Overflow dam front hydraulic automatic desilting system and construction method

A hydraulic automatic and construction method technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problems of poor silt reduction effect, soil erosion, and high cost of siltation, and achieve good silt reduction effect, convenient maintenance, and operation. Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Example.

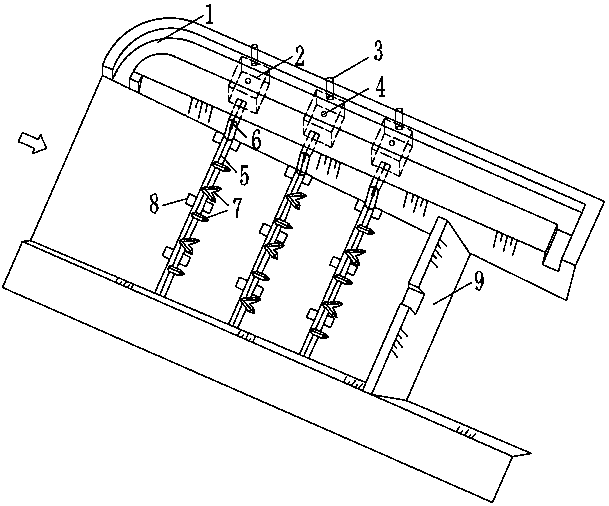

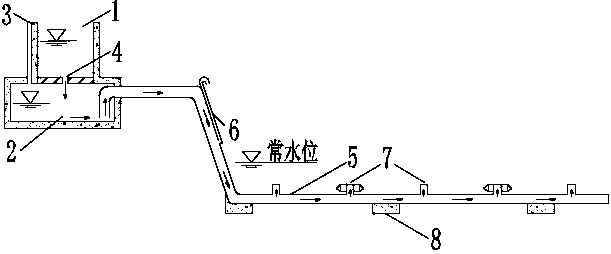

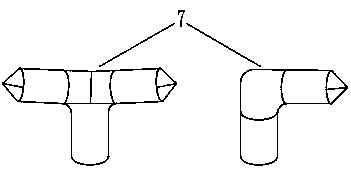

[0026] The invention discloses a hydraulic automatic silt reduction system and a construction method in front of a rolling dam. The silt reduction system includes a bank diversion channel 1 , a sump 2 , a sand washing pipe 5 and a fixed pier 8 . The sump 2 is located at the bottom of the water diversion canal 1, and the vent hole 3 (to balance the pressure of the sump 2 and the outside atmosphere) and the water inlet 4 are arranged on the top of the sump, and the sand washing pipe 5 is connected to the side of the sump. The inlet section of the sand washing pipe 5 is an inverted U-shaped pipe, the flat pressure pipe 6 is arranged on the slope section, and the sand washing nozzle 7 is arranged on the pipe body of the river section fixed by the fixed pier 8 .

[0027] Further, in the diversion canal 1, the head of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com