Hydro cleaner and micro-mist dust suppression device

A cleaner and hydraulic technology, applied in the field of environmental protection equipment, can solve the problems of wasting resources, inconvenient use of hydraulic cleaners, etc., and achieve the effects of energy saving, simple and reasonable structure, and convenient manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

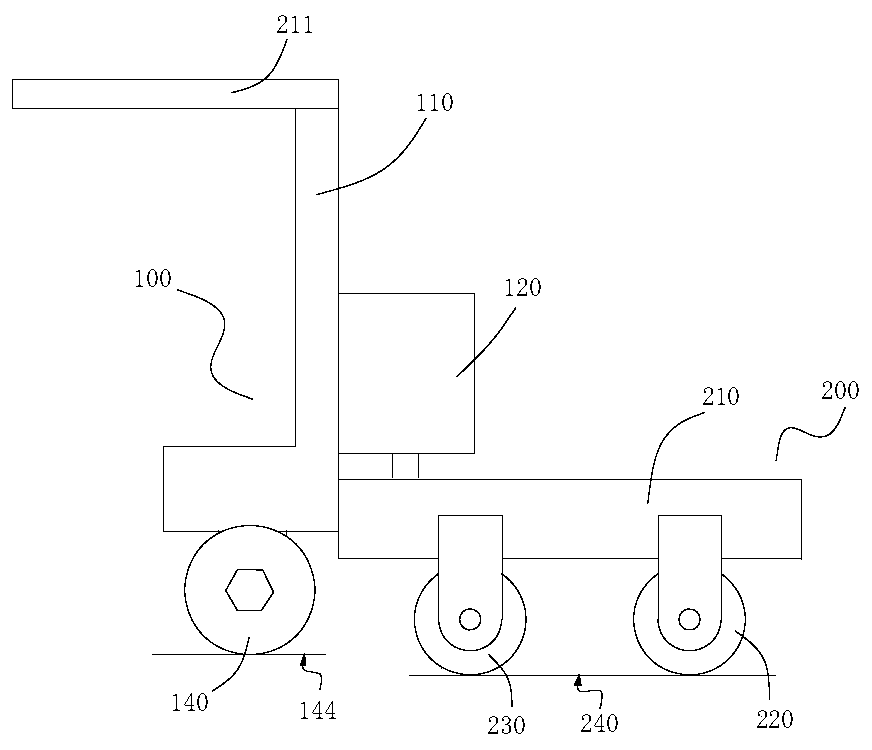

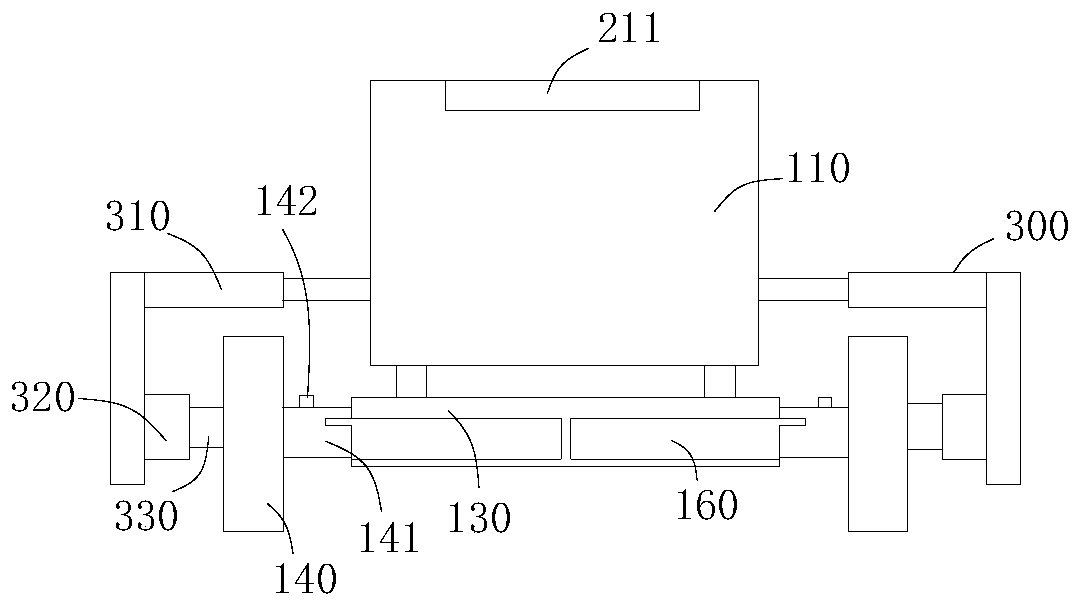

[0045] see figure 1 - Figure 9 , this embodiment provides a hydraulic cleaner, which includes a flushing mechanism 100 and a walking mechanism 200 .

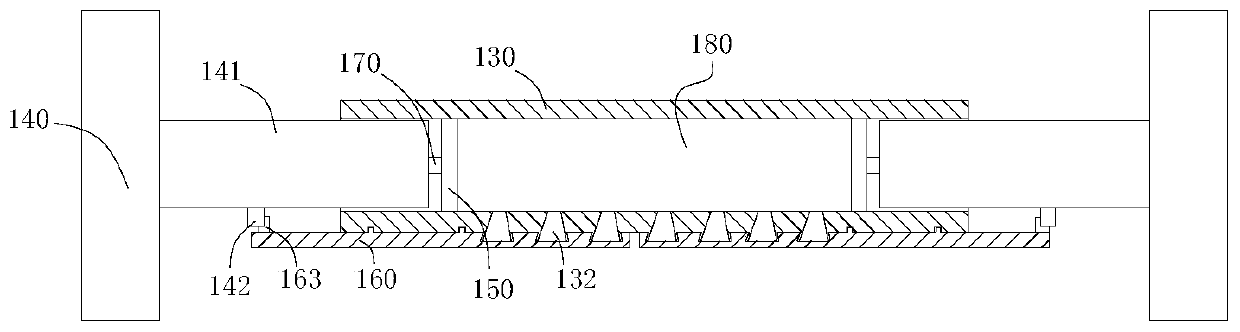

[0046] In this embodiment, the flushing mechanism 100 includes a mounting frame 110, a water tank 120, a flushing pipe 130, two pressurizing wheels 140, two sealing sliding members 150, and at least one shutter 160. The water tank 120 and the flushing pipe 130 are all installed in the installation rack 110.

[0047] The flushing pipe 130 is cylindrical, both ends of the flushing pipe 130 are open, and internal threads are respectively provided on the inner pipe walls of the two ends of the flushing pipe 130 . A water inlet 131 and at least one water outlet 132 are arranged on the wall of the flushing pipe 130. The water inlet 131 is connected to the water tank 120 through a hose, and a valve can be set on the water tank 120 to control the on-off of the water inlet 131 and close the valve. After that, the water in the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com