Preparation method of 4-aminodiphenylamine

A technology of aminodiphenylamine and nitrodiphenylamine, which is applied in the field of preparation of 4-aminodiphenylamine and can solve the problems of low catalyst recycling rate, low product purity or production capacity, equipment corrosion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

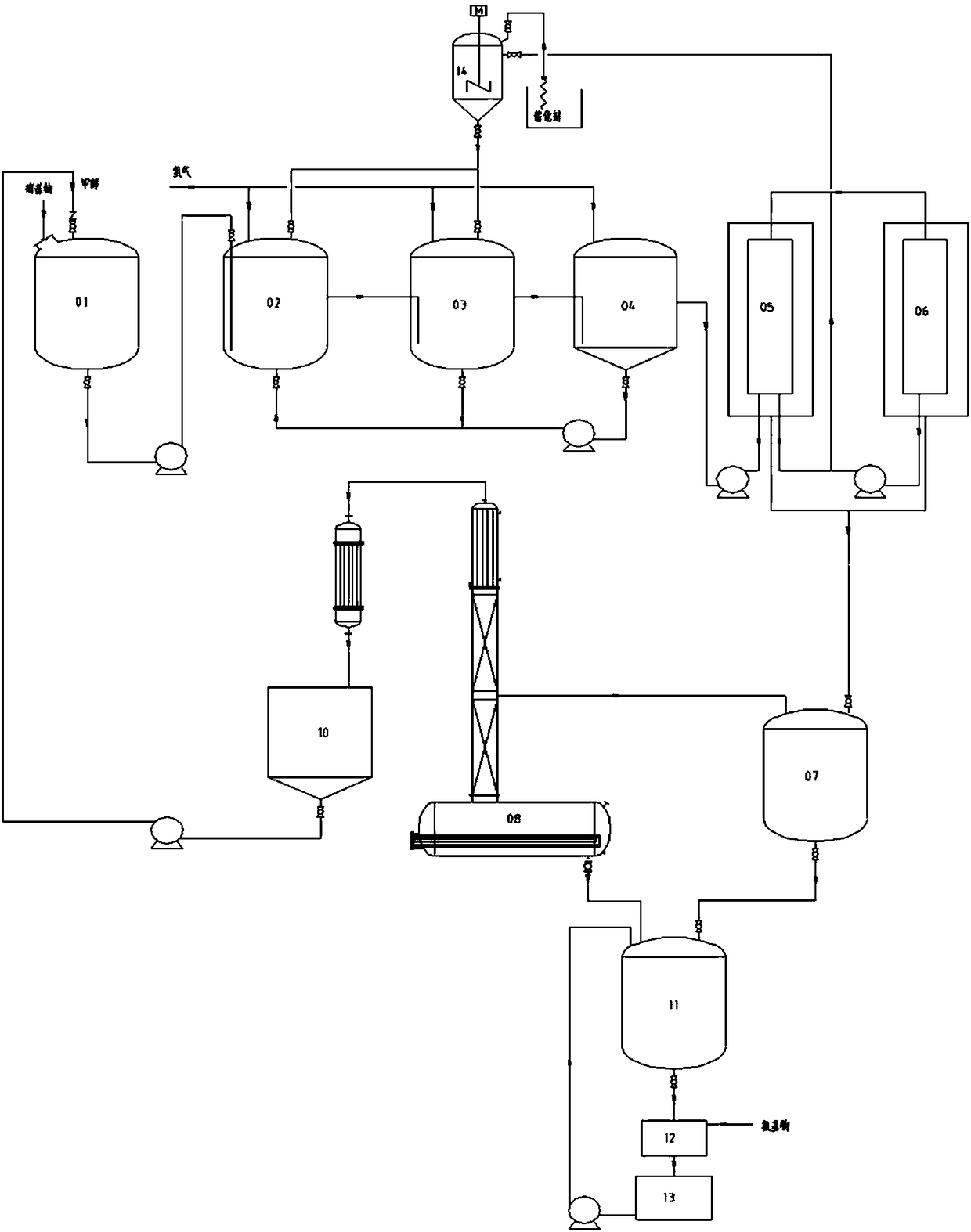

[0092] A preparation method of 4-aminodiphenylamine, using 4-nitrodiphenylamine as raw material, adopting ReneyNi catalyst, carrying out continuous catalytic hydrogenation reaction in a reactor, after the catalyst is separated and recovered, the reducing solution is desolvated and purified to obtain The target product 4-aminodiphenylamine.

[0093] Specific steps include:

[0094](1) Put 5000kg of methanol and 1250kg of 4-nitrodiphenylamine into the chemical material tank, follow-up feeding is carried out according to the ratio, stir evenly, pump them into the first-stage hydrogenation reactor, add ReneyNi catalyst 125kg, the particle size of the catalyst The diameter is 10nm, pass through the nitrogen replacement system three times, then pass through the hydrogen replacement system three times, start stirring, raise the temperature to 90-100°C, and pump 4-nitrodiphenylamine into the primary hydrogenation tank at a flow rate of 6000L / h The raw material solution, into the H 2...

Embodiment 2

[0098] (1) Put 5000kg of methanol and 1250kg of 4-nitrodiphenylamine into the chemical tank, follow up the feeding according to the ratio, stir evenly, pump them into the first-stage hydrogenation reactor, add 125kg of ReneyNi catalyst, the particle size of the catalyst 500μm; pass through the nitrogen replacement system three times, then pass through the hydrogen replacement system three times, start stirring, raise the temperature to 80-90°C, and pump 4-nitrodiphenylamine into the first-stage hydrogenation tank at a flow rate of 5000L / h Raw material liquid, pass into H 2 , the hydrogen pressure in the control system is 3.0MPa, and 2.5kg of ReneyNi catalyst is added to the primary hydrogenation reactor every 3 hours. After the material in the primary hydrogenation reactor gradually increases, it flows into the secondary reactor through the overflow port. In the hydrogenation kettle, the material stays in the hydrogenation kettle for about 2-3 hours. After the reaction is qual...

Embodiment 3

[0102] (1) 12500kg of methanol and 1250kg of 4-nitrodiphenylamine are put into the chemical material tank, and the subsequent feeding is stirred evenly according to the ratio. The diameter is 10nm; pass through the nitrogen replacement system three times, then pass through the hydrogen replacement system three times, start stirring, raise the temperature to 90-100°C, and pump 4-nitrodiphenylamine into the first-stage hydrogenation tank at a flow rate of 6000L / h The raw material solution, into the H 2 , the hydrogen pressure in the control system is 3.0MPa, and 2.5kg of ReneyNi catalyst is added to the primary hydrogenation reactor every 3 hours. After the material in the primary hydrogenation reactor gradually increases, it flows into the secondary reactor through the overflow port. In the hydrogenation kettle, the material stays in the hydrogenation kettle for about 2-3 hours. After the reaction is qualified (4-nitrodiphenylamine residue ≤ 0.2%), the secondary hydrogenation k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com