Test box for testing low-temperature mechanical performance of splicing fitting and test method of test box

A technology for mechanical properties and splicing fittings, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc., can solve the problem of failing to meet the low-temperature mechanical performance testing requirements of splicing fittings, and achieve convenient adjustment and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

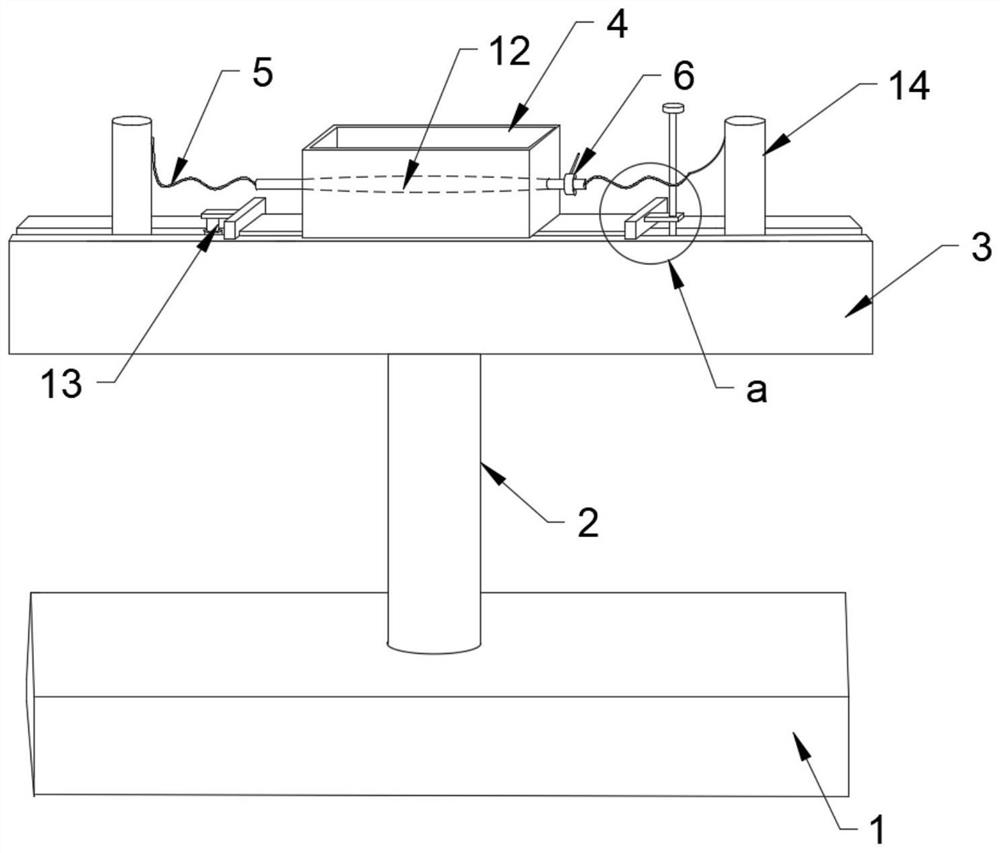

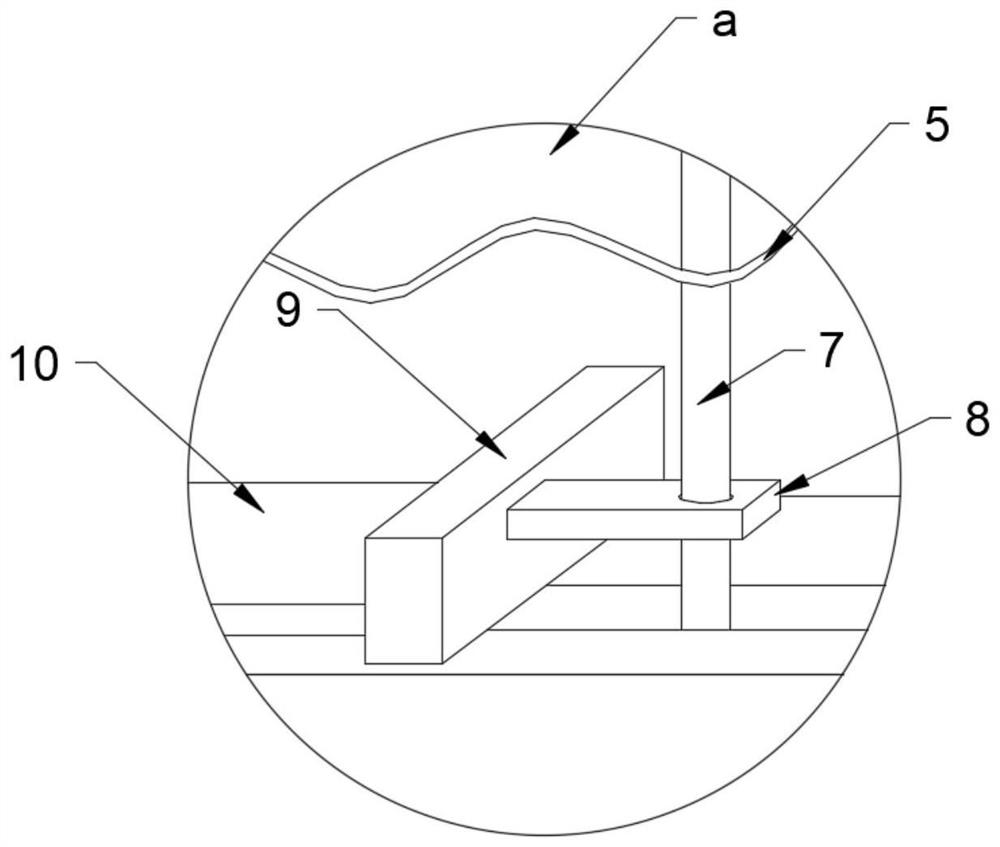

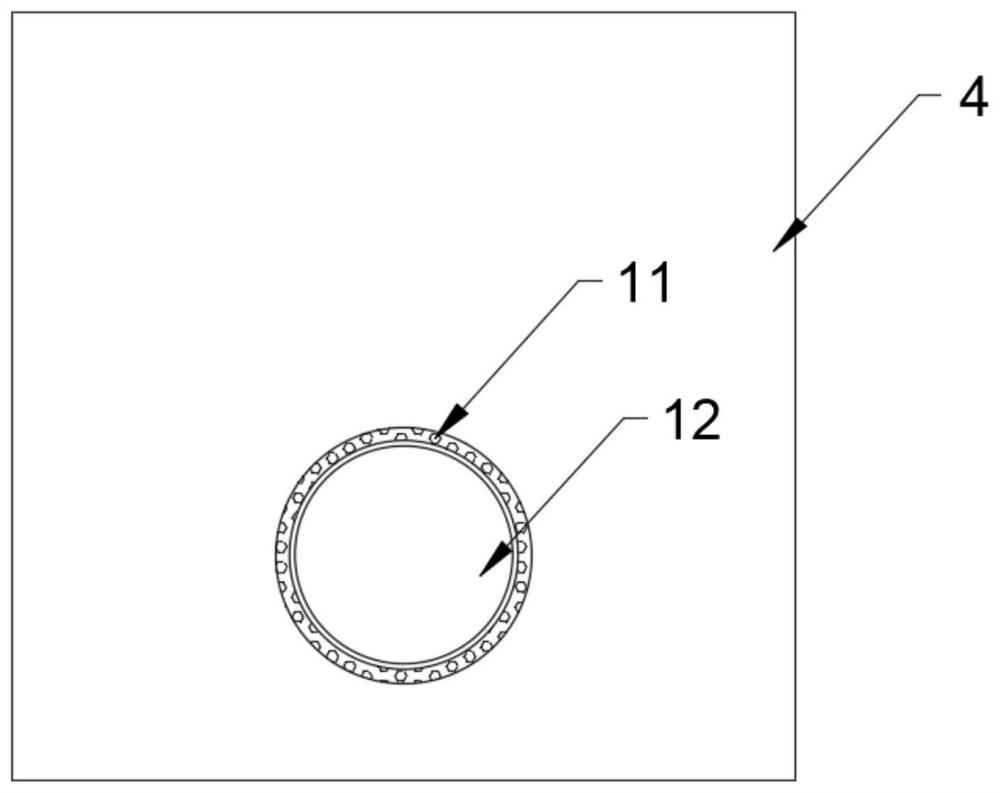

[0052] A test box for testing the low-temperature mechanical properties of continuous fittings, similar to Example 1, the difference is that the metal box body 4 is made of 5mm thick stainless steel plates and processed into four plates of 960mm*200mm specifications, and the test box is welded by manual argon arc welding. Three plates are welded to form the side and bottom plate of the test box, and the remaining one plate is used as a cover plate; two stainless steel plates of 200mm*200mm*5mm are welded to form the side plate of the test box. The test metal 12, that is, the maximum diameter of the shaft part of the fitting to be tested is 76mm, and a φ78.6mm circular hole is opened at a certain position on both sides of the test box, so that the test metal 12 can pass through the test box; according to the size of the holes at both ends of the side plate, customized resistance The low-temperature PTFE sealing ring is used to fix the sealing ring at the holes at both ends to re...

Embodiment 3

[0060] A test box for testing the low-temperature mechanical properties of continuous fittings, which is similar to Example 1, except that a sealing cover 41 is provided on the upper part of the metal box 4, and a flow rate adjustment component is provided on the sealing cover. Such as Figure 5 As shown, the flow rate adjustment assembly includes an adjustment box 15 , and a miniature sealing plate is movably connected to the upper part of the adjustment box 15 to avoid affecting the temperature in the metal box 4 . The adjustment box 15 is a hollow box body, and the adjustment box 15 is provided with a deceleration plate 16, one side of the deceleration plate 16 is connected to the lotus leaf connector and is movably connected to the inner wall of the adjustment box 15, and the inner wall of the adjustment box 15 is provided with a fixed block 17, and the deceleration plate 16 The other side is supported by the fixed block 17. Therefore, the speed brake 16 can be opened dire...

Embodiment 4

[0063] A test chamber for testing low-temperature mechanical properties of continuous fittings, similar to Example 3, the difference is that, as Figure 5 As shown, an adjustment plate 22 is provided on the top of the speed brake 16 . A fixing hole 18 is arranged in the middle of the deceleration plate 16 , and a rotating shaft 19 is fixedly connected in the middle of the adjusting plate 22 , the rotating shaft 19 can be inserted into the fixing hole 18 , and the adjusting plate 22 can rotate around the fixing hole 18 through the rotating shaft 19 . Adjusting plate 22 top is provided with portable post 20, can choose whether to use as required, can directly adjust plate 22 be taken out from regulating box 15 by carrying post 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com