Time-delay water filling water intake rod

A water inlet and water tank technology, which is used in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of slow, unscientific water inlet rods, affecting the service life of valves, etc., and achieves short opening and closing time and service life. Long, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

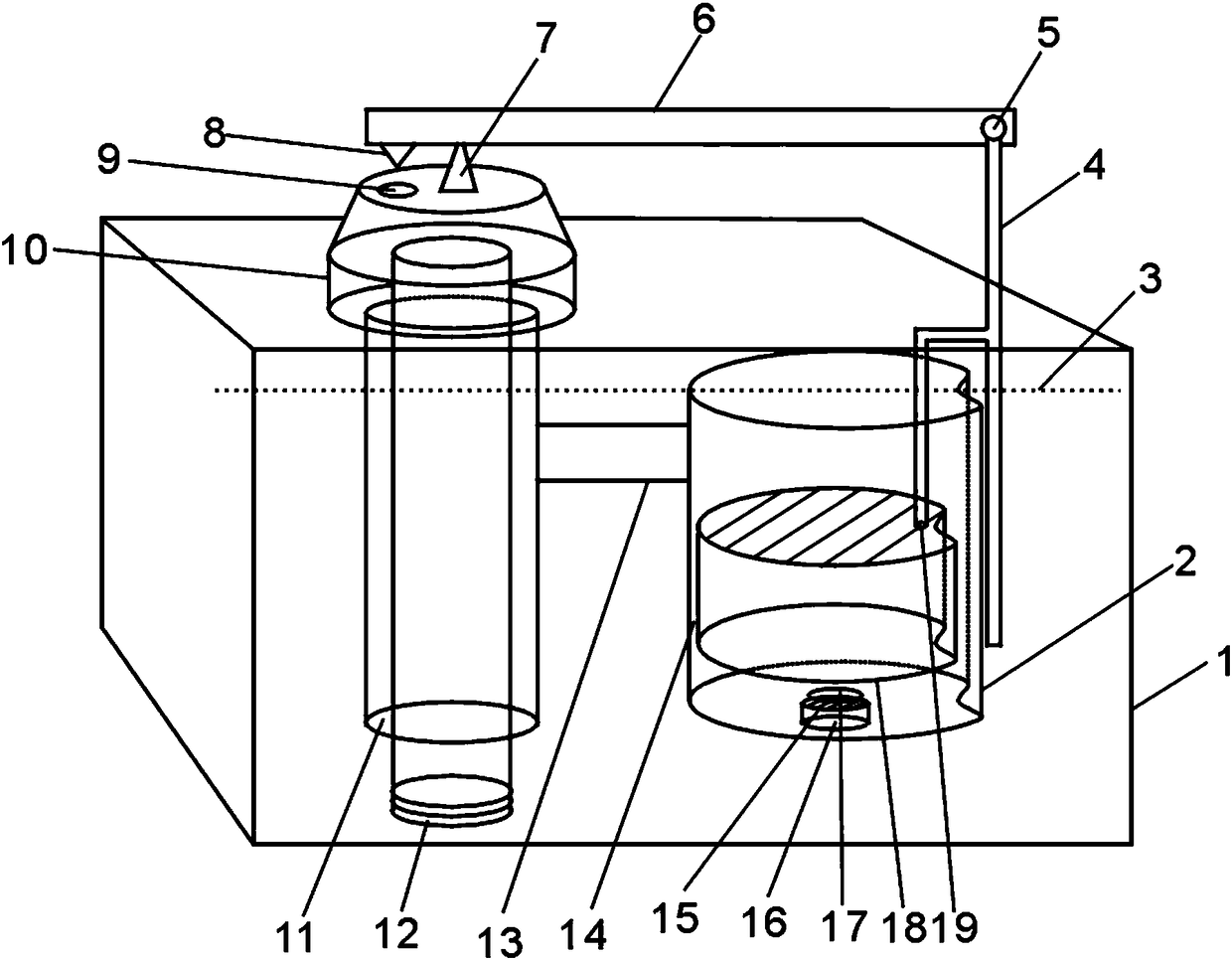

[0016] figure 1 Shown is the specific implementation of the water inlet rod for delaying water addition of the present invention. Main fittings such as differential pressure valve 10 in the water tank 1 and put float cover 2 along and installation form all do not have difference with common water inlet bar. The fixing bracket 13 forms an integral body with the differential pressure valve 10 and the parallel float 2 . One end of the lever 6 has a stopper 8 to coincide with the pressure relief hole 9, and the other end makes the transmission rod 4 drive the float linkage rod 19 by the joint 5. The float link 19 is formed together with the inverted float 18 . The slits around the facings of the upside-down floats 18 embedded in the float cover 2 are very small, and are called the slits 14 between the floats. Bottom seal small float 16, bottom seal sealing mouth 15 coincide with the bottom seal water leakage port 17 of placing float cover 2 bottoms in order as a whole. The dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com