Steel for mechanical structures and induction hardened steel parts

A mechanical structure and high-frequency quenching technology, which is applied in the fields of high-frequency hardened steel parts, mechanical structural steel and high-frequency hardened steel parts, can solve the problems of decreased hardenability, difficulty in completing the transformation to austenite, and unclear , to achieve excellent surface fatigue strength, excellent machinability and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

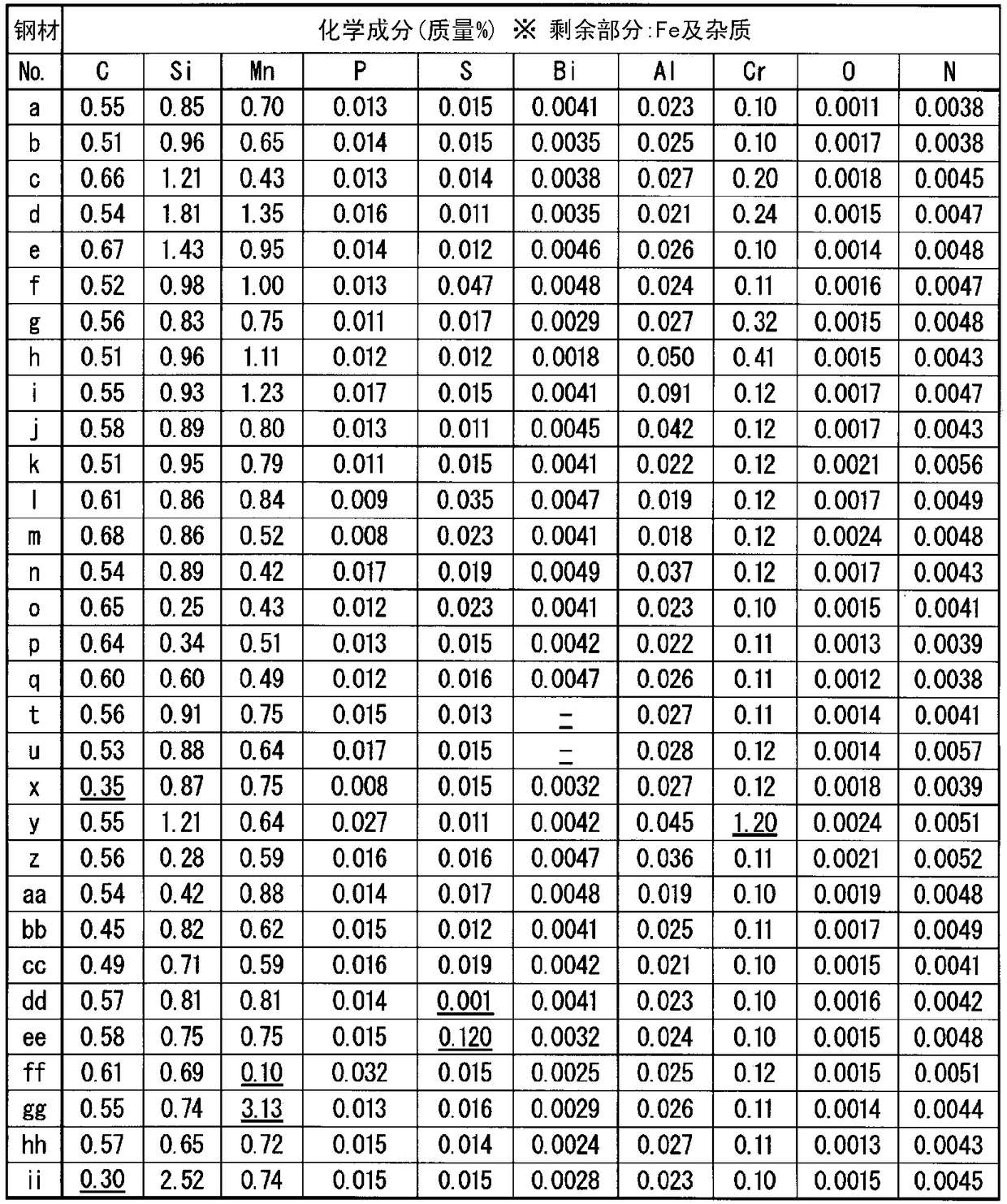

[0139] The present invention will be described in detail below through examples. The conditions in the examples are one example of conditions employed to confirm the feasibility and effects of the present invention, and the present invention is not limited to this one example of conditions. As long as the object of the present invention can be achieved without departing from the gist of the present invention, various conditions can be employed in the present invention.

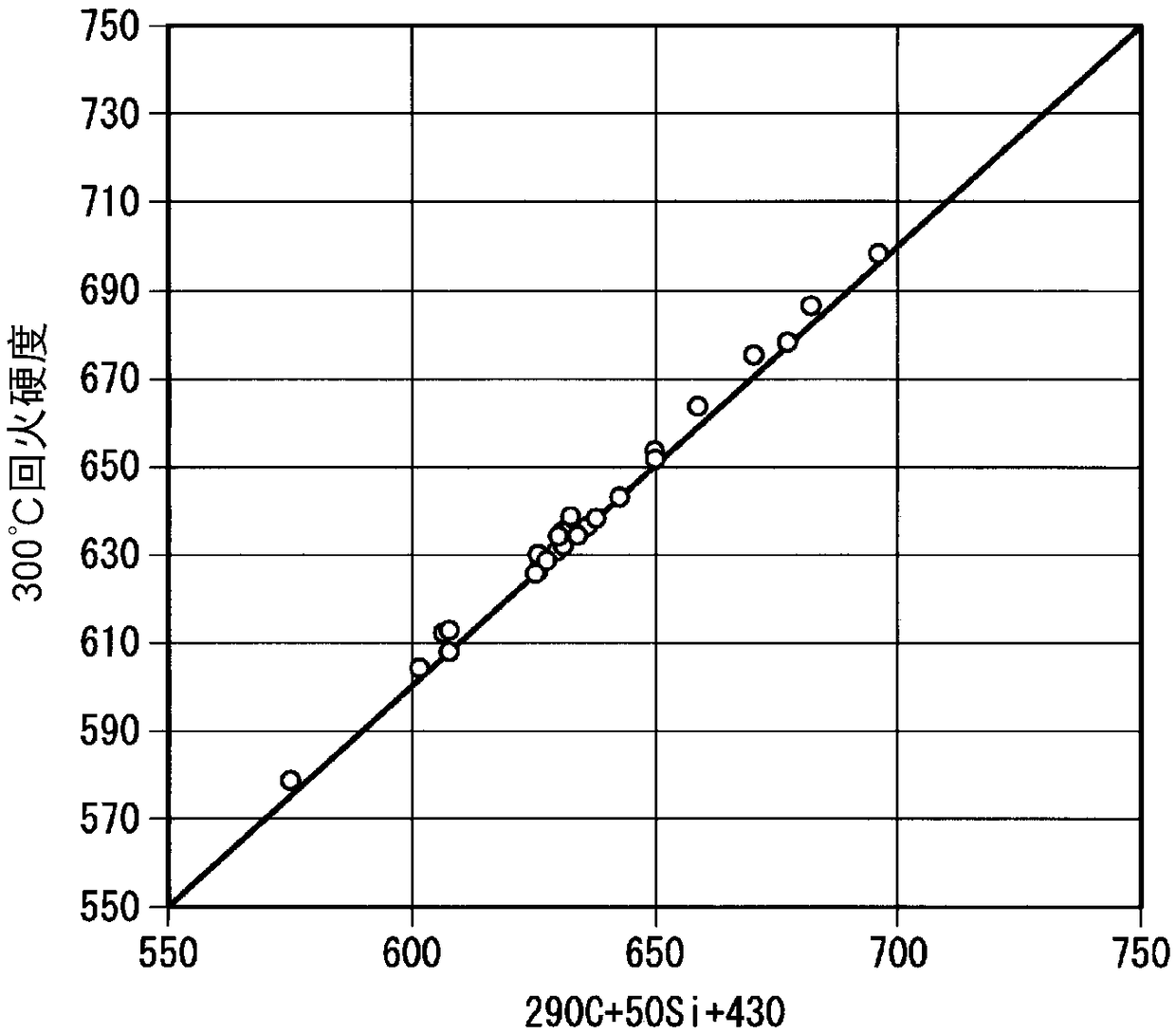

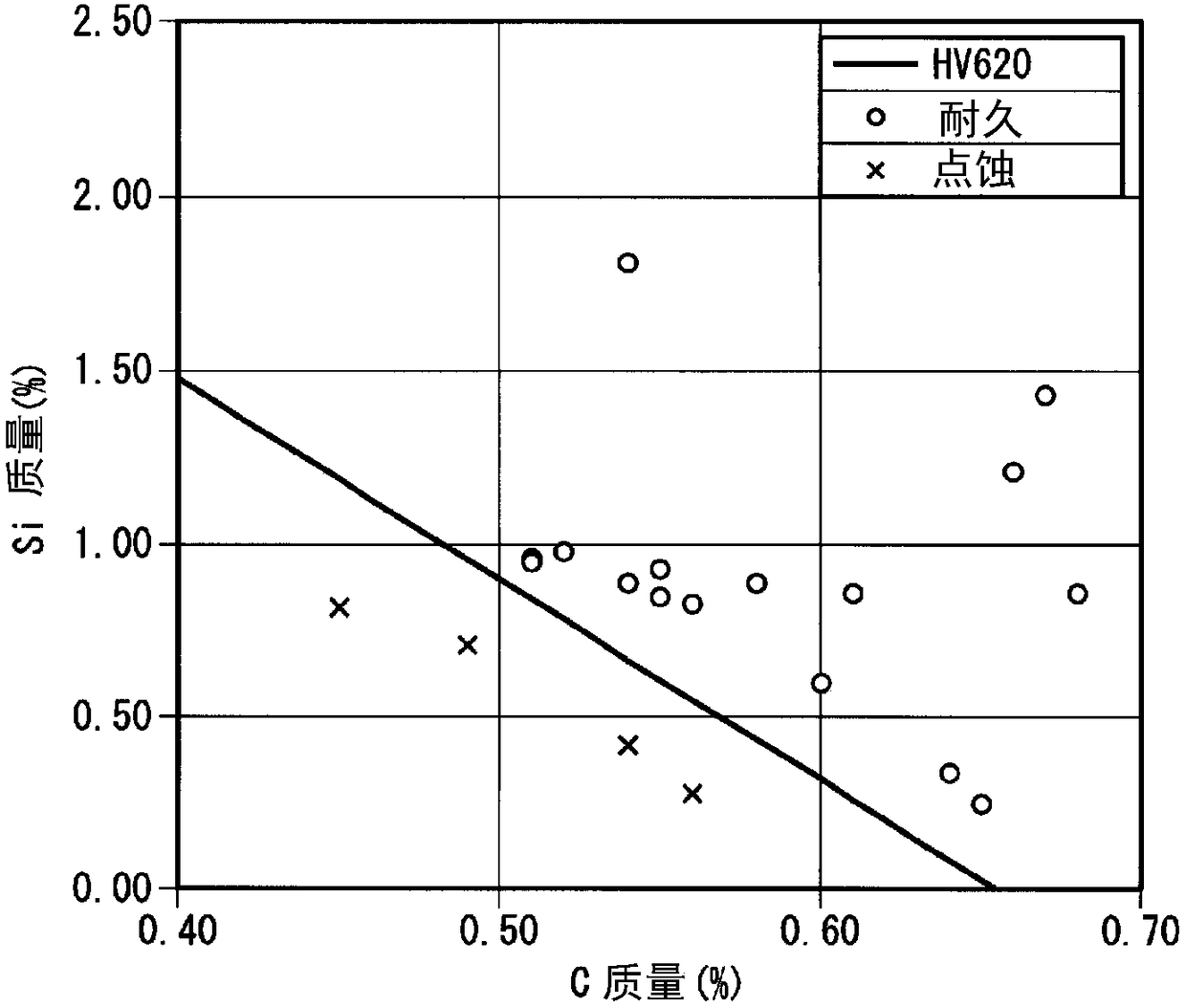

[0140] Steel materials No.a to ii having the chemical compositions shown in Table 1 and Table 2 were melted in a 270-ton converter, and continuously casted using a continuous casting machine to manufacture a 220×220 mm square billet. Pressing is applied at a stage in the middle of solidification of continuous casting. In the continuous casting of the slab, the average cooling rate in the temperature range from the liquidus temperature to the solidus temperature at a position at a depth of 15 mm from the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com