Anti-blockage crusher

A crusher and anti-jamming technology, which is applied in the field of mechanical equipment, can solve the problems of crusher jamming, difficult crushing, and low crushing efficiency, and achieve the effect of preventing crusher jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

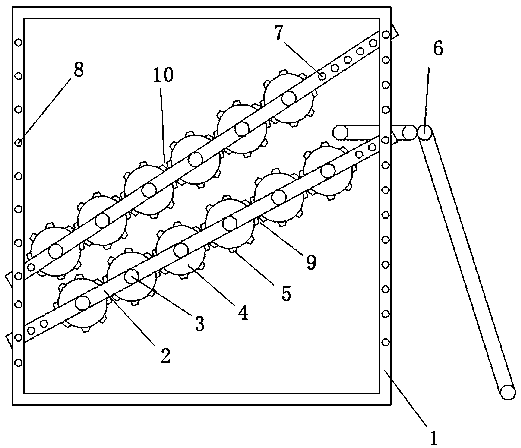

[0027] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this embodiment discloses an anti-jamming crusher, this embodiment includes:

[0028] An anti-jamming crusher, comprising a bracket 1, on which a crushing roller group 1 9 and a crushing roller group 2 10 are arranged, and the crushing roller group 1 9 and the crushing roller group 2 10 are arranged side by side by a plurality of crushing rollers 4, Crushing roller group 2 10 is set above crushing roller group 1 9; crushing roller group 1 9 and crushing roller group 2 10 are arranged obliquely, and the distance between crushing roller group 1 9 and crushing roller group 2 10 is large at one end and small at the other end. One end is the feed end.

[0029] The crushing roller group one 9 and the crushing roller group two 10 both include two fixed rods 2 arranged side by side, the crushing roller 4 is arranged between the two fixed rods 2 , and the crushing roller 4 is connected...

Embodiment 2

[0036] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this embodiment discloses an anti-jamming crusher, this embodiment includes:

[0037] An anti-jamming crusher, comprising a bracket 1, on which a crushing roller group 1 9 and a crushing roller group 2 10 are arranged, and the crushing roller group 1 9 and the crushing roller group 2 10 are arranged side by side by a plurality of crushing rollers 4, Crushing roller group 2 10 is set above crushing roller group 1 9; crushing roller group 1 9 and crushing roller group 2 10 are arranged obliquely, and the distance between crushing roller group 1 9 and crushing roller group 2 10 is large at one end and small at the other end. One end is the feed end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com