Chain production process and pin fillet processing device applied to this process

A production process and chain technology, applied in the field of pin shaft fillet processing devices, can solve problems such as low processing efficiency, and achieve the effects of improving efficiency, reducing processing costs, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

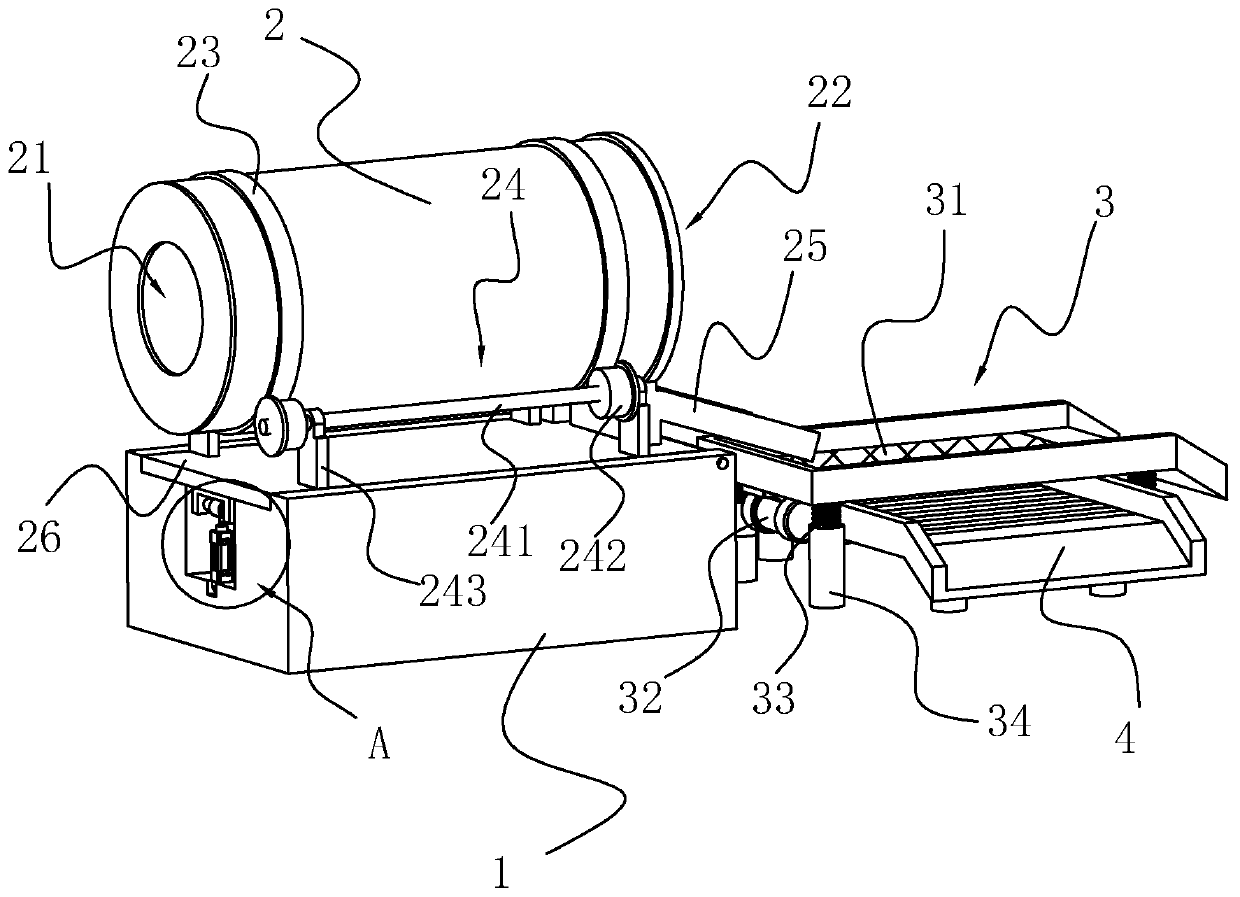

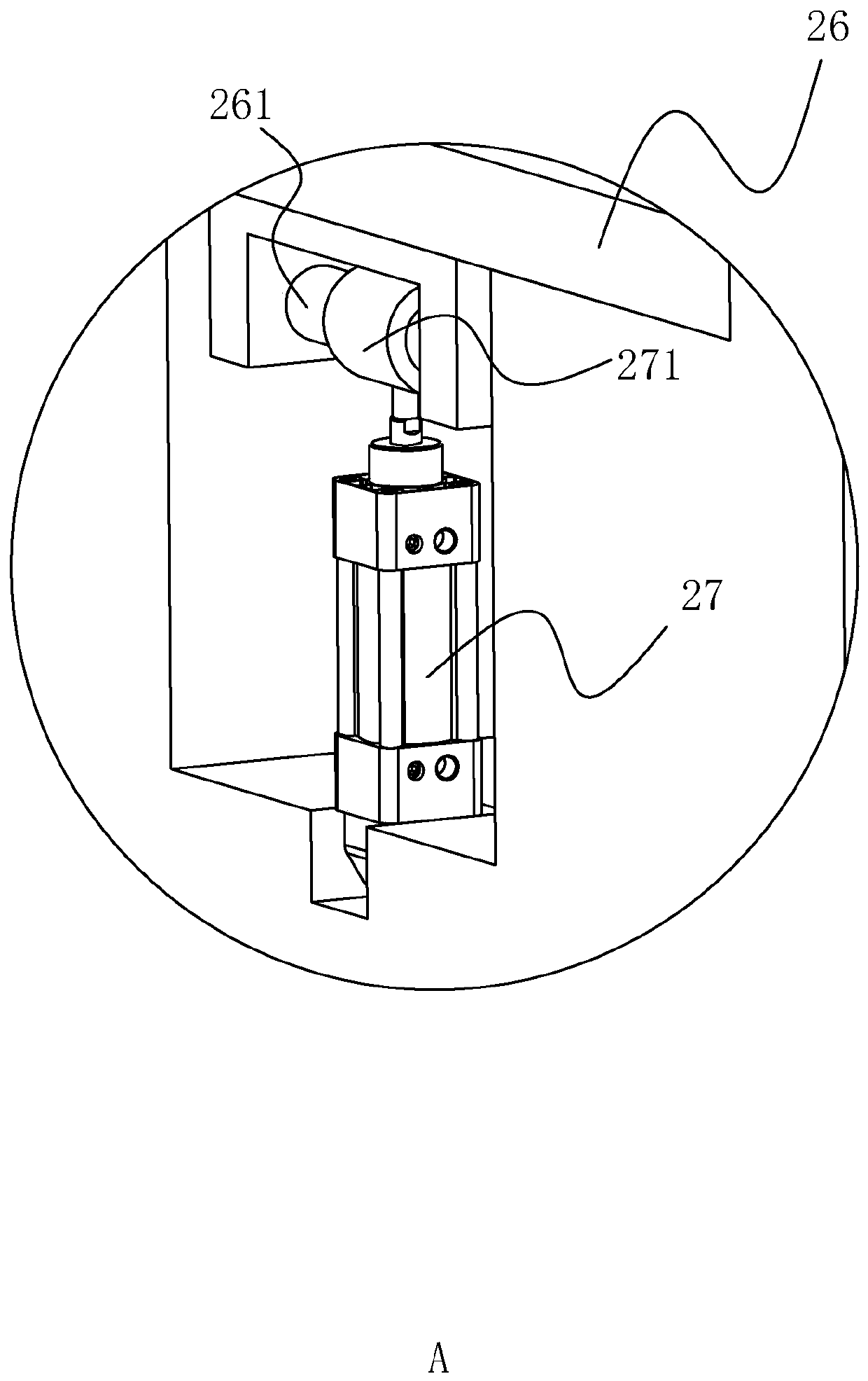

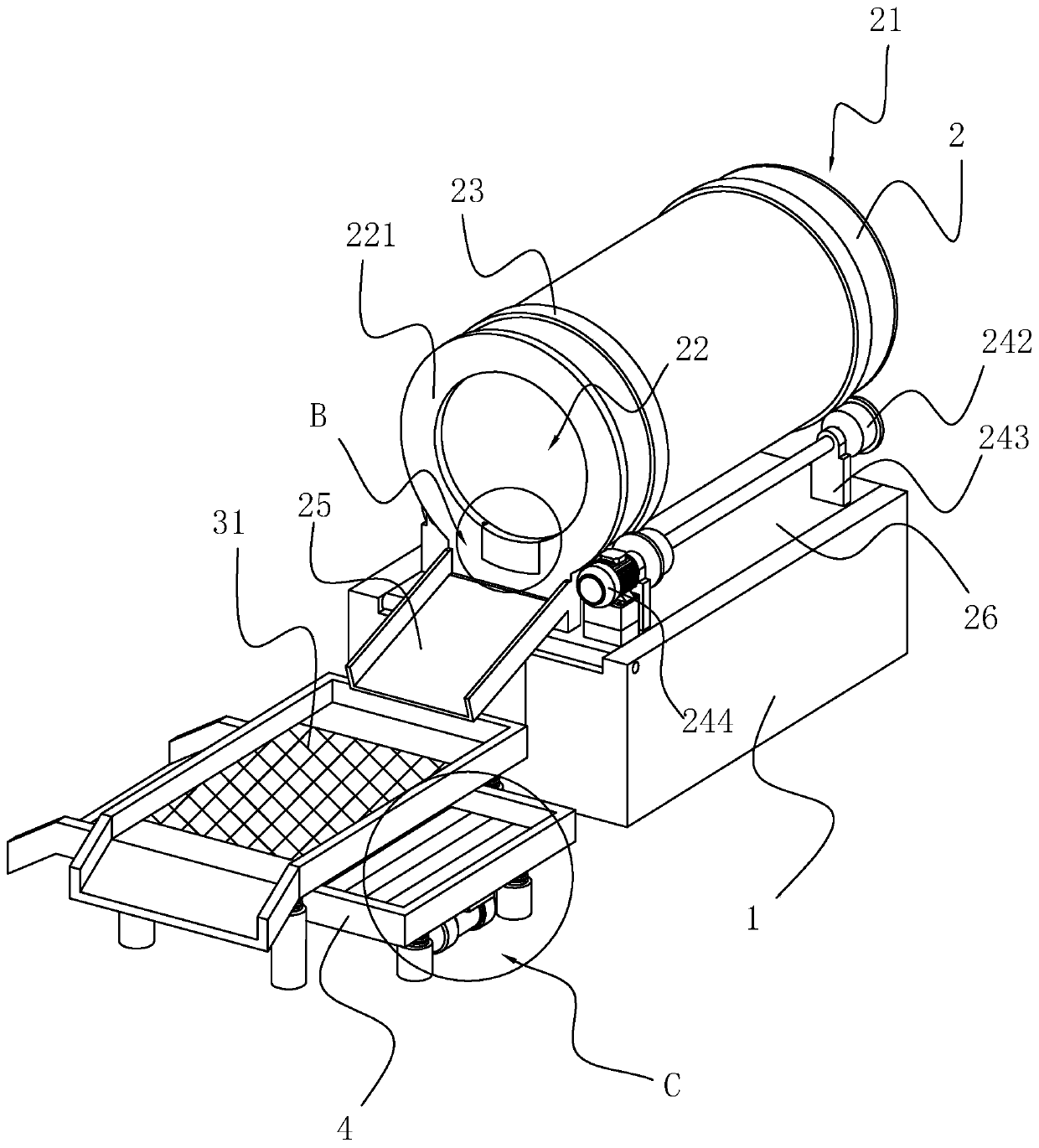

[0043] Embodiment 1: A processing device for rounded corners of pin shafts, used for processing rounded corners of pin shafts, see attached figure 1 , including a workbench 1, a base plate 26 arranged on the workbench 1, a drum 2 arranged on the base plate 26, a vibrating screen 3 arranged at the discharge end of the drum 2, and a vibrating plate 4 arranged below the vibrating screen 3; the drum 2 One end is provided with a material inlet 21, and the other end is provided with a material outlet 22. The vibrating screen 3 is located under one end of the drum 2 outlet 22; the sand and the pin shaft that needs to be rounded are added to the drum 2 together, and the drum 2 During the rolling process, the sand is driven to fillet the pin shaft. After processing, the sand and the pin shaft are added to the vibrating screen 3 together. After being screened by the vibrating screen 3, the pin shaft is sent out from the discharge end of the vibrating screen 3. , the sand is sent out fro...

Embodiment 2

[0051] Embodiment two: a kind of production technology of chain mainly comprises the following steps:

[0052] (1) Chain piece processing: a. Cutting: use a punch to cut the chain piece; b. Vacuum quenching: use propane and kerosene as fuel to heat the chain piece to 850-880°C, and then keep it warm for 45-80 minutes; after the heat preservation, use oil as the medium to quench the chain piece; c. Cleaning and degreasing: use water to clean the chain after quenching, and clean the oil stains on the surface of the chain; d. Tempering: heat the chain to 280-320°C, keep it warm for 30-40 minutes, then take it out and cool it to room temperature with air;

[0053] (2) Roller processing: a. Cutting: using roller chain coiler to produce shaft sleeve; b. Quenching: Use propane and methanol as fuel to heat the roller to 800°C, and then keep it warm for 45 minutes; after the keep warm, use water as the medium to quench the chain piece; c. Tempering: heat the roller to 260°C, then ...

Embodiment 3

[0059] Embodiment three: a kind of production technology of chain, mainly comprises the following steps:

[0060] (1) Chain piece processing: a. Cutting: use a punch to cut the chain piece; b. Vacuum quenching: use propane and kerosene as fuel to heat the chain piece to 860°C, and then keep it warm for 60 minutes; after the heat preservation, use oil as the medium to quench the chain piece; c. Cleaning and degreasing: use water to clean the chain after quenching, and clean the oil stains on the surface of the chain; d. Tempering: heat the chain to 300°C, keep it warm for 35 minutes, then take it out and cool it to room temperature with air;

[0061] (2) Roller processing: a. Cutting: using roller chain coiler to produce shaft sleeve; b. Quenching: Use propane and methanol as fuel to heat the roller to 810°C, and then keep it warm for 45 minutes; after the keep warm, use water as the medium to quench the chain piece; c. Tempering: Heat the roller to 270°C, keep it warm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com