Preparative separation and purification device

A technology for separation, purification and holding devices, which is applied in separation methods, measurement devices, material separation, etc., to achieve the effect of improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

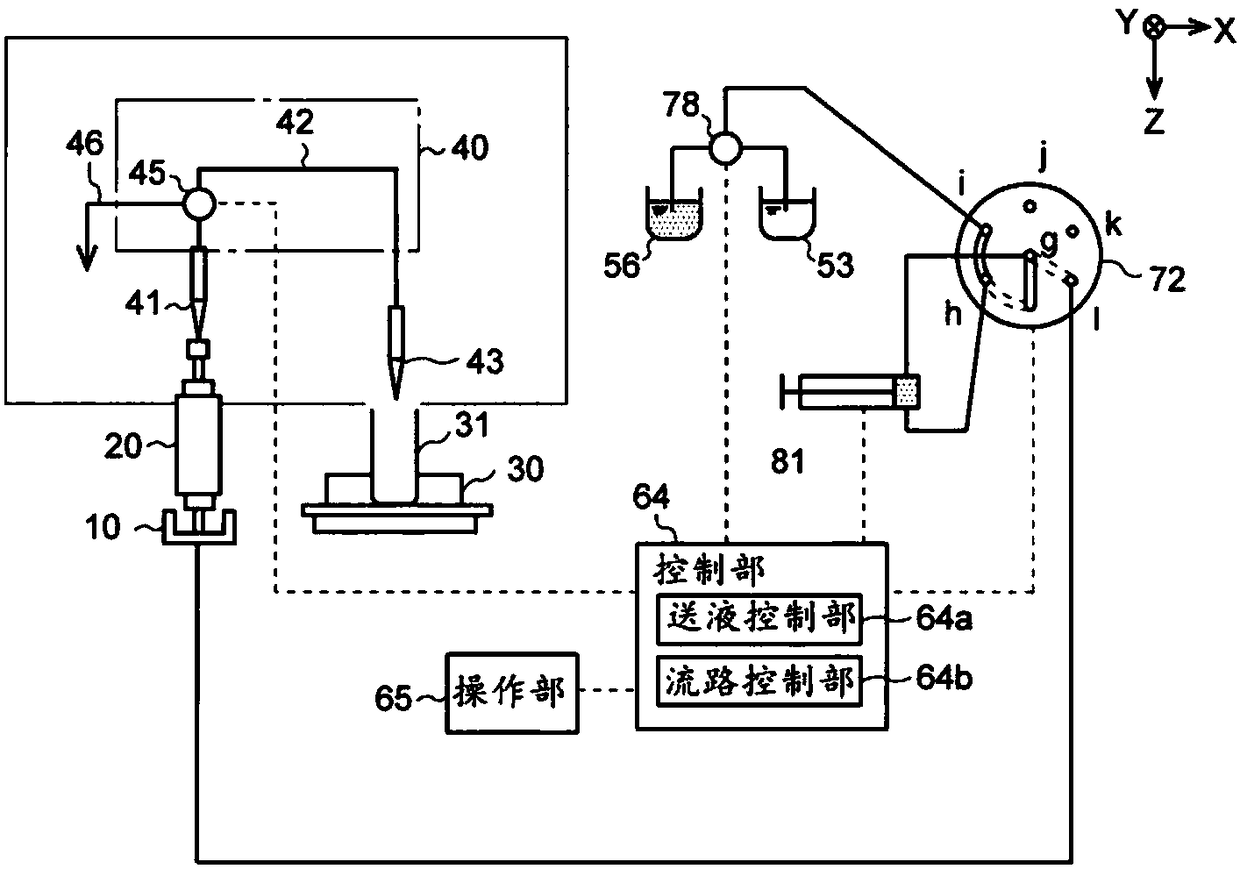

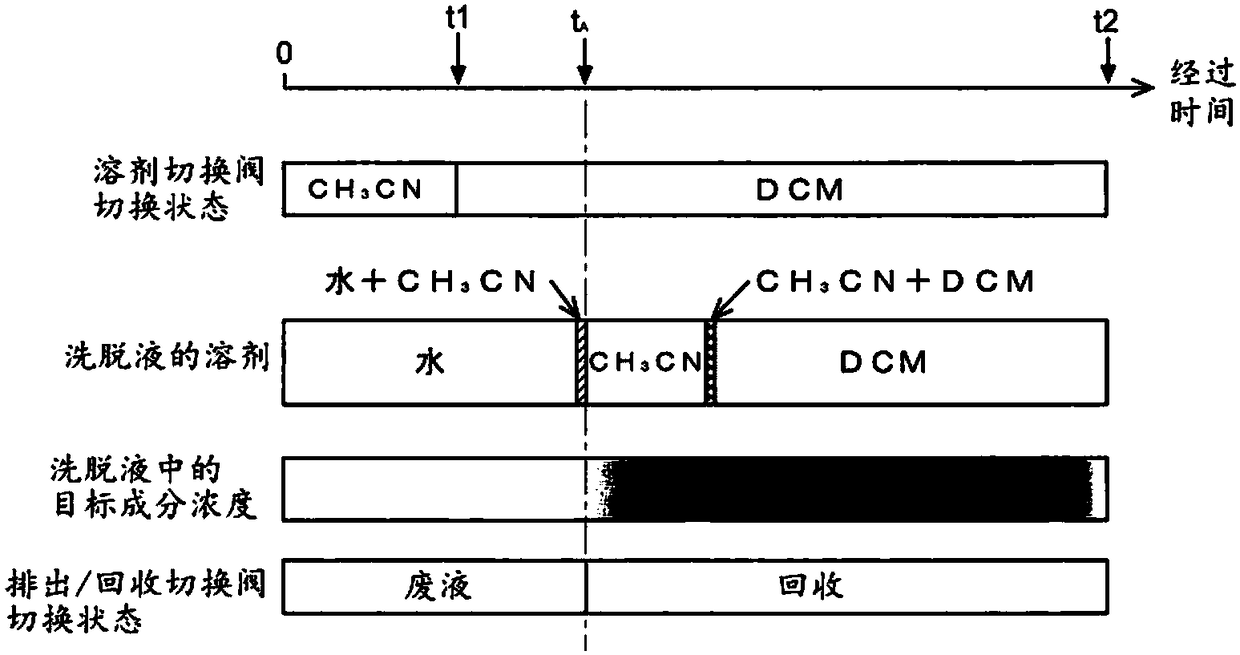

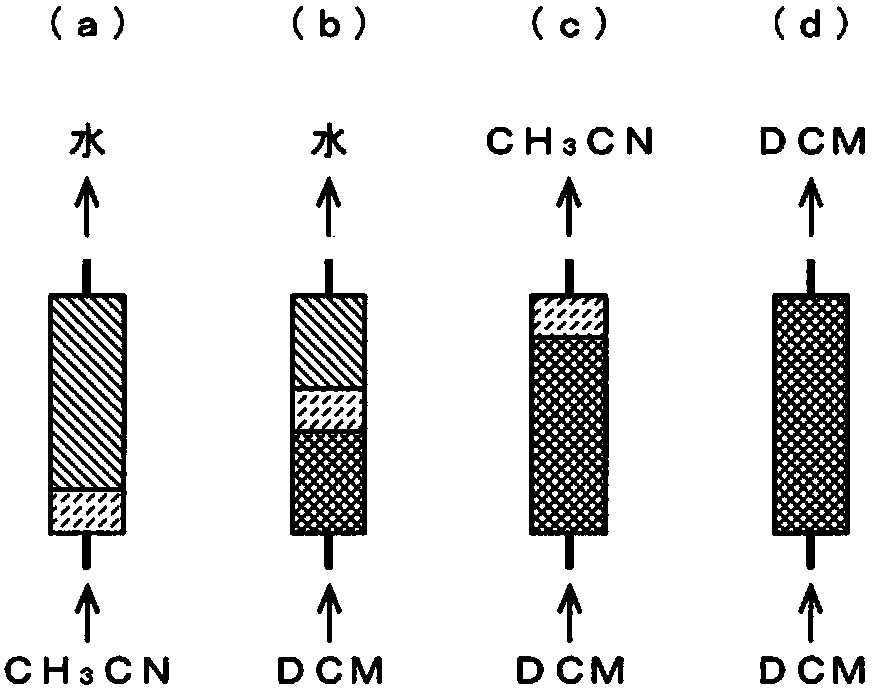

[0037] figure 1 It is a schematic configuration diagram of a separation and purification apparatus according to an embodiment of the present invention. This separation and purification device is a device for recovering, from the trap column, the target component separated by a separation liquid chromatograph (not shown) and captured by the adsorbent filled in the trap column.

[0038] The column frame 10 (holding device in the present invention) holds the well column 20 upright with the inlet end facing down and the outlet end facing up. In addition, target components separated by a separation liquid chromatograph (not shown) are preliminarily captured in the trap column 20 .

[0039] A recovery container 31 for recovering the target component eluted from the trap column 20 is housed in the recovery container rack 30 .

[0040] Above the column rack 10 and the recovery container rack 30 , a recovery head 40 for sending the eluent from the trap column 20 to the recovery conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com