Tryptophan TVR (Thermal Vapour Recompressor) evaporation, concentration and crystallization system, and method for concentrating and crystallizing by using system

An evaporation concentration and crystallization system technology, applied in the direction of evaporation separation crystallization, multi-effect evaporation, solution crystallization, etc., can solve the problems of insufficient secondary steam utilization, product quality decline, unqualified content, etc., to achieve maximum utilization of steam, improve Effects of crystallization quality and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

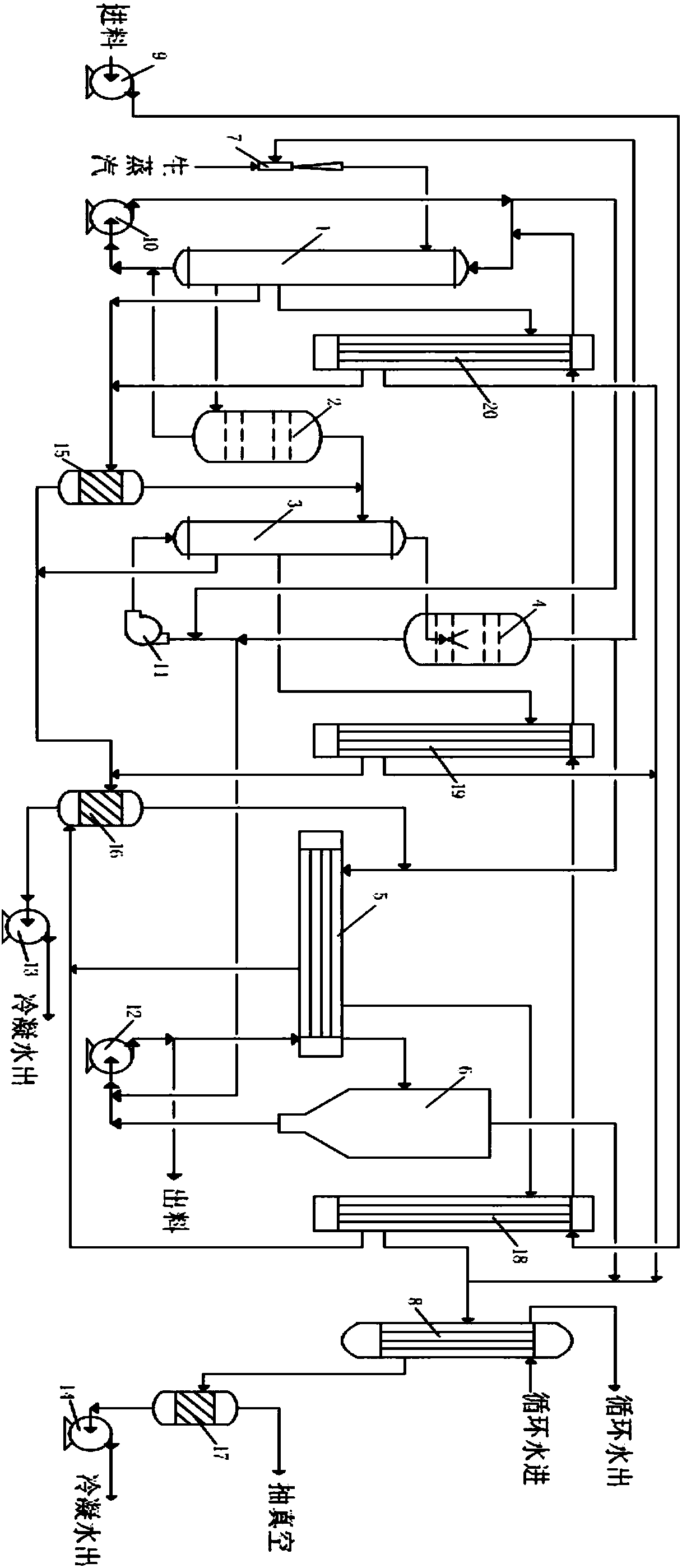

[0034] Such as figure 1 As shown, a tryptophan TVR evaporation concentration crystallization system includes a first-effect evaporator 1, a first-effect separator 2, a second-effect evaporator 3, a second-effect separator 4, a crystallization heater 5, an evaporation crystallizer 6, a steam Jet pump 7, surface condenser 8, feed pump 9, first-effect circulation pump 10, second-effect circulation pump 11, circulation discharge pump 12, condensate pump 13, vacuum condensate pump 14, first-stage condensate tank 15, second-stage Condensed water tank 16, vacuum condensed water tank 17, primary heat exchanger 18, secondary heat exchanger 19, and tertiary heat exchanger 20;

[0035] The one-effect evaporator 1 forms a circulation passage with the one-effect circulating pump 10 through a pipeline, the one-effect evaporator 1 communicates with the one-effect separator 2 through a pipeline, and the one-effect separator 2 communicates with the second-effect evaporator 3;

[0036] Describ...

Embodiment 2

[0046] Embodiment 2 Concrete process is as follows:

[0047] The material is transported to the primary heat exchanger 18, the secondary heat exchanger 19, and the tertiary heat exchanger 20 in sequence through the feed pump 9, and performs heat exchange with the steam in the heat exchanger respectively to increase the temperature of the material. The material enters the upper feed port of the first-effect evaporator 1 and undergoes falling film evaporation. The material is transported from the lower outlet of the first-effect evaporator 1 to the inlet of the first-effect circulating pump 10 through pipelines, and is transported from the outlet of the first-effect circulating pump 10 to the The feeding port above the first-effect evaporator 1 performs circulation evaporation.

[0048] The material is transported through the outlet pipeline of the first-effect circulating pump 10 to the inlet of the second-effect circulating pump 11, and the second-effect circulating pump 11 tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com