Chip-type fixed resistor and production method thereof

A technology of fixed resistors and manufacturing methods, applied in the direction of resistor manufacturing, resistors, resistor components, etc., can solve problems such as incapable IC circuit packaging, unfavorable circuit space costs, and affecting working circuits, so as to achieve good market development potential and save energy. The effect of low circuit space cost and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

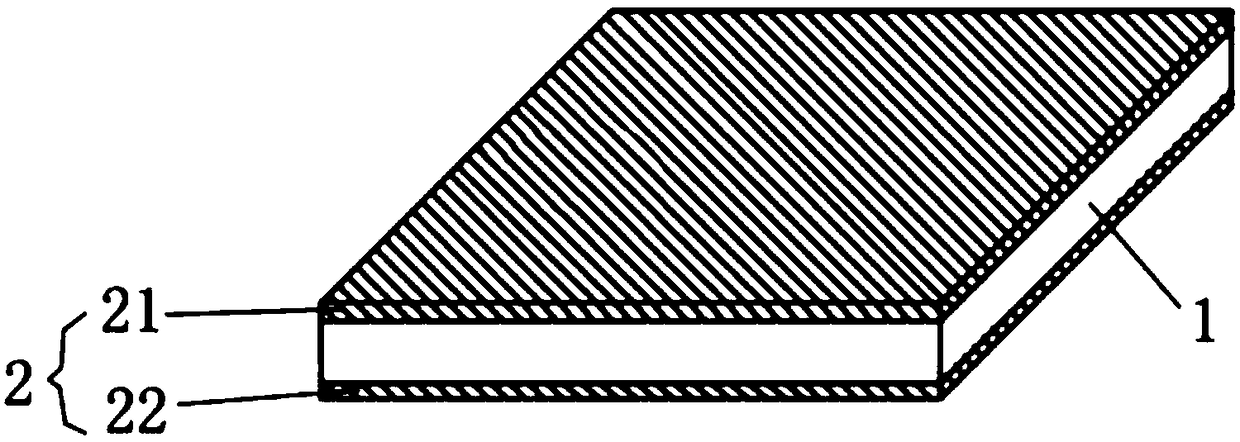

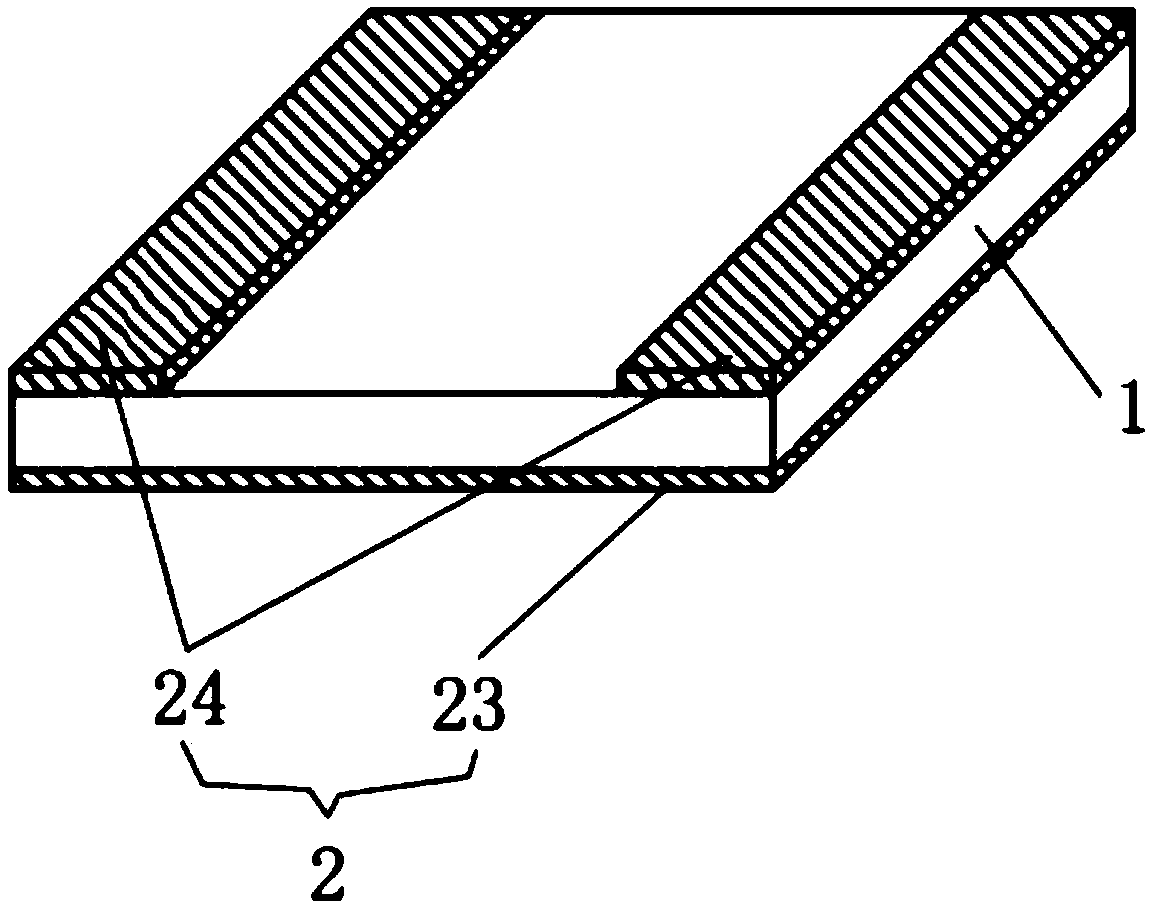

[0042] see figure 1 and figure 2 , figure 1 It is a structural diagram of the first embodiment of the chip type fixed resistor of the present invention, figure 2 It is a structural diagram of the second embodiment of the chip type fixed resistor of the present invention.

[0043] The chip type fixed resistor provided by the present invention includes a substrate 1 and a metal electrode 2 .

[0044] The substrate 1 is a rectangular sheet structure, and its two surfaces are respectively the front and the back.

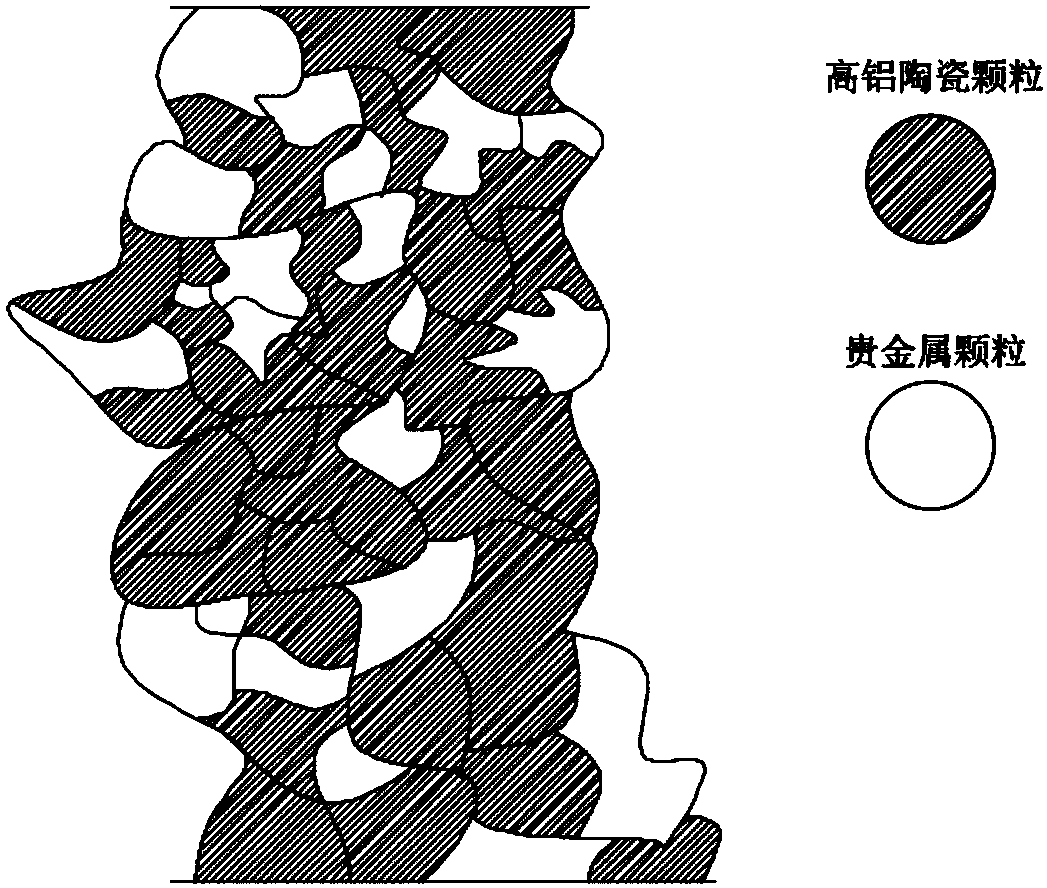

[0045] The substrate 1 is formed by mixing and sintering three kinds of powders: high alumina ceramic powder, precious metal powder and glass powder. In terms of mass percentage, the high alumina ceramic powder accounts for 60-99% of the mixed powder, the precious metal powder accounts for 0.5-30% of the mixed powder, and the glass powder accounts for 0.5-10% of the mixed powder.

[0046] Such as image 3 As shown, the noble metal particles formed after sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com