Gear milling clamp suitable for various automobile steering device rack pistons

A kind of automobile steering gear, multi-variety technology, applied in the direction of manufacturing tools, metal processing equipment, gear and tooth manufacturing devices, etc., can solve the problems of inapplicable replacement parts, unsuitable rack and gear milling machines, small quantities, etc., to achieve precise positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

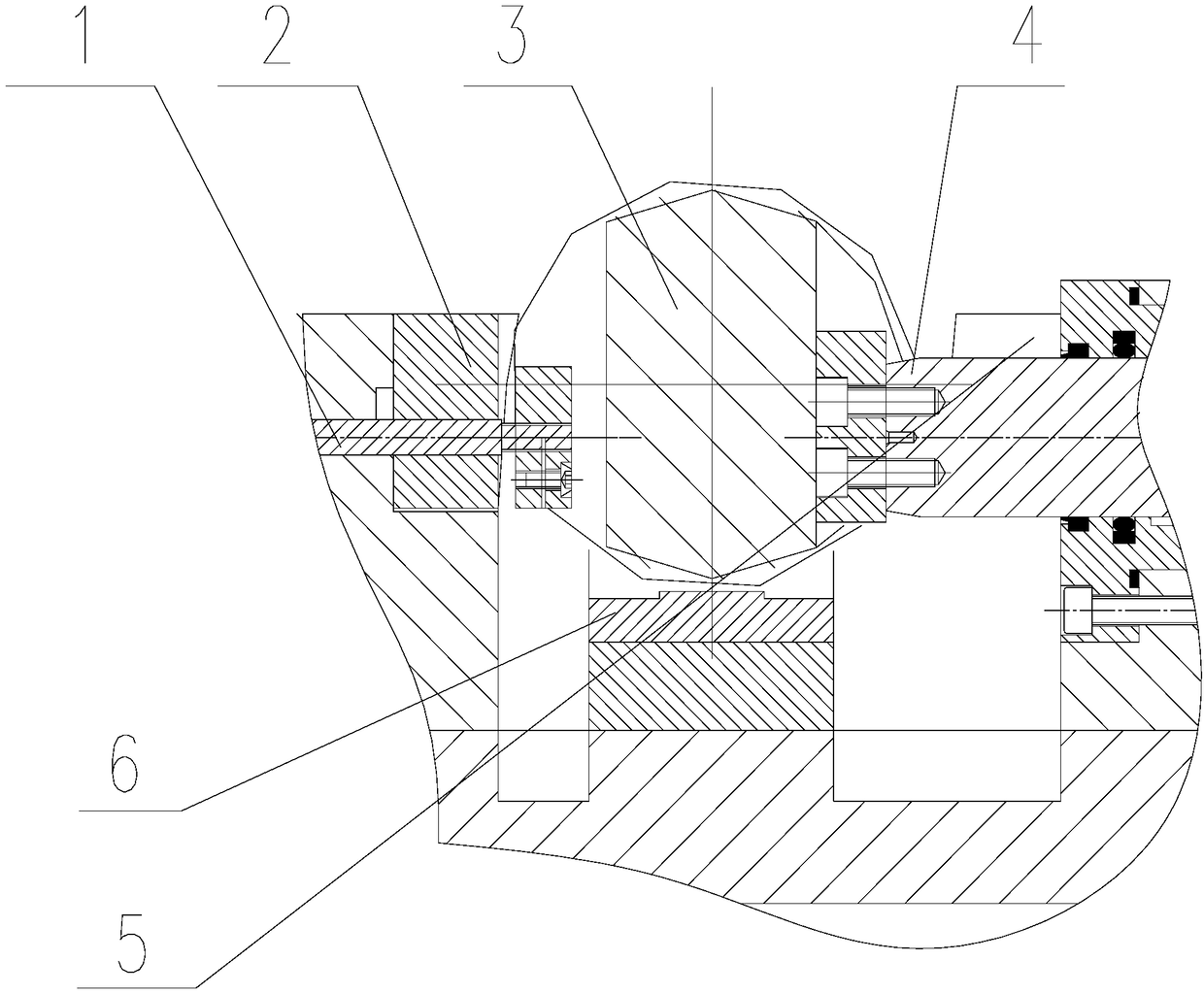

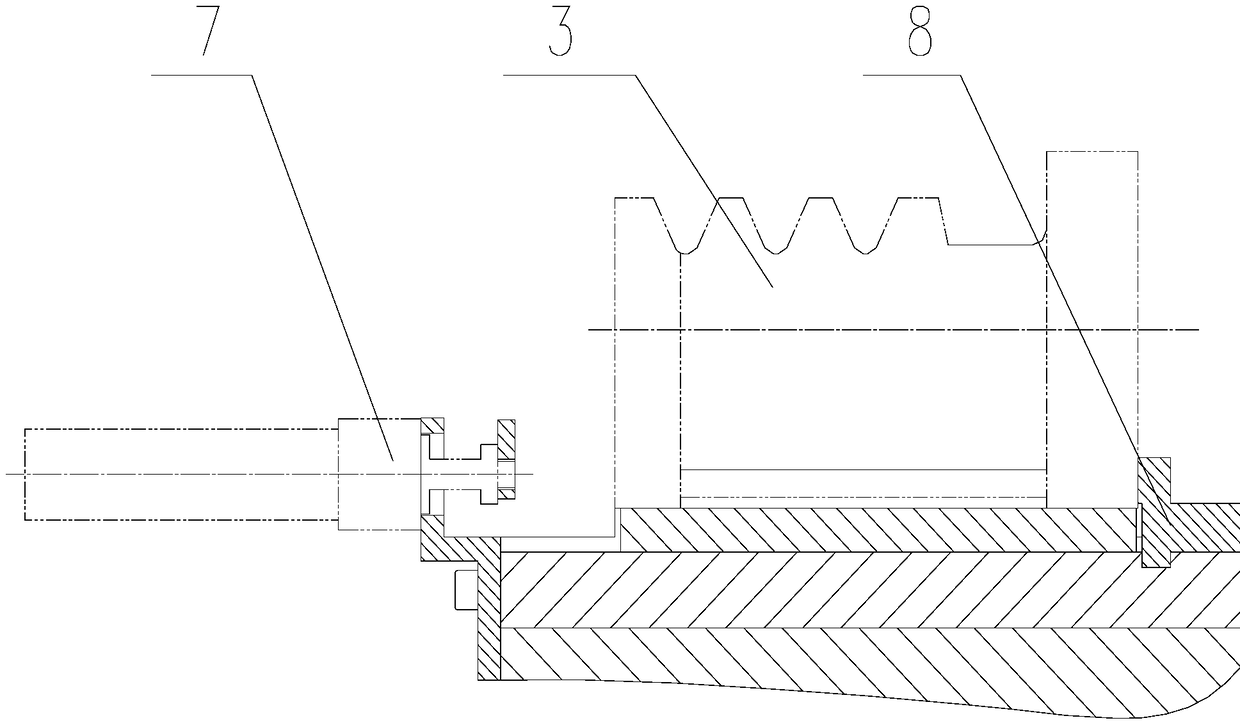

[0020] Such as Figure 1-2 , a fixture suitable for multi-variety automotive steering gear rack piston milling, which includes a guide shaft 1, an arc jaw 2 is mounted on the guide shaft 1 for sliding fit, and an adjustment pad 6 is arranged at the bottom of the fixture. The adjustment pad 6 can adjust the height of the workpiece; ensure that the center height of all kinds of workpieces is consistent; the opposite side of the guide shaft 1 is provided with a radial positioning block 5, and the guide shaft 1 cooperates with the radial positioning block 5 and the piston rod Radial positioning of the workpiece is used to facilitate the feeding mechanism to place the workpiece at the same position, and it is also taken out from the same position when picking up the workpiece, and the workpiece is prevented from rotating; the opposite side of the arc-shaped j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com