Method for preparing soil conditioner from gelatin solid waste

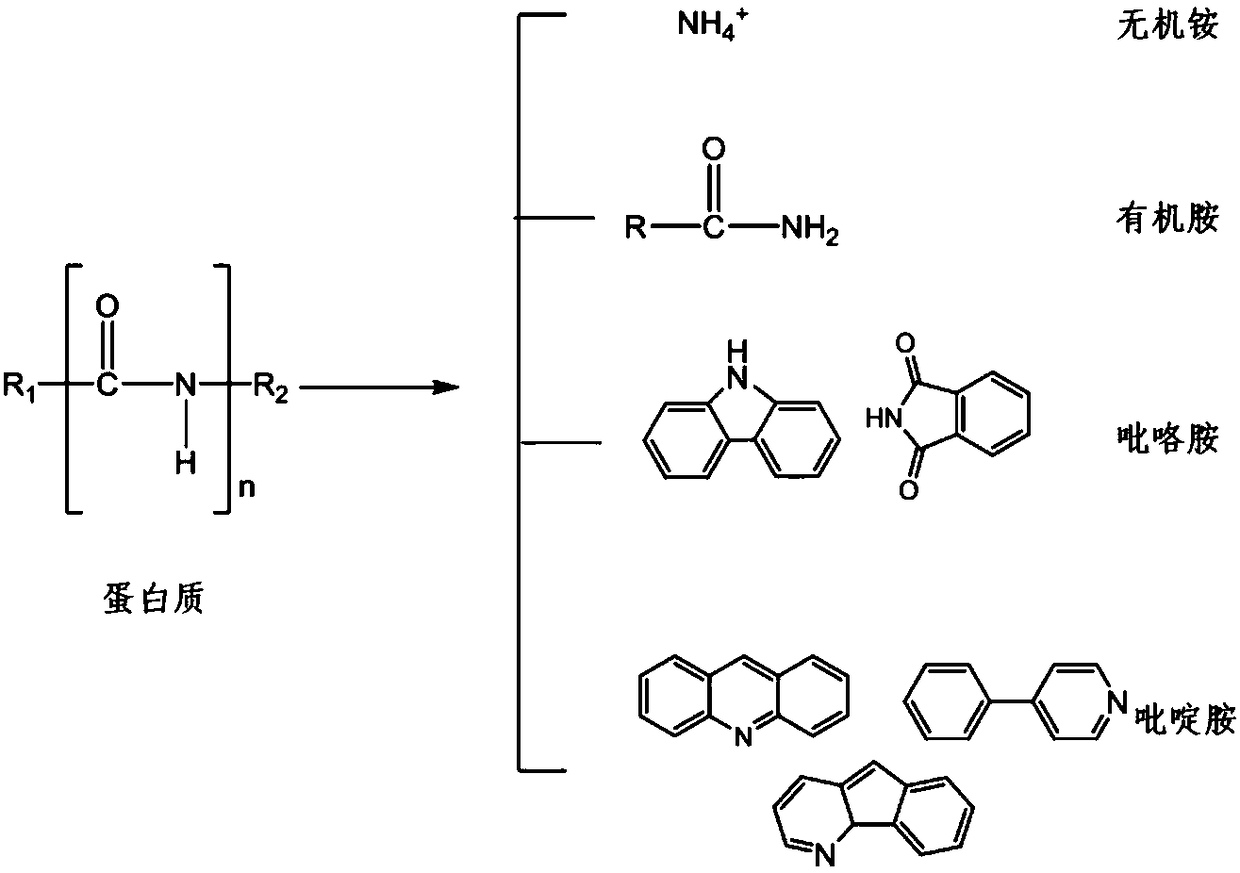

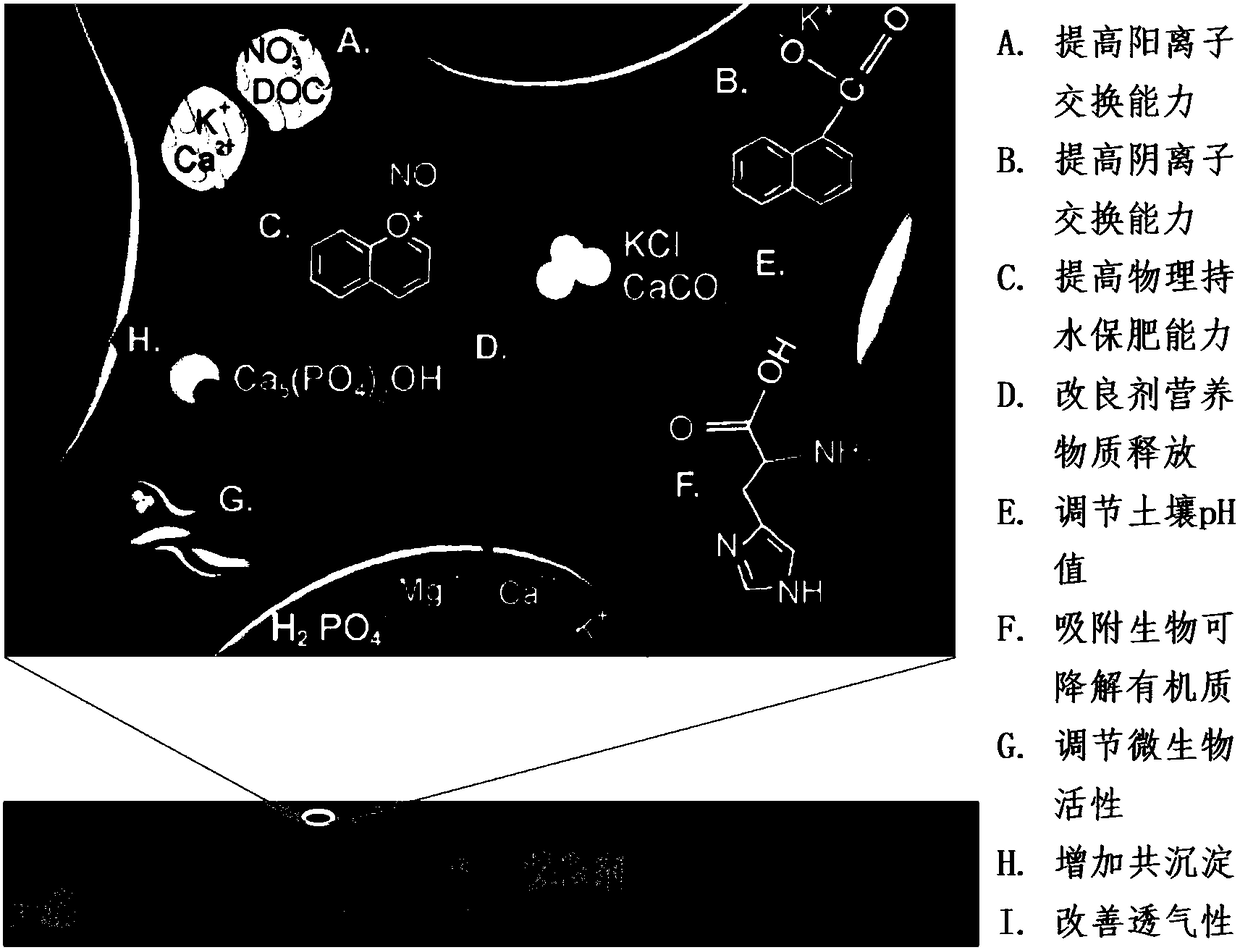

A soil conditioner and gelatin technology, which is applied in the field of solid waste treatment and disposal in the gelatin industry, can solve the problems of high harm to the atmospheric environment and human health, and easy decay and deterioration during storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

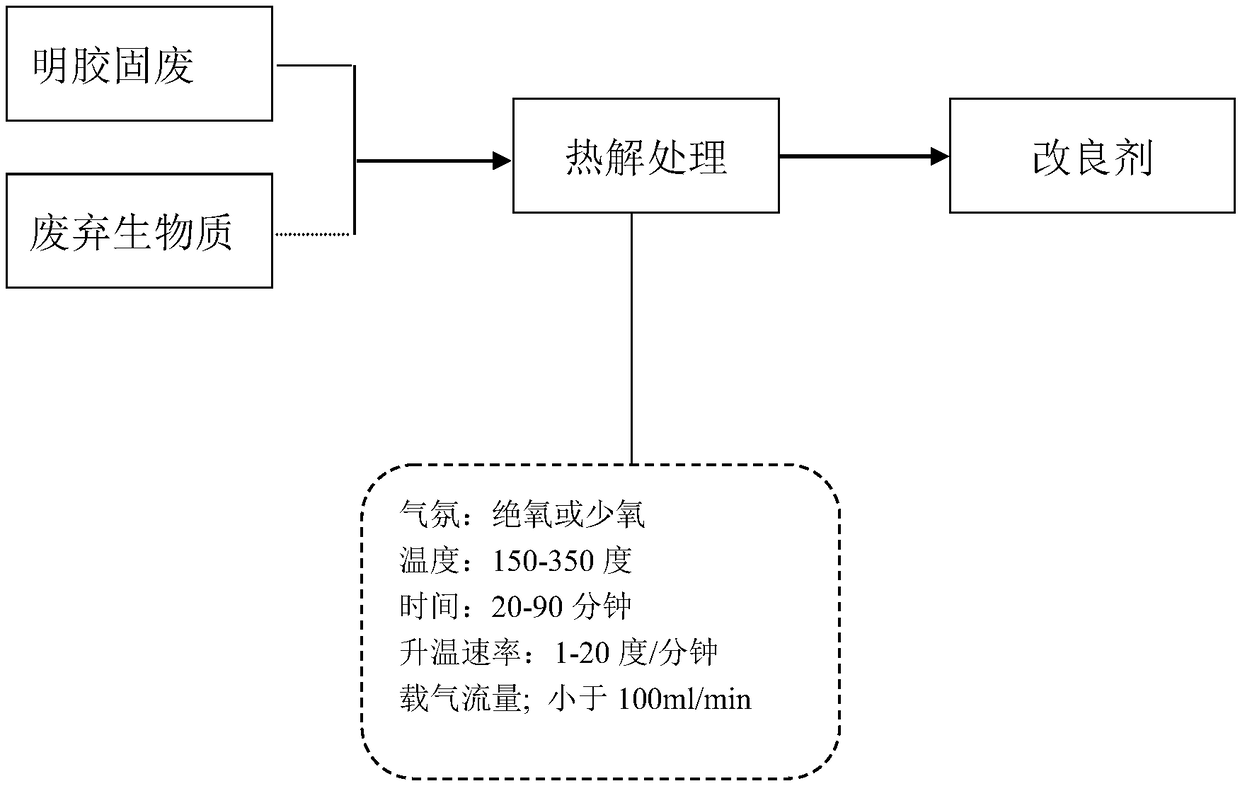

Method used

Image

Examples

Embodiment 1

[0027] 1. Material preparation

[0028] The gelatin solid waste was carbonized under the following conditions: carbonization temperature 250 degrees, carbonization time 45min, carrier gas nitrogen flow rate 40ml / min. The obtained carbonized gelatin solid waste is passed through a 0.5mm sieve for later use.

[0029] 2. Soil improvement experiment design

[0030] Two dosages of improvers (20t / hm2, 40t / hm 2 ) was evenly sprinkled on the surface of the soil (soil properties: TOC 11.76g / kg; TN 0.68g / kg; TP 0.39g / kg; TK 17.63g / kg, pH 7.23) on April 6, 2015, and then thoroughly mixed ( The depth is about 15cm). Randomized block design was adopted, with 4 repetitions, each plot area was 1.5x 1.5m, and there was an isolation zone of about 0.5m between the plots. The planted crops are wheat and corn rotation (April 22, 2015-April 10, 2016), and the management measures are the same except for the different dosage of improvers. After harvesting on April 6, 2016, random samples were t...

Embodiment 2

[0036] 1. Material preparation

[0037] Fully mix gelatin solid waste with cow dung (mass ratio 1:1) for carbonization treatment under the following conditions: temperature 220 degrees, carbonization time 60 minutes, carrier gas nitrogen flow rate 50ml / min. Pass the obtained carbonization product-soil conditioner through a 0.5mm sieve for later use.

[0038] The properties of the soil samples used: pH 7.62; organic matter 9.22g / kg; TN 0.72g / kg; AP 48.76mg / kg; AK1345.87mg / kg.

[0039] 2. Soil improvement experiment design

[0040] Pot experiments were used to study the effect of amendments on soil improvement.

[0041]1). Add different amounts of soil amendments (0,5% and 10%) and 20g of compound fertilizer to the soil sample, mix well and put it into the pot. 25 wheat plants were planted in each pot. During the growth period of wheat, the appropriate amount of water should be irrigated according to its growth status to meet the normal growth and development of wheat. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com