U-shaped guide rail type multi-layer box type shuttle vehicle stereo warehouse storage and sorting method

A technology of shuttle car and three-dimensional warehouse, which is applied in the storage and sub-field of U-shaped rail type multi-layer box-type shuttle car three-dimensional warehouse, can solve the problems of increasing the number of box-type shuttle cars, equipment waste, investment and storage cost increase, etc. Effective operation capability, reduced operating costs, and simplified system configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following described embodiment.

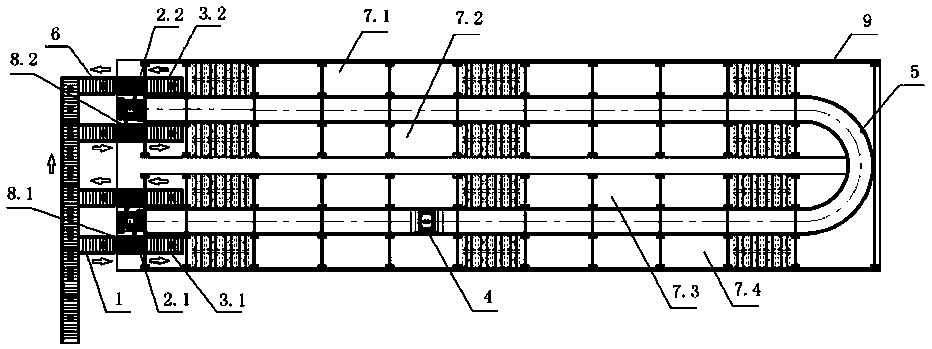

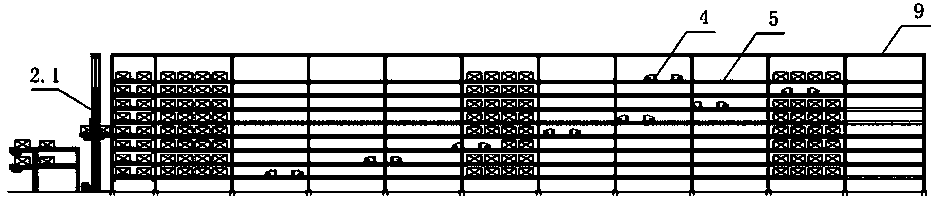

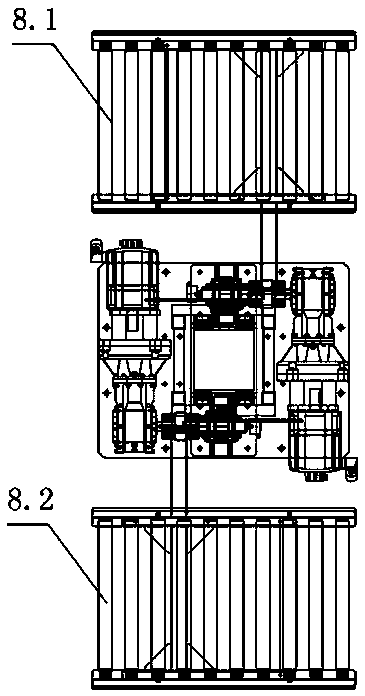

[0018] like Figure 1-4 As shown, the U-shaped guide rail type multi-layer box-type shuttle vehicle three-dimensional warehouse storage and distribution method of the present invention comprises the following steps:

[0019] The first step, when the goods are put into storage, after the goods in storage are identified by information, the goods in storage will be transported to the position of the vertical cargo elevator 2.1 at the storage entrance through the goods storage conveying line 1;

[0020] In the second step, WMS (Warehouse Management System; the abbreviation of War...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com