Method for detecting movement of aramid conveyor belt finger-type connector by X rays

A technology of finger joints and conveyor belts, which is applied in the field of X-ray detection of finger joint twitching of new aramid conveyor belts, which can solve the problems of difficult steel wire rope bonding, low joint safety factor, low joint strength retention rate, etc., and achieve reduction The effect of flipping through time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

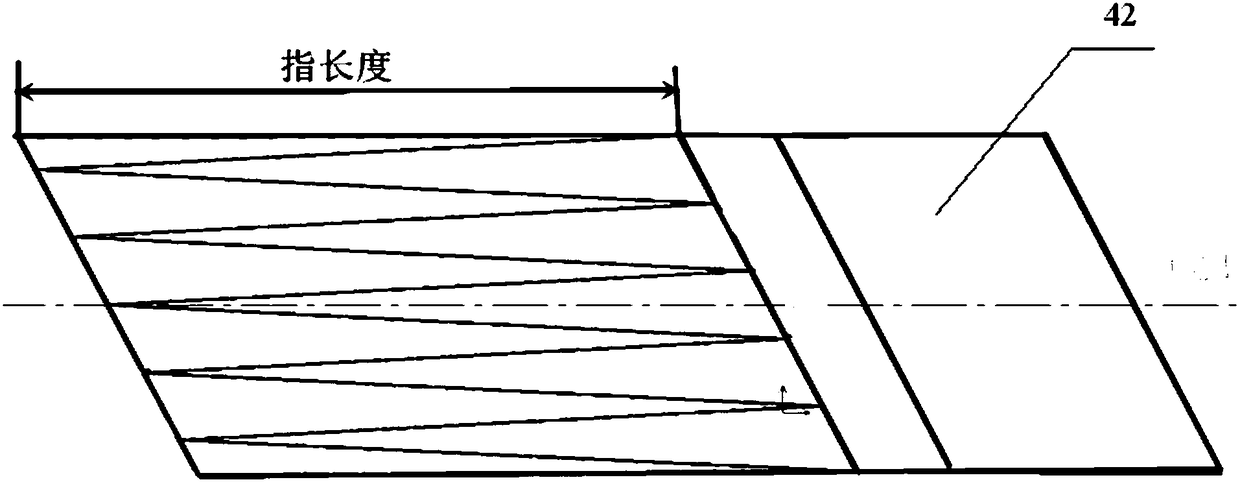

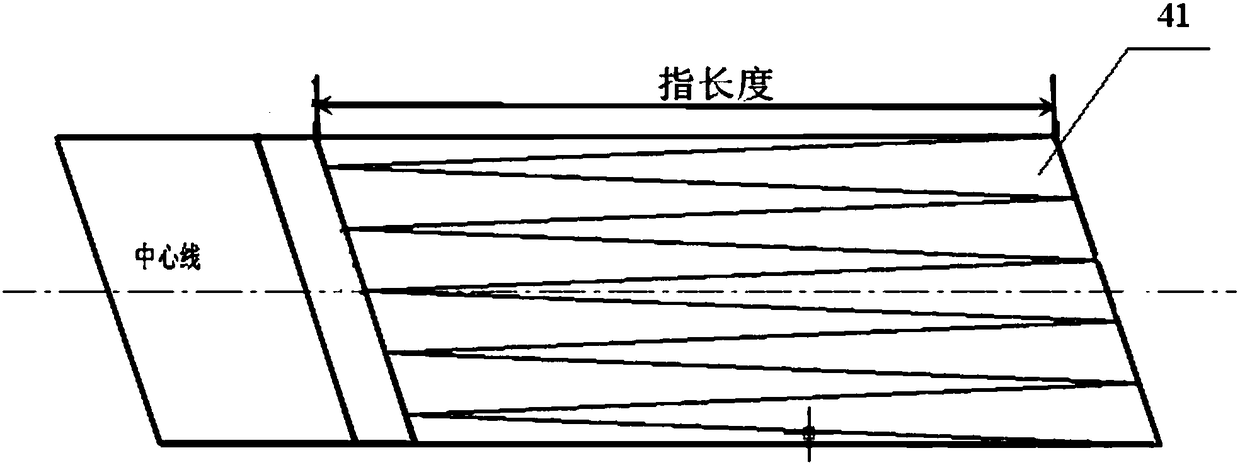

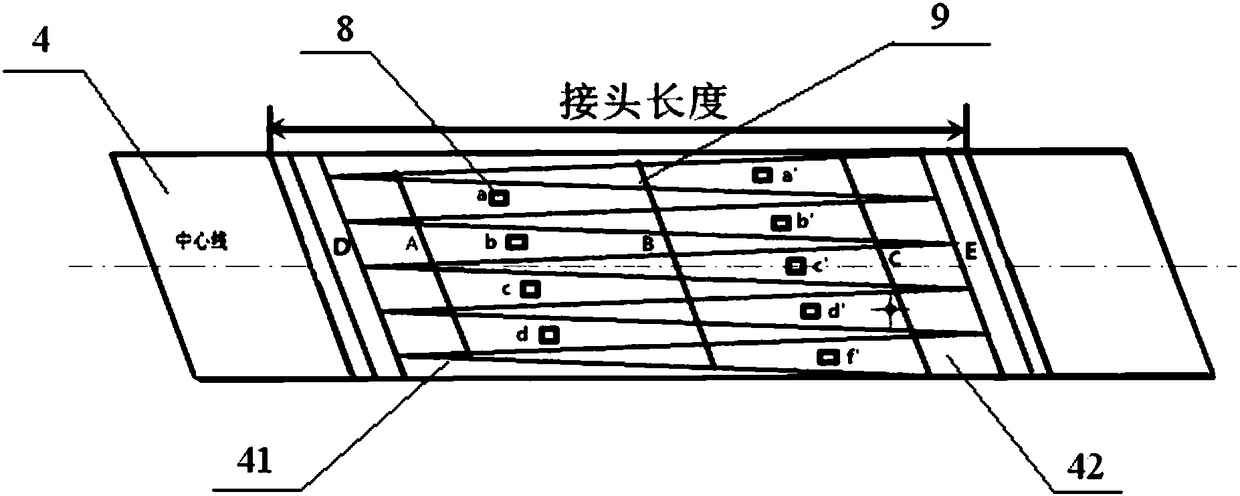

[0035] Such as Figure 1-4 As shown, an X-ray detection aramid conveyor belt finger joint includes an upper cover rubber 1, an upper reinforcement cloth 2, a first adhesive 3, an aramid core 4, a second adhesive 5, a lower reinforcement cloth 6 and The lower cover glue 7, the above materials are arranged sequentially from top to bottom; the aramid tape core 4 is spliced by the first finger joint 41 and the second finger joint 42; the first glue 3 is provided with several A metal block 8 and a metal rope 9.

[0036] The metal blocks 8 are distributed at adjacent finger positions of the corresponding first finger joints 41 and second finger joints 42 . The metal rope 9 is located at the joining joint of the first finger joint 41 and the second finger joint 42, and the direction is perpendicular to the extending direction of the conveyor belt.

[0037] The length and width of the metal block 8 are both 1.85-2.15mm, and the thickness is 0.99-1.29mm; the diameter of the metal r...

Embodiment 2

[0038] Example 2 X-ray detection method for finger joint displacement of aramid conveyor belt, the specific steps are as follows:

[0039] (1) Finger cutting of aramid conveyor belt: cut the joint area at both ends of the single-layer aramid conveyor belt (such as Figure 1-2As shown), according to the specified joint finger length and finger width, use a special cutting knife to cut the finger shape. When cutting, follow the principle of removing more and leaving less, and remove the excess to keep the cloth surface clean and flat. Facilitate the expansion of the splicing process;

[0040] (2) Spread joint rubber material: according to the conveyor belt joint process, on the heating plate under the joint vulcanizer, cut the corresponding size according to the length of the aramid conveyor belt joint and the thickness of the film, lay the lower rubber material flatly, and then place the previously cut sheet Layers of aramid fingers, aligned to the centerlines of the splice en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com