High-solubility soybean peptide as well as preparation technology and application thereof

A soybean polypeptide, high solubility technology, used in applications, protein food processing, vegetable protein processing and other directions, can solve the problems of limited solubility, reduced protein and polypeptide content in products, and easy to produce precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

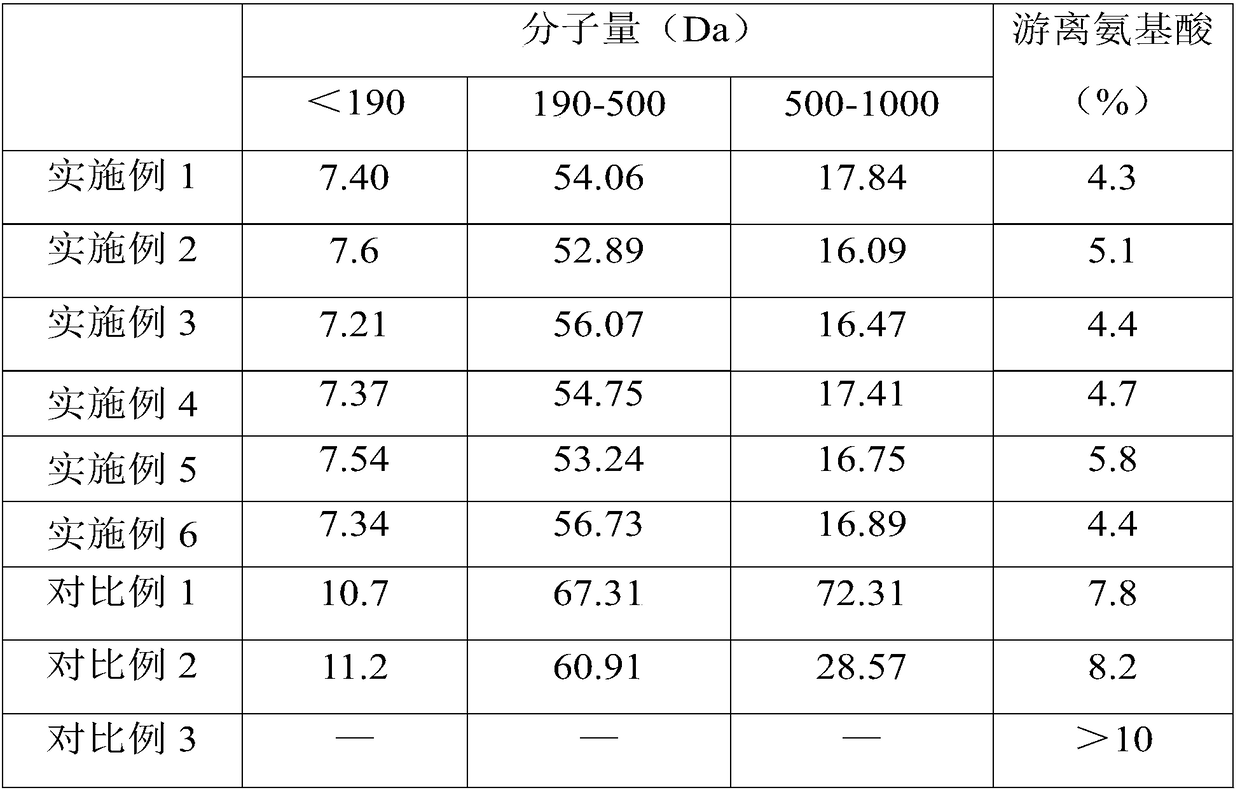

Examples

Embodiment 1

[0044] This embodiment provides a highly soluble soybean polypeptide, which is prepared by the following preparation process:

[0045] Weigh 1 kg of soybean protein isolate and 15 kg of distilled water, mix and stir evenly, and the rotating speed of mixing and stirring is 60 r / min to prepare soybean protein isolate slurry.

[0046] Raise the temperature of soybean protein isolate slurry to 50°C, add 0.015kg of alkaline protease under natural pH conditions for the first enzymatic hydrolysis for 2 hours; then add 0.015kg of neutral protease for the second enzymatic hydrolysis for 3 hours; then add citric acid Adjust the pH to 5.4-6.2, add 0.003 kg of acidic protease, and perform the third enzymatic hydrolysis for 1 hour to obtain an enzymatic hydrolysis solution.

[0047] Heat the enzymolysis solution to 95°C and keep it for 18 minutes to inactivate the enzyme activity.

[0048] Cool the enzymolysis solution after inactivation to 65°C, add 4% of its mass of activated carbon, st...

Embodiment 2

[0050] This embodiment provides a highly soluble soybean polypeptide, which is prepared by the following preparation process:

[0051] Weigh 1kg soybean protein isolate and 12kg distilled water, mix and stir evenly, the rotating speed of mixing and stirring is 70r / min, make soybean protein isolate slurry.

[0052] Raise the temperature of soybean protein isolate slurry to 55°C, add 0.03kg of alkaline protease under natural pH conditions for the first enzymolysis for 0.3h; then add 0.03kg of neutral protease for the second enzymolysis for 2h; then add apples Adjust the pH to 5.4-6.2 with acid, add 0.005 kg of acidic protease, and carry out the third enzymolysis for 0.5-2 hours to obtain an enzymolysis solution.

[0053] Heat the enzymatic solution to 100°C and keep it for 15 minutes to inactivate the enzyme.

[0054] Cool the enzymolysis solution after inactivation to 70°C, filter the enzymolysis solution through a roll-type ultrafiltration membrane purification system with a ...

Embodiment 3

[0056] This embodiment provides a highly soluble soybean polypeptide, which is prepared by the following preparation process:

[0057] Weigh 1kg soybean protein isolate and 18kg distilled water, mix and stir evenly, the rotating speed of mixing and stirring is 40r / min, make soybean protein isolate slurry.

[0058] Raise the temperature of soybean protein isolate slurry to 50°C, add 0.008kg alkaline protease under natural pH conditions, and carry out the first enzymatic hydrolysis for 1 hour; then add 0.008kg neutral protease, and carry out the second enzymatic hydrolysis for 5 hours; then add acetic acid to adjust The pH is 5.4-6.2, add 0.001kg of acidic protease, carry out the third enzymolysis for 2 hours, and obtain the enzymolysis solution.

[0059] Heat the enzymolysis solution to 90°C and keep it for 20 minutes to inactivate the enzyme activity;

[0060] Cool the enzymatic hydrolysis solution after inactivation to 60°C, add 6% of its mass activated carbon, stir for 25 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com