Folium mori moxibustion formula and use thereof

A technology of moxibustion and formula, which is applied in the direction of medical formula, medical preparations containing active ingredients, and medical raw materials derived from gymnosperm subphylum, etc. It can solve the problems of inability to exert therapeutic effect, unsatisfactory therapeutic effect, low temperature when burning, etc. problems, to achieve the effect of improving autoimmunity, regulating human metabolism, and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

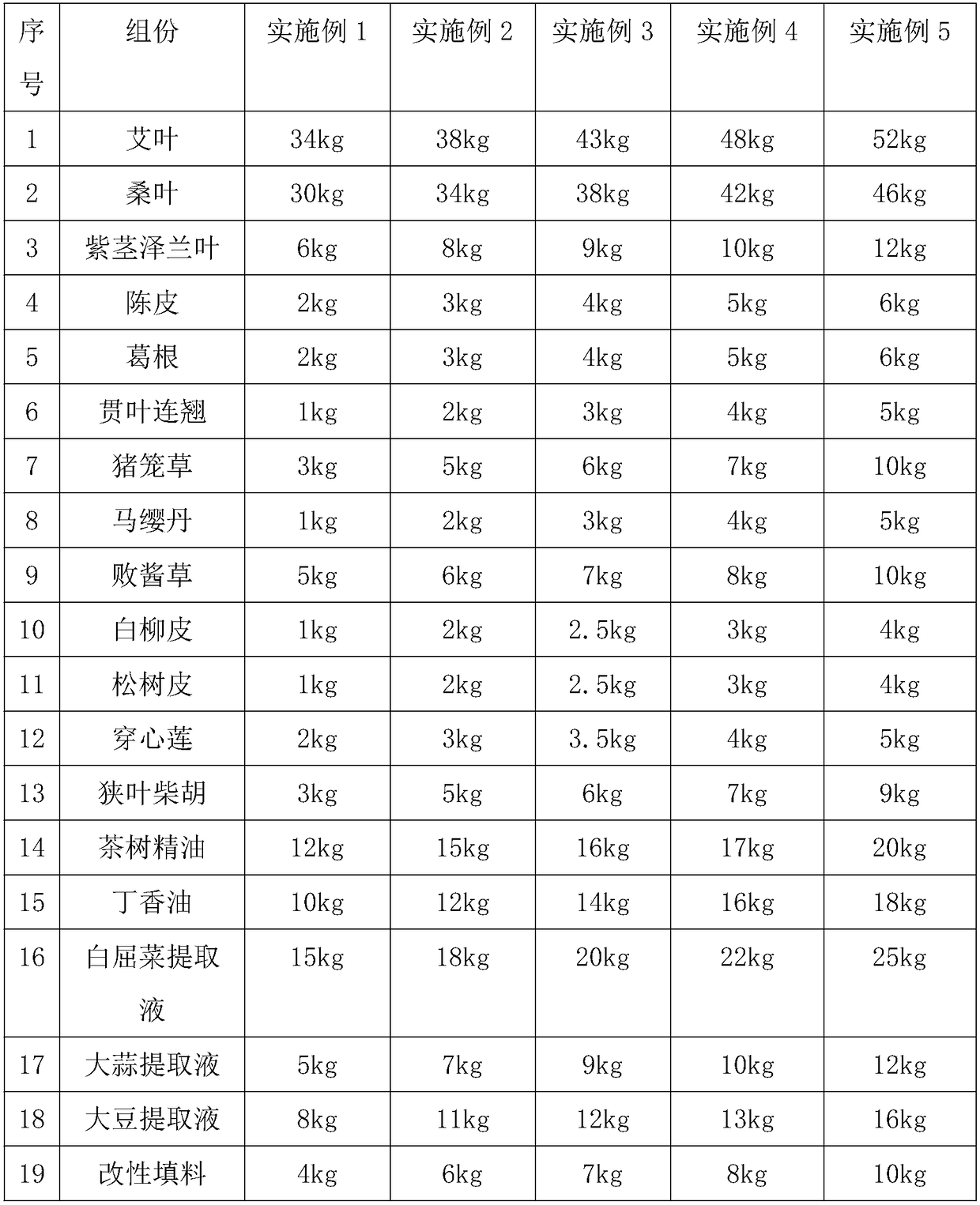

Examples

Embodiment 1

[0029] Preparation of modified filler: Take 4kg of stove core soil and roast for 50min at a roasting temperature of 320°C, take it out after air-cooling to 70°C with the furnace, grind it to a 60-mesh sieve, add 6% diatomite mass of glyceryl monostearate and mix well Instantly.

[0030] Preparation of celandine extract: get 30kg of celandine and add ethanol with an alcohol concentration of 2 times the quality of celandine is 95% ethanol, heat and reflux for 2h, filter to obtain a filter residue, add the filter residue to 2 times the quality of the filter residue Ethanol with an alcohol concentration of 95%, heated to reflux for 1 hour, filtered to remove impurities, combined filtrates, and obtained after removing ethanol.

[0031] Preparation of garlic extract: Take 10kg of garlic and grind it into garlic puree, add 95% ethanol and ultrasonically disperse it for 15 minutes, the ratio of solid to liquid is 1:8, after standing for 2 hours, centrifuge at a high speed of 2500r / min...

Embodiment 2

[0038] Preparation of modified filler: take 6 kg of stove core soil and roast for 55 minutes at a temperature of 330°C, take it out with air cooling to 75°C, grind to a 70-mesh sieve, add 7% diatomite mass of glyceryl monostearate and mix well Instantly.

[0039] Preparation of celandine extract: get 35kg of celandine and add ethanol with an alcohol concentration of 95% relative to the mass of celandine, heat and reflux for 2.5h, filter to obtain a filter residue, and add the filter residue to 3 times the mass of the filter residue The alcohol concentration is 95% ethanol, heated to reflux for 1.5h, filtered to remove impurities, combined filtrates, and obtained after removing ethanol.

[0040] Preparation of garlic extract: take 15kg of garlic and grind it into garlic paste, add 95% ethanol for ultrasonic dispersion treatment for 20min, the ratio of solid to liquid is 1:9, let it stand for 2.5h, then centrifuge at a high speed at 2500r / min for 22min, discard the upper The supe...

Embodiment 3

[0047] Preparation of modified filler: take 7 kg of stove core soil and roast for 55 minutes at a roasting temperature of 330°C, take it out after air cooling to 75°C with the furnace, grind to a 70-mesh sieve, add 7% diatomaceous earth mass of glyceryl monostearate and mix well Instantly.

[0048] Preparation of celandine extract: take 40kg celandine and add ethanol with an alcohol concentration 3 times that of celandine mass, which is 95% ethanol, heat and reflux for 2.5h, filter to obtain filter residue, and add filter residue 3 times relative to the quality of filter residue The alcohol concentration is 95% ethanol, heated to reflux for 1.5h, filtered to remove impurities, combined filtrates, and obtained after removing ethanol.

[0049] Preparation of garlic extract: Grind 20kg of garlic into garlic paste, add 95% ethanol for ultrasonic dispersion treatment for 20min, the ratio of solid to liquid is 1:10, let it stand for 2.5h, then centrifuge at a high speed of 2500r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com