Pump cover capable of installing safety valve

A safety valve and pump cover technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc. Volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

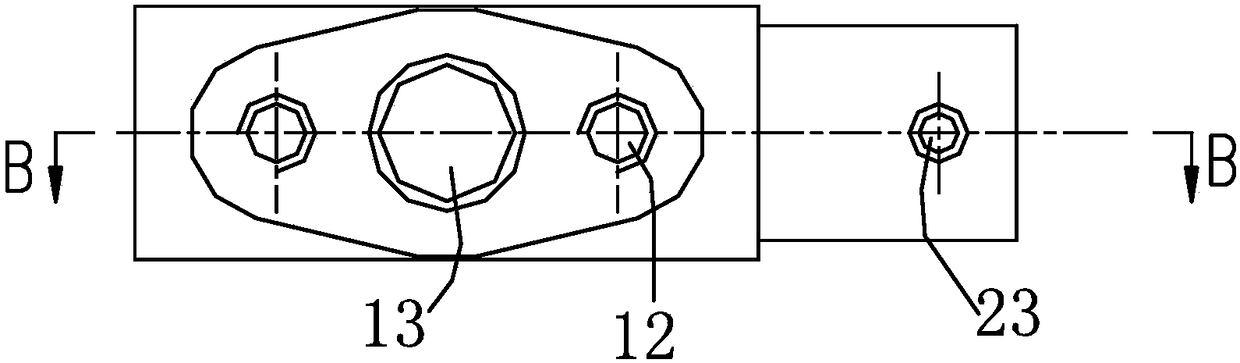

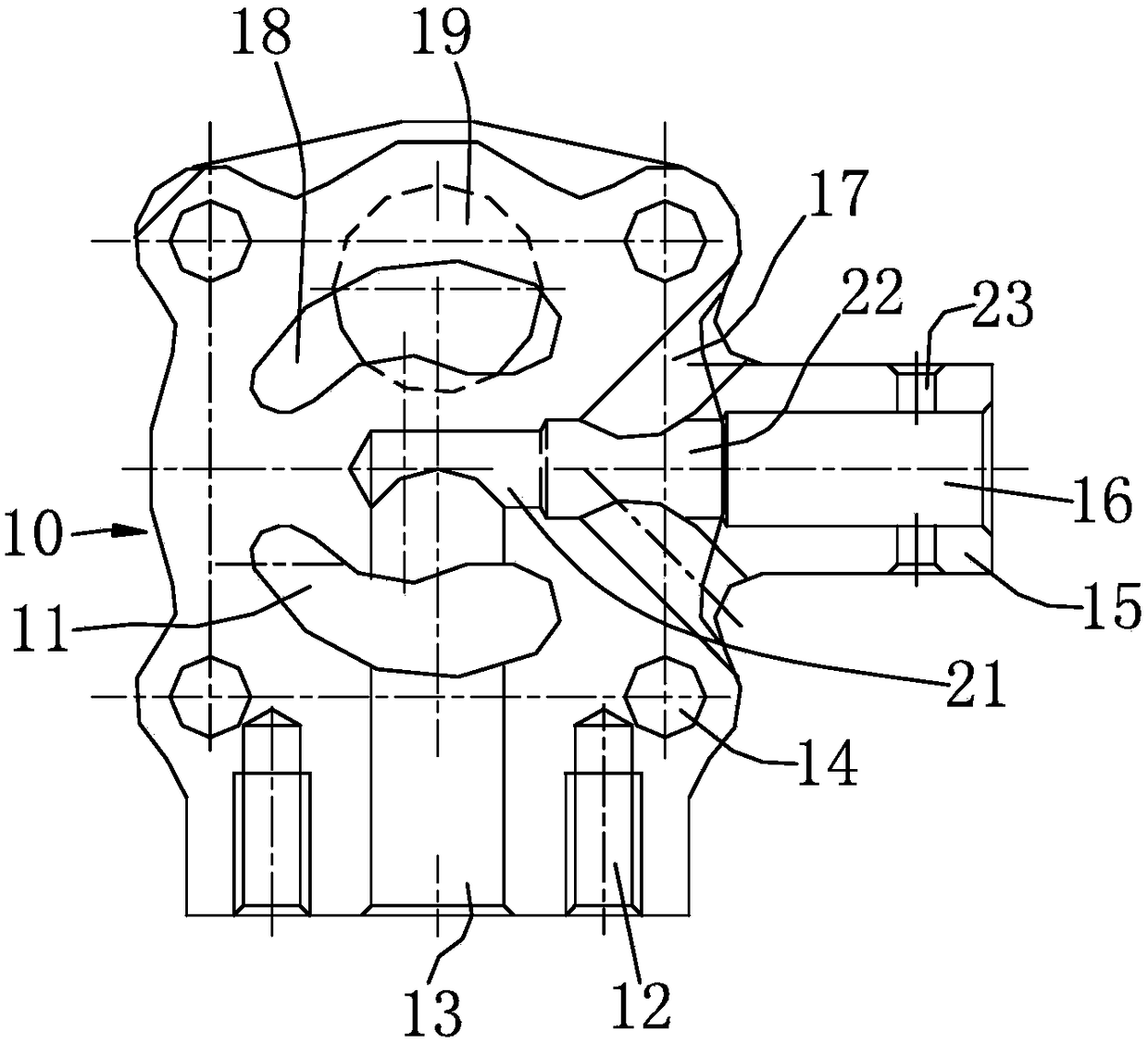

[0013] refer to figure 1 and figure 2 , a pump cover capable of installing a safety valve, the pump cover includes a flat body 10, the body includes an inner surface for covering on the pump body, the body is provided with a shaft hole 19, an oil outlet 13. The shaft hole 19 runs through the body 10, and an oil inlet chamber 18 and an oil outlet chamber 11 are arranged on the inner surface of the body, and the oil inlet chamber 18 and the oil outlet chamber 11 are arranged oppositely; A safety valve body 15 is arranged on the side, and the safety valve body is integrally formed with the body. A spring mounting hole 16 is opened in the safety valve body. One end of the spring mounting hole extends out of the safety valve body, and the other end of the spring mounting hole faces into the body. Extend and continuously form the valve ball section 22 and the inlet section 21, the spring installation hole 16, the valve ball section 22 and the inlet section 21 form a cavity for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com