Method for effectively reducing content of antibiotics in livestock and poultry manure

A technology of livestock and poultry manure and antibiotics, applied in chemical instruments and methods, animal husbandry, water pollutants, etc., can solve problems such as different degradation mechanisms and paths, large differences in antibiotic structures, and complicated microscopic reaction processes, so as to prevent Environmental hazards and threats to human safety, the effect of simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: reduce the method for antibiotic in manure of livestock and poultry

[0023] Experiment 1: Put livestock and poultry manure with a water content of 80% into a near-critical hydrolysis reactor at a temperature of 200°C and a pressure of 1.8Mpa, and maintain the pressure for 20 minutes to release the pressure and discharge the material. The content of antibiotics in the material can be degraded by 85%. above.

[0024] Experiment 2: Put livestock and poultry manure with a water content of 83% into a near-critical hydrolysis reactor at a temperature of 250°C and a pressure of 2.4Mpa, and maintain the pressure for 20 minutes to release the pressure and discharge the material. The content of antibiotics in the material can be degraded by 85%. above.

[0025] Experiment 3: Put livestock and poultry manure with a water content of 86% into a near-critical hydrolysis reactor at a temperature of 280°C and a pressure of 3.0Mpa, and maintain the pressure for 30 minute...

Embodiment 2

[0029] Example 2: Degradation experiments of livestock and poultry manure with different concentrations of antibiotics under high temperature and high pressure conditions

[0030] Put livestock and poultry manure with a water content of 80% into a near-critical hydrolysis reactor, the temperature is 200°C, the pressure is 1.8Mpa, and the pressure is maintained for more than 20 minutes.

[0031] The experimental results of the degradation experiments of different concentrations of antibiotics under high temperature and high pressure conditions are shown in Table 1.

[0032] The pig manure provided by Xiamen Tongan Pig Farm contains pig manure with low concentration of antibiotics; a certain amount of veterinary drug antibiotics is added to the pig manure with low concentration of antibiotics to prepare pig manure with high concentration.

[0033] Table 1 The degradation results of different concentrations of antibiotics under the same treatment conditions (μg / kg)

[0034]

[...

Embodiment 3

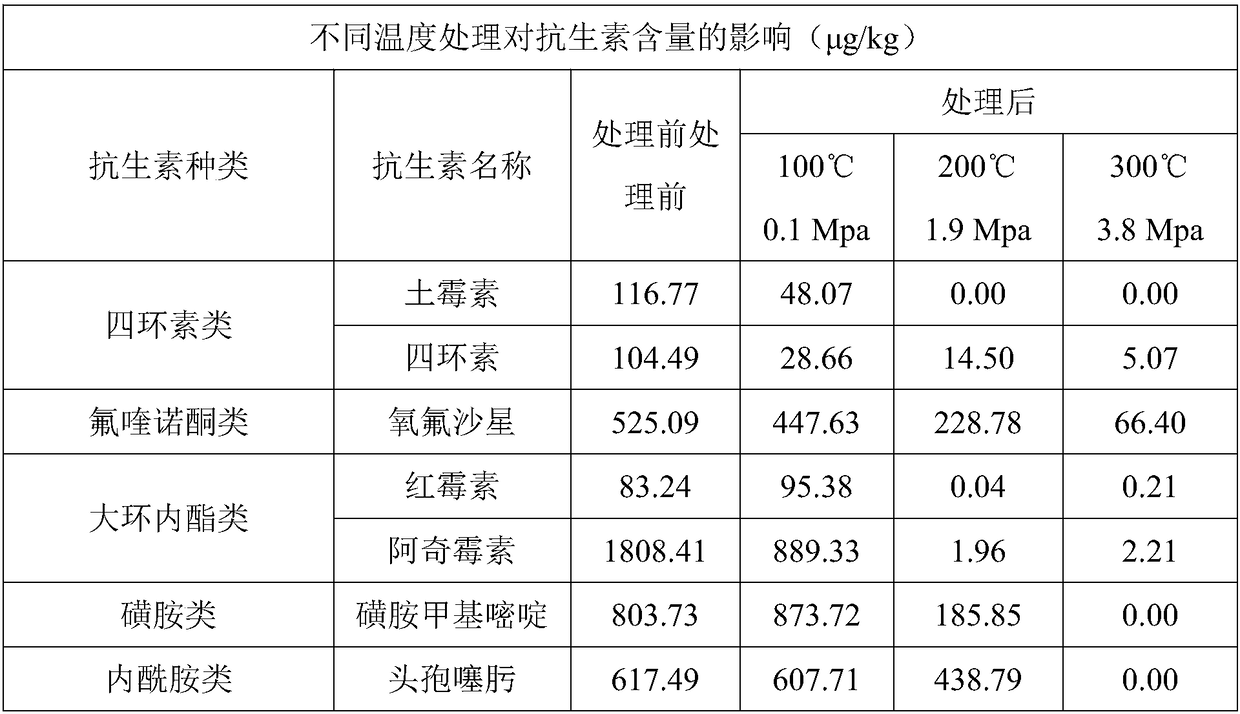

[0036] Embodiment 3: Effect experiment of different temperature and pressure treatment on antibiotic degradation and removal rate

[0037] The process steps are the same as in Example 1, and the different treatment temperatures are shown in Table 1 and Table 2. The experimental conditions of the three treatment groups were 0.1Mpa at 100°C; 1.9Mpa at 200°C; 3.8Mpa at 300°C; the time for maintaining the pressure was 20min.

[0038] Processed samples: Pig manure provided by Xiamen Tongan Pig Farm.

[0039] Table 2 The impact of different temperature treatments on the degradation of antibiotics

[0040]

[0041] As can be seen from Table 2, when the temperature is greater than 200°C (i.e. 200°C and 300°C) after treatment, the content of tetracyclines: oxytetracycline is 0, which is far lower than that before treatment (116.77) and 100°C (48.07 ) treatment; tetracycline content (200°C-14.5 and 300°C-5.07) was also much lower than before treatment (104.49) and 100°C (28.66).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com