Device for preventing burner nozzle from bonding slag, with axial adjustable blades

A burner nozzle and burner technology, which is applied in the field of combustion, can solve problems such as burner nozzle slagging, and achieve the effects of preventing burner nozzle slagging, increasing swirl intensity, and strengthening ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

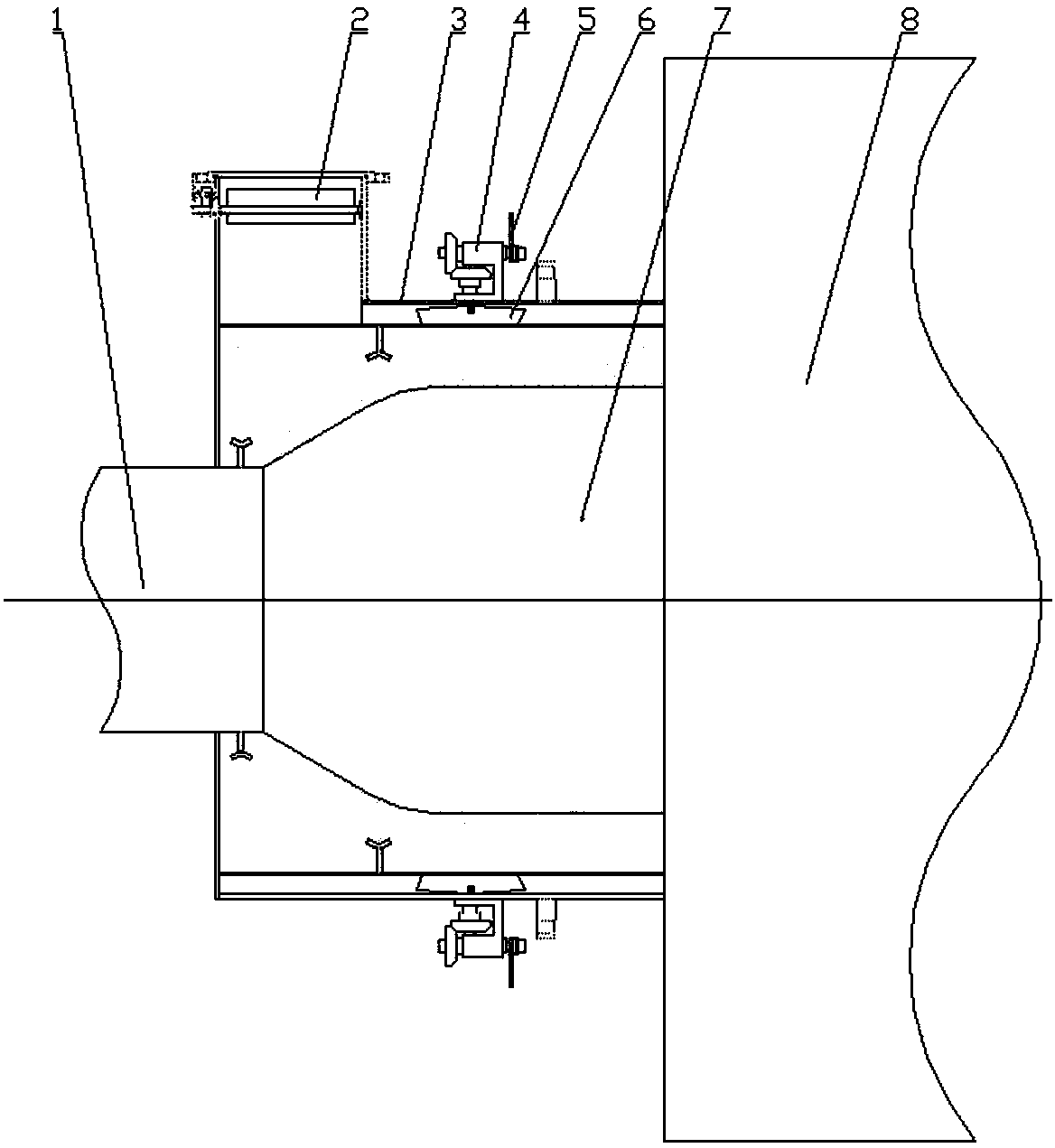

[0018] refer to figure 1 , the device with axially adjustable blades to prevent slagging at the burner nozzle according to the present invention includes a pre-combustion chamber 7, a burner body 1 and a furnace 8, wherein the outer wall of the pre-combustion chamber 7 is provided with a remote exhaust air duct 3 , wherein the burner main body 1 is connected to the entrance of the pre-combustion chamber 7, the nozzle of the pre-combustion chamber 7 and the outlet of the remote overfired air duct 3 are connected to the boiler furnace 8, and the remote overfired air duct 3 is set There are a number of axial blades 6 for adjusting the swirling strength of the remote overburning air. The outer wall of the remote overburning air duct 3 is provided with a linkage adjustment device for adjusting the angle of the axial blades 6. During work, according to the coal quality and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com