Sealed water recovery system of feed pump

A technology of recycling system and sealing water, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of poor adaptability of electric pumps, need for cooling water, increase power consumption of condensate pumps, etc., to achieve good adaptability and operation. Easy maintenance and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0024] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

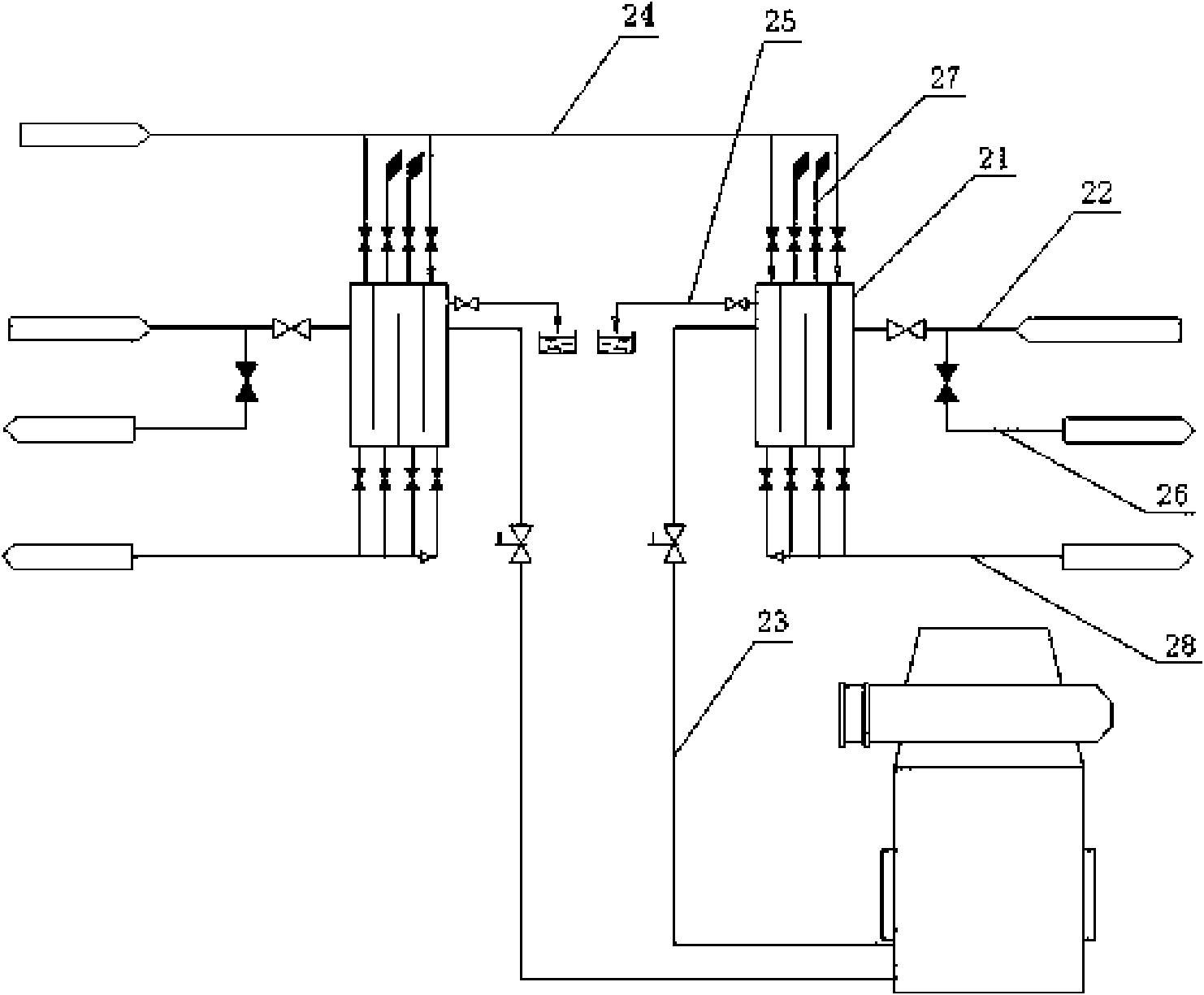

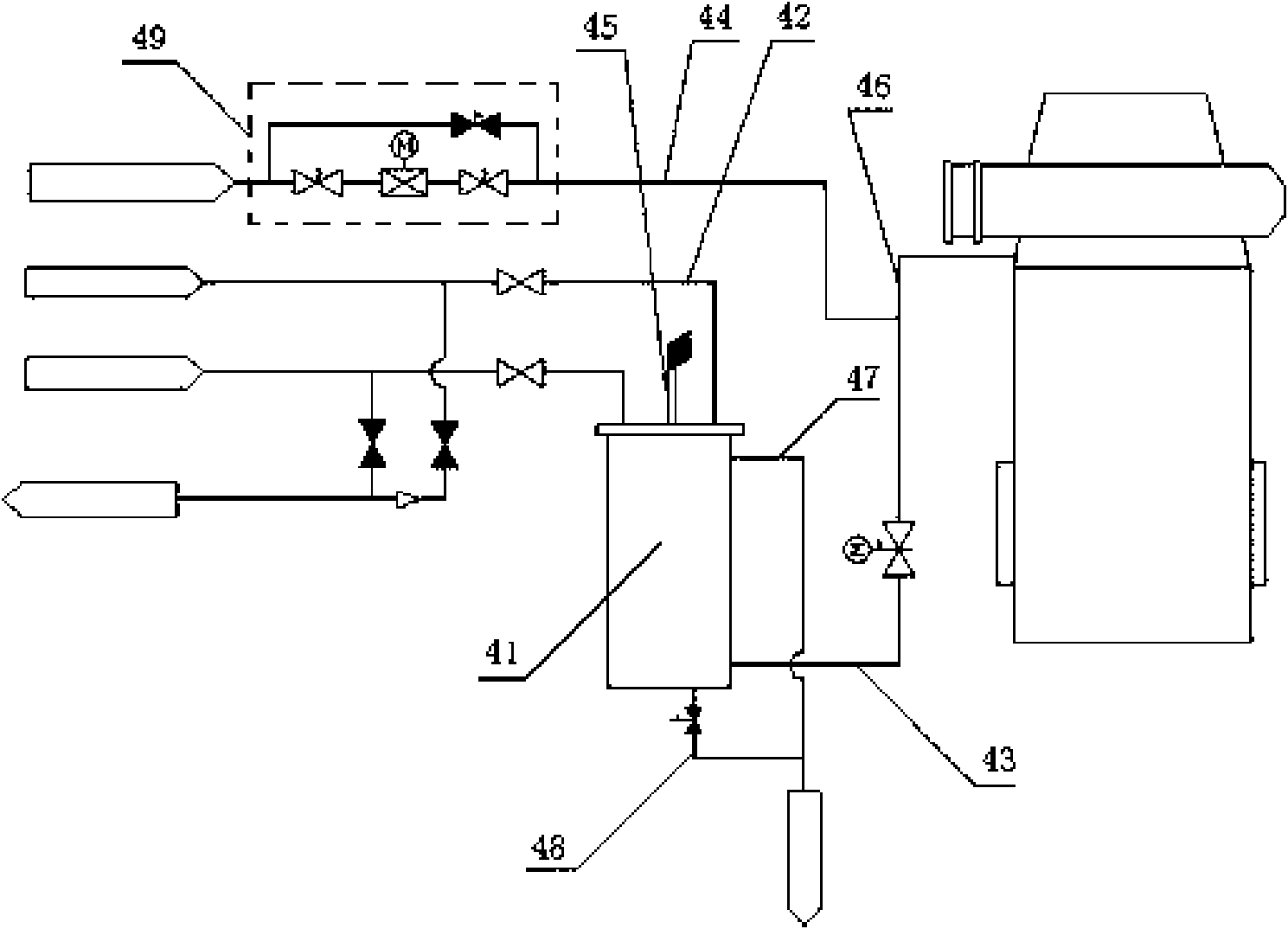

[0025] like image 3 As shown, a feed water pump seal water recovery system includes: recovery water tank 1, seal water inlet pipe 2 and valve 3, seal water outlet pipe 4 and return water pipe regulating valve group 5, exhaust pipe 6, overflow pipe 7. Discharge pipeline 8 and normally closed valve 9.

[0026] One end of the sealed water inlet pipe 2 is connected to the water outlet of the shaft end of the water pump, the other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com