Method for preparing blood lipid reducing ingredient in heracleum modlendouffii

A hypolipidemic and high shear technology, applied in the functions of food ingredients, food ingredients, food ultrasonic treatment, etc., can solve the problems of low utilization, insufficient popularity, and insufficient related research, so as to improve utilization and improve efficiency. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Raw material processing: Wash and drain the fresh old celery, mix it with distilled water at a ratio of 1:2, beat it and refrigerate it for later use.

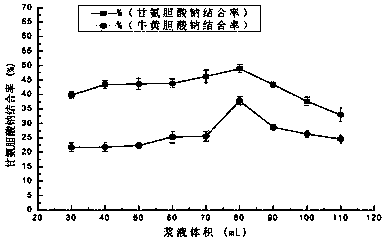

[0041] 2. High-shear treatment: Mix the above-mentioned homogenate with absolute ethanol, keep the shear rate at 10000r / min, the volume of the slurry is 80mL, and the shear time is 1min, and carry out high-shear treatment on the mixed solution to obtain extract.

[0042] 3. Ultrasonic-assisted extraction: mix the obtained extract with absolute ethanol at a ratio of 1:10, keep the ultrasonic power at 50%, the ultrasonic time for 40min, and the ultrasonic temperature at 50°C. Ultrasonic-assisted extraction was performed on the liquid to obtain the extract.

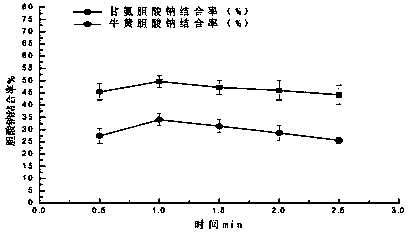

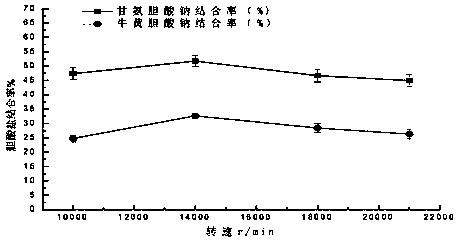

[0043] The functional component detection of the extract obtained in step 3 shows that the flavonoid content is 0.988 mg / g, and the polyphenol content is 1.723 mg / g; the result of the in vitro cholate binding experiment is: sodium glycocholate binding The rate is...

Embodiment 2

[0045] 1. Raw material processing: Wash and drain the fresh old celery, mix it with distilled water at a ratio of 1:2, beat it and refrigerate it for later use.

[0046] 2. High-shear treatment: Mix the above-mentioned homogenate with absolute ethanol, keep the shear rate at 14000r / min, the slurry volume is 80mL, and the shear time is 1min, and carry out high-shear treatment on the mixed solution to obtain extract.

[0047] 3. Ultrasonic-assisted extraction: Mix the obtained extract with absolute ethanol at a ratio of 1:10, keep the ultrasonic power at 50%, the ultrasonic time for 40min, and the ultrasonic temperature at 50°C for the extraction in step 2. Ultrasonic-assisted extraction was performed on the liquid to obtain the extract.

[0048] The functional component detection of the extract obtained in step 3 shows that the flavonoid content is 0.774 mg / g, and the polyphenol content is 1.324 mg / g; the result of the in vitro cholate binding experiment is: sodium glycocholat...

Embodiment 3

[0050] 1. Raw material processing: Wash and drain the fresh old celery, mix it with distilled water at a ratio of 1:2, beat it and refrigerate it for later use.

[0051] 2. High-shear treatment: Mix the above-mentioned homogenate with absolute ethanol, keep the shear rate at 14000r / min, the slurry volume is 80mL, and the shear time is 1min, and carry out high-shear treatment on the mixed solution to obtain extract.

[0052] 3. Ultrasonic-assisted extraction: mix the obtained extract with absolute ethanol in a ratio of 1:8 to keep the ultrasonic power at 50%, the ultrasonic time for 80min, and the ultrasonic temperature at 50°C for the extract in step 2 Ultrasonic-assisted extraction is carried out to obtain an extract.

[0053] The functional component detection of the extract obtained in step 3 shows that the flavonoid content is 0.667 mg / g, and the polyphenol content is 2.238 mg / g; the result of the in vitro cholate binding experiment is: sodium glycocholate binding The ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com