A kind of high cross-linking degree polymer microspheres with super macropores and preparation method thereof

A technology with high cross-linking degree and polymer is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc. It can solve the problems of low cross-linking degree of polymer microspheres and difficulty in preparing polymer microspheres, etc. Achieving the effect of wide range of polymerization temperature, mild reaction and high degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of highly cross-linked polymer microspheres with super large pores, comprising the steps of:

[0033] Step A, dissolving stabilizer and surfactant in deionized water to form a homogeneous solution to obtain an aqueous phase solution.

[0034] Step B, dissolving the vinyl monomer and divinyl crosslinking agent in the porogen solution, filling nitrogen and deoxygenating, adding an atom transfer radical polymerization initiator system, making the atom transfer radical polymerization initiator The system accounts for 8% of the sum of the moles of the vinyl monomer and the divinyl crosslinking agent to form a uniform solution and obtain an oil phase solution.

[0035] Step C. Add the oil phase solution to the water phase solution under the conditions of nitrogen filling and stirring, and the volume ratio of the oil phase solution to the water phase solution is 1:9 to 1:4 And carry out a temperature-rising polymerization reaction, the reaction temperature ...

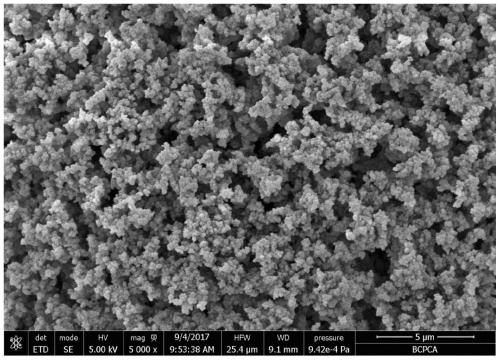

Embodiment 1

[0048] A preparation method of highly cross-linked polymer microspheres with super large pores, comprising the steps of:

[0049] Step a1. Preparation of aqueous phase solution: Dissolve 6 g of polyvinyl alcohol with a molecular weight range of 60,000 and 3.3 g of sodium dodecylbenzenesulfonate in 100 mL of deionized water, and stir until uniform and transparent to form a uniform solution to obtain an aqueous phase solution.

[0050] Step b1, oil phase solution preparation: according to the volume ratio of glycidyl methacrylate (GMA) and ethylene glycol dimethacrylate (EDMA) is 1:10, and the total volume of GMA and EDMA and porogen The volume ratio is 1:4, GMA and EDMA are dissolved in the porogen solution, stirred until uniform and transparent, and after filling nitrogen and deoxygenating, add atom transfer radical polymerization initiator system (in this atom transfer radical In the polymerization initiator system, cuprous chloride and 2,2-bipyridine are used as the ligand s...

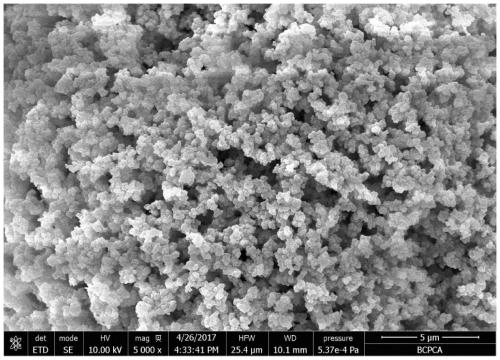

Embodiment 2

[0054] A preparation method of highly cross-linked polymer microspheres with super large pores, comprising the steps of:

[0055] Step a2, preparation of aqueous phase solution: Dissolve 6 g of polyvinyl alcohol with a molecular weight of 60,000 and 6 g of sodium stearate in 100 mL of deionized water, and stir until uniform and transparent to form a uniform solution to obtain an aqueous phase solution.

[0056] Step b2, oil phase solution preparation: according to the volume ratio of styrene (St) and polyethylene glycol dimethacrylate (PEGDMA) is 1:6, and the volume ratio of the total volume of St and PEGDMA and porogen is Dissolve St and PEGDMA in the porogen solution at a ratio of 1:5, stir until uniform and transparent, and after filling nitrogen and deoxygenating, add the atom transfer radical polymerization initiator system (in this atom transfer radical polymerization initiator In the system, copper bromide and tetramethylethylenediamine (TMEDA) are used as the ligand sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com