Heat and power synergistic system and method based on reheating and heat accumulation adjustment

A thermoelectric synergy and heat regulation technology, applied in heating systems and centralized heating, can solve the problems of high-grade steam demand of heat users that cannot be solved, occupy a large space, and low-grade heat energy, etc., to improve the effect of thermoelectric systems, Small footprint and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

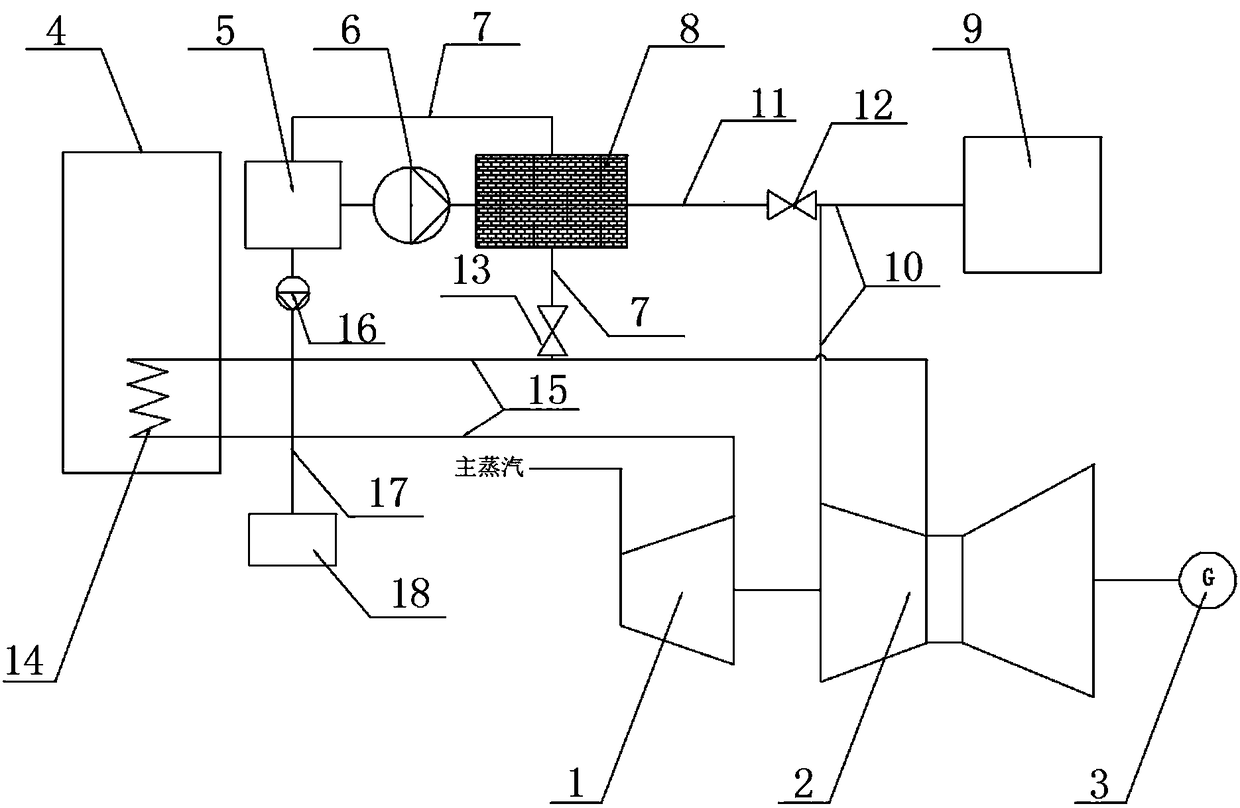

[0020] like figure 1 As shown, a thermoelectric synergy system based on reheat heat storage adjustment, including high pressure steam turbine 1, medium and low pressure steam turbine 2, generator 3, boiler 4, hot water tank 5, heat storage steam make-up water pump 6; reheat heat storage side Road 7, heat accumulator (8), heat supply station 9, steam extraction heat supply branch 10, heat storage steam supply branch 11, heat storage steam supply control valve 12, reheat heat storage bypass valve 13, reheat Device 14, reheating branch 15, hot water heat supply pump 16, hot water heating branch 17, hot water user 18. The high-pressure steam turbine 1, the medium-low pressure steam turbine 2, and the generator 3 are connected in sequence, and the outlet of the high-pressure steam turbine 1 is connected to the reheater 14 in the boiler 4 and the inlet of the medium-pressure cylinder of the medium-low pressure steam turbine 2 through the reheat branch 15 in sequence. The outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com