A novel synthetic method of polyaspartic polyurea resin

A technology of aspartame polyurea resin and a new method, applied in the chemical industry, can solve the problems of high cost, long delivery time, long production cycle, etc., and achieve the effects of short synthesis time, improved protective performance and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

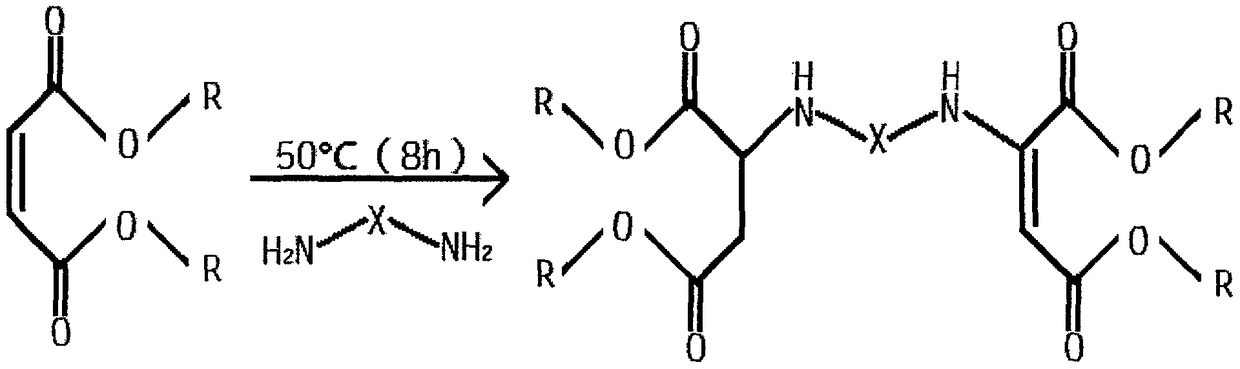

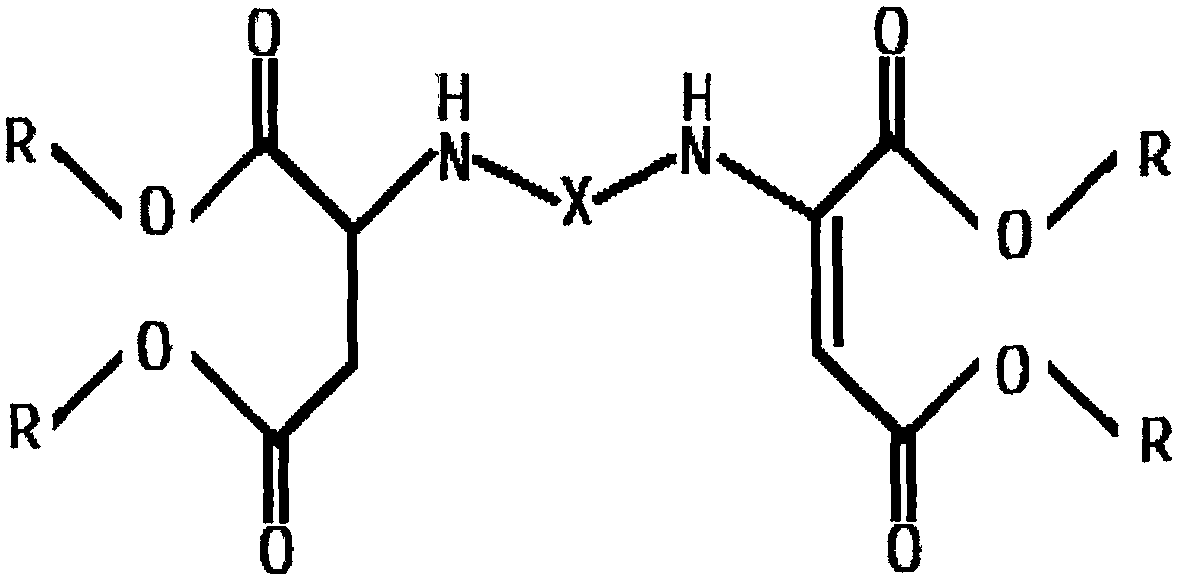

[0014] Such as figure 2 Shown, this aspartic polyurea resin synthetic new method comprises the steps:

[0015] (1) Slowly add multifunctional organic primary amines dropwise to excess dialkyl maleic acid esters (30% of the total excess amount), and cool down while stirring. Incubate at 50°C for 8 hours after adding, take a sample for inspection after 8 hours, when no residual primary amine is detected, the reaction is considered complete, the synthesis is terminated, and the product enters the next production section as a semi-finished product;

[0016] (2) Put the synthesized semi-finished product into a rotary evaporator or a molecular distillation apparatus, and paint or scrape the semi-finished product into a film under the conditions of a vacuum degree of 10 Pa and a temperature of 80-100 ° C. Dialkyl maleate in the semi-finished product It is quickly vaporized and enters the condenser, and is collected together after becoming a liquid, and then used as a raw material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com