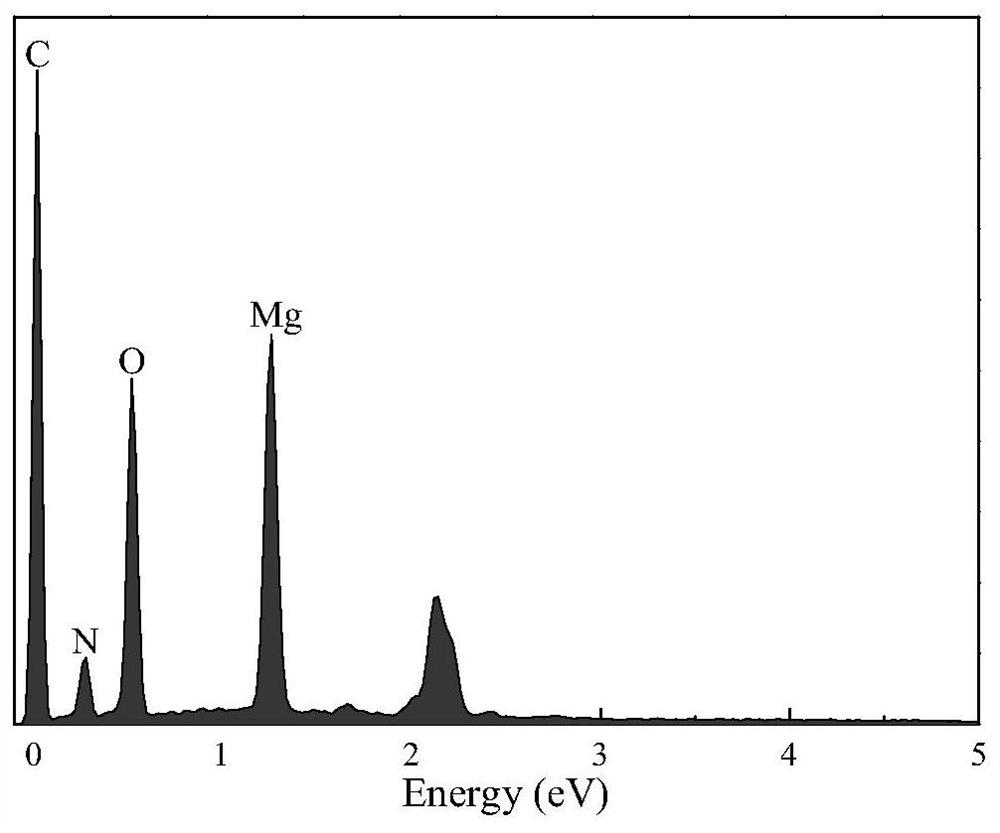

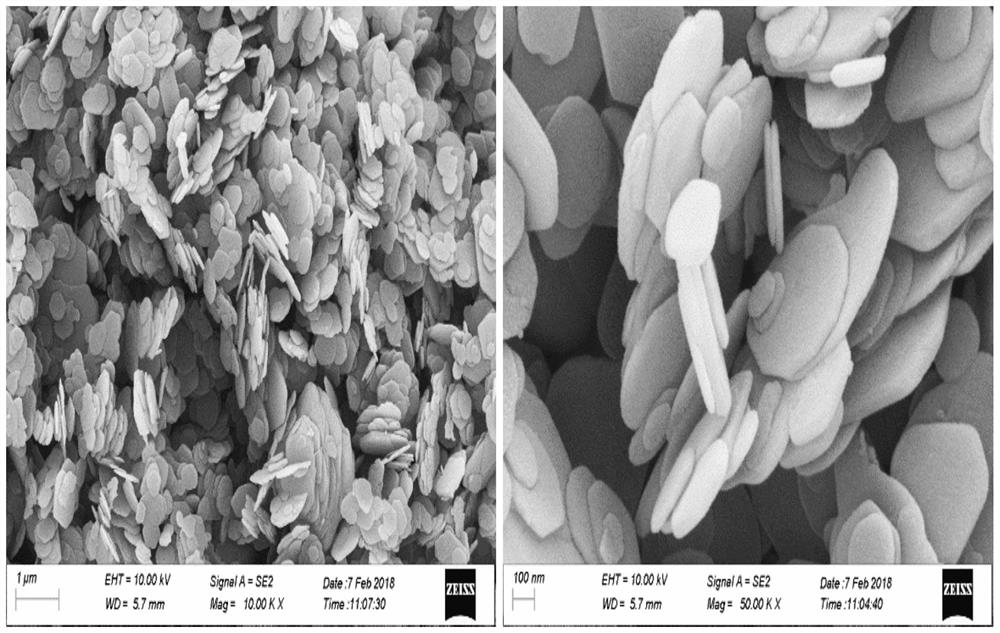

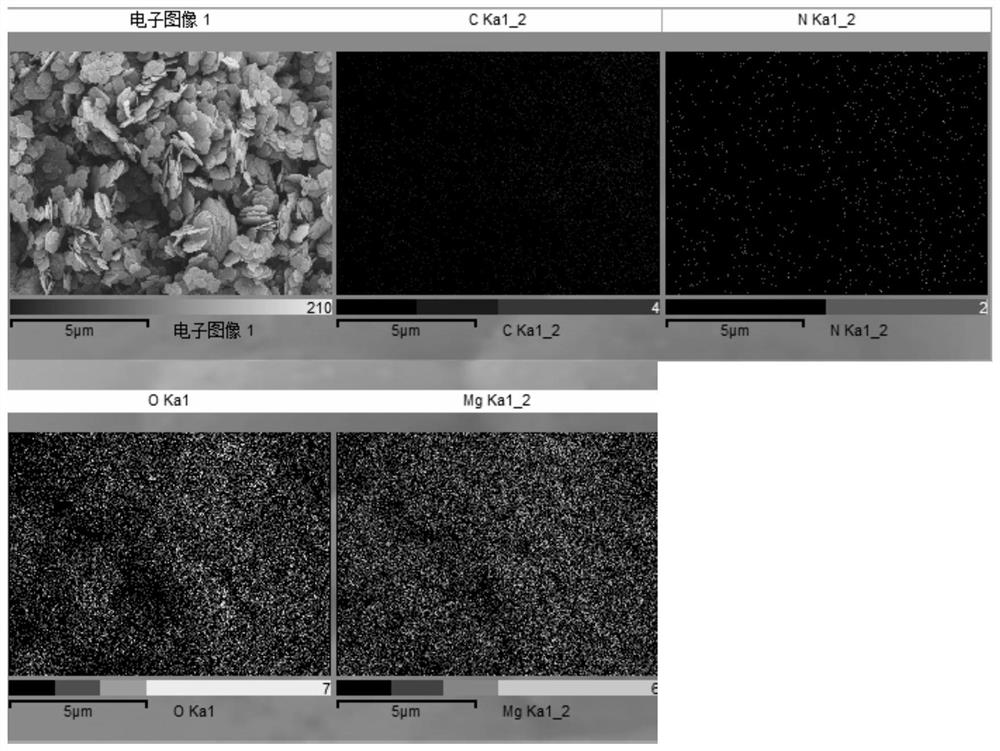

Preparation method and application of a nitrogen-doped carbon-magnesium composite nanosheet

A technology of nitrogen doping and nanosheets, which is applied in chemical instruments and methods, catalyst activation/preparation, alkali metal compounds, etc., can solve the problems of photocatalytic activity that needs to be further improved, and achieve the solution of difficult collection, simple operation, and improved The effect of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing nitrogen-doped carbon-magnesium composite nanosheets, comprising the following six steps:

[0034] 1) Weighing a certain quality of magnesium chloride hexahydrate and surfactant 1 into ethanol aqueous solution 1 and stirring at constant temperature to form a uniform magnesium salt solution;

[0035] 2) Ammonia water with an equal stoichiometric ratio is added to the above-mentioned magnesium salt solution and continuously stirred to form a magnesium hydroxide slurry;

[0036] 3) Put the slurry into a high-temperature reactor for reaction, and after the reaction is completed, the liquid is cooled naturally, and the supernatant is removed, and washed twice with deionized water and ethanol respectively;

[0037] 4) Prepare a slurry solution with ethanol aqueous solution 2, add cyanamide and surfactant 2 according to the formula ratio and stir at constant temperature;

[0038] 5) After stirring evenly, put it into a high-pressu...

Embodiment 1

[0055] Weigh 2.6g of magnesium chloride hexahydrate and 1.0g of polyvinylpyrrolidone (Mw=58000) into 50mL of 20% ethanol solution, and stir at a temperature of 25°C and a stirring speed of 400r / min for 20min to form a magnesium salt solution. 3mL ammonia solution (analytical grade, NH 3 ·H 2 O content 15%-28%) was added to the magnesium salt solution at a constant speed, and stirred at a constant temperature for 60 minutes at a temperature of 25° C. and a stirring speed of 450 r / min to form a magnesium hydroxide slurry. Put the slurry into a high-temperature reactor and react at 170°C for 10 hours. After natural cooling, remove the supernatant, and wash twice with deionized water and ethanol respectively; For the slurry solution, add 12mL cyanamide and 1.5g polyvinylpyrrolidone (Mw=58000) to the above slurry solution, and stir at a temperature of 25°C and a stirring speed of 500r / min for 120min to form a magnesium amine slurry. Put the slurry into an autoclave and react at 2...

Embodiment 2

[0057] Weigh 5.1g of magnesium chloride hexahydrate and 1.0g of polyvinylpyrrolidone (Mw=58000) into 80mL of 50% ethanol solution, and stir at a constant temperature of 25°C and a stirring speed of 600r / min for 30min to form a magnesium salt solution. 5mL ammonia solution (analytical grade, NH 3 ·H 2 O content 15%-28%) was added to the magnesium salt solution at a constant speed, and stirred at a constant temperature for 80 minutes at a temperature of 25° C. and a stirring speed of 600 r / min to form a magnesium hydroxide slurry. Put the slurry into a high-temperature reactor and react at 170°C for 10 hours. After natural cooling, remove the supernatant, and wash twice with deionized water and ethanol; use 120mL of 50% ethanol solution to prepare 8g / L For the slurry solution, add 8 mL of cyanamide and 1.5 g of polyvinylpyrrolidone (Mw=58000) to the above slurry solution, and stir at a temperature of 25° C. and a stirring speed of 500 r / min for 120 min to form a magnesium amine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com