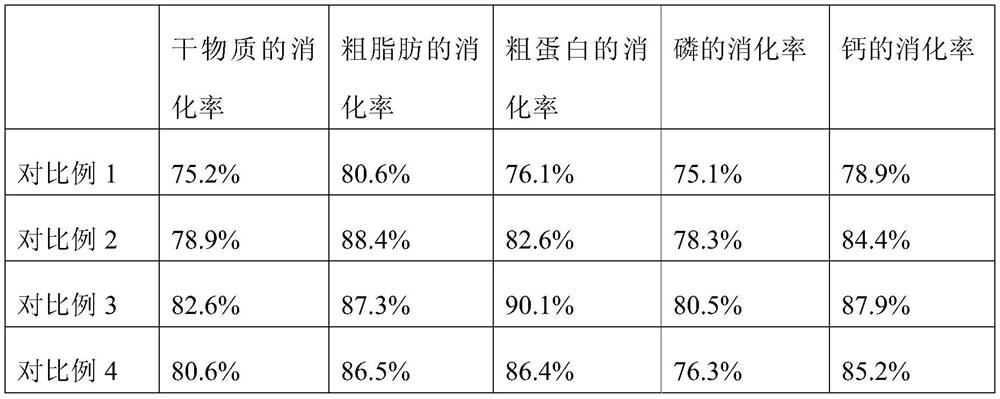

Examples

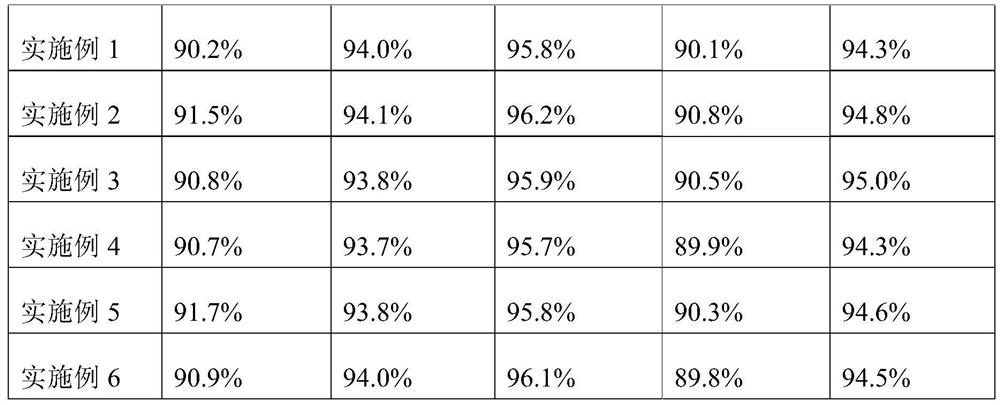

Embodiment 1

[0036] 1. Preliminary preparation

[0037] Preparation of carboxymethyl chitosan solution mixture: in parts by weight, 25 parts of carboxymethyl chitosan and 100 parts of deionized water are put into the reactor, the temperature is raised to 45°C, the stirrer is started, and the temperature is set at 1000r / The rotating speed of min was stirred, and then 10 parts of seaweed polysaccharide solutions with a mass fraction of 15% were injected into the above-mentioned solution system at a speed of 10 m / s, and after stirring at a constant speed for 35 min, the carboxymethyl chitosan solution mixture was obtained.

[0038] Preparation of the additive: in parts by weight, 5 parts of vitamins, 2 parts of trace metal elements and 1 part of somatotropin are mixed to obtain the additive. Wherein the content of copper ions in somatotropin is 75000mg / kg, the content of iron ions is 3000mg / kg, and the content of zinc ions is 5000mg / kg.

[0039] The substances prepared above were used in the ...

Embodiment 2

[0046] Preparation of carboxymethyl chitosan solution mixture: in parts by weight, 25 parts of carboxymethyl chitosan and 100 parts of deionized water are put into the reactor, the temperature is raised to 45° C. The rotating speed of min was stirred, and then 10 parts of seaweed polysaccharide solutions with a mass fraction of 16% were injected into the above-mentioned solution system at a speed of 10 m / s, and after stirring at a constant speed for 40 min, the carboxymethyl chitosan solution mixture was obtained.

[0047] Preparation of the additive: in parts by weight, 10 parts of vitamins, 3 parts of trace metal elements and 1 part of somatotropin are mixed to obtain the additive. Wherein the content of copper ions in somatotropin is 77000mg / kg, the content of iron ions is 3200mg / kg, and the content of zinc ions is 5500mg / kg.

[0048] The substances prepared above were used in the production methods described below.

[0049] 2, a kind of preparation method of laying hen fe...

Embodiment 3

[0055] Preparation of carboxymethyl chitosan solution mixture: in parts by weight, 25 parts of carboxymethyl chitosan and 100 parts of deionized water are put into the reactor, the temperature is raised to 45°C, the stirrer is started, and the The rotation speed of min was stirred, and then 10 parts of seaweed polysaccharide solutions with a mass fraction of 17% were injected into the above solution system at a speed of 10 m / s, and after stirring at a constant speed for 50 min, the carboxymethyl chitosan solution mixture was obtained.

[0056] Preparation of the additive: in parts by weight, 10 parts of vitamins, 3 parts of trace metal elements and 1 part of somatotropin are mixed to obtain the additive. Wherein the content of copper ions in somatotropin is 80000mg / kg, the content of iron ions is 3500mg / kg, and the content of zinc ions is 5400mg / kg.

[0057] The substances prepared above were used in the production methods described below.

[0058] 2, a kind of preparation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com