A kind of testing method of electrochemical sensor

A test method and sensor technology, applied in the field of electrochemical detection, can solve the problems that the electrode cannot completely absorb the sample, the electrode cannot be completely filled, and the deviation is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Test method of the present invention

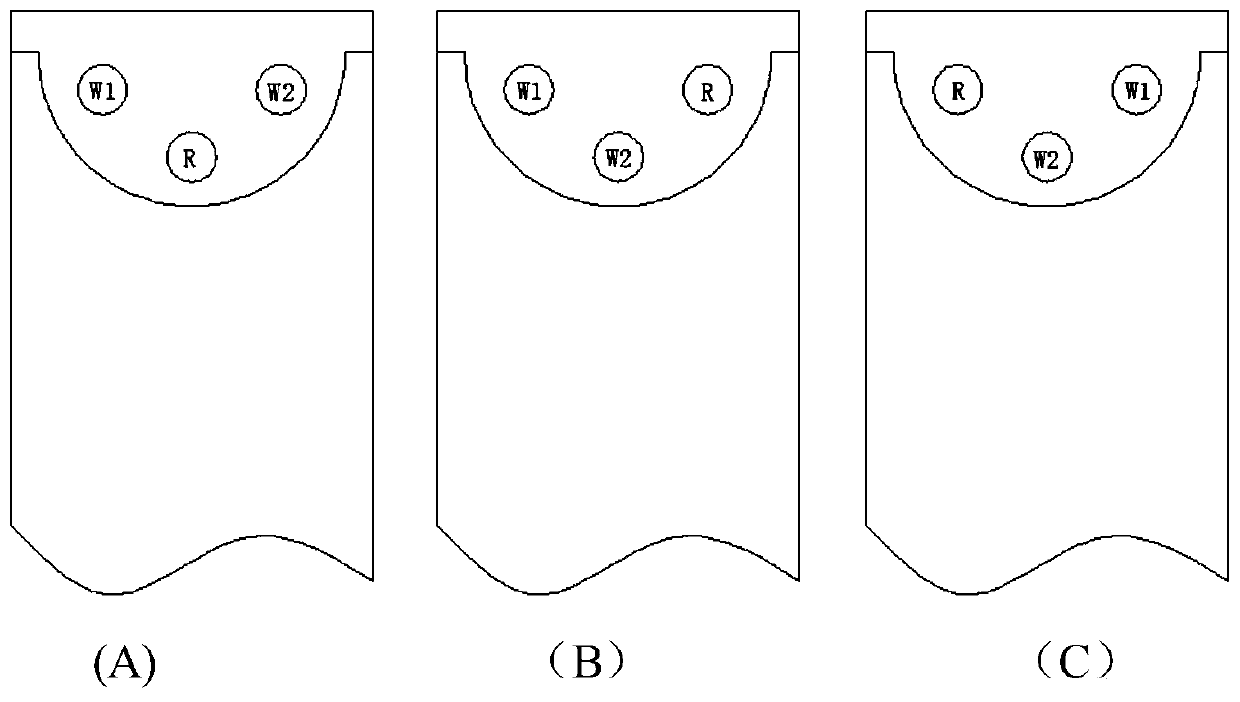

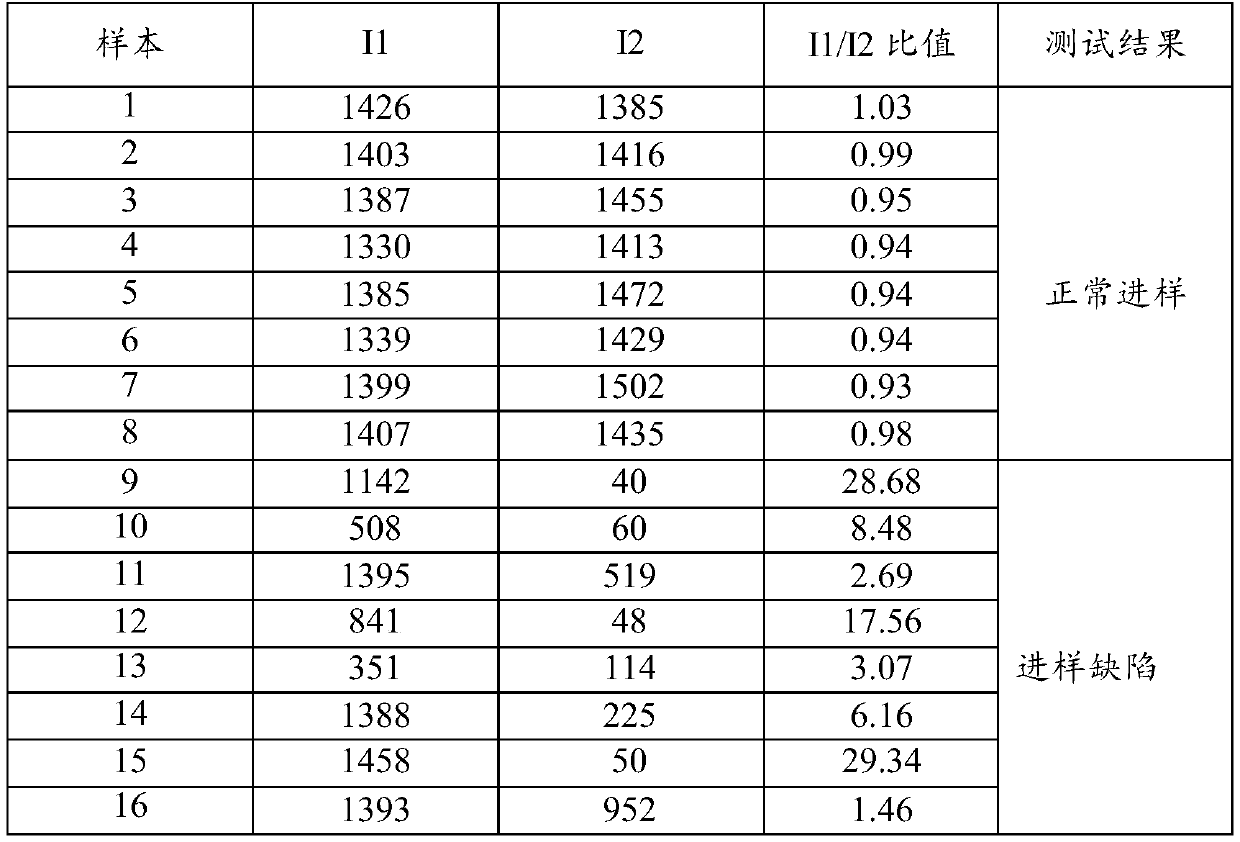

[0035] Add the sample to be tested, and the sample to be tested enters the sensor from the top sample inlet of the sensor. First, the sample fills the first electrode and the second electrode (W1 and R), so that a current loop is formed between the first electrode and the second electrode. The instrument connected to the sensor will automatically turn on under the drive of its internal power-on circuit, and the sample to be tested chemically reacts with the reagents on the two working electrodes of the electrochemical sensor, and two current signals are read within 15 to 30 seconds after the instrument starts timing. , corresponding to I 1 and I 2 , according to I 1 / I 2 The ratio of judging the injection situation. The judgment method includes the following steps: set the preset parameter range (A, B), when A≤I 1 / I 2 When ≤B, the injection is correct.

Embodiment 2

[0036] Embodiment 2 Test method of the present invention

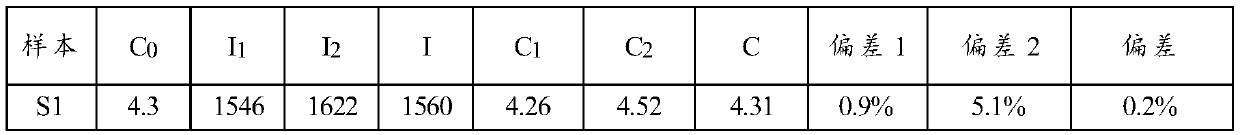

[0037] Add the sample to be tested, and the sample to be tested enters the sensor from the top sample inlet of the sensor. First, the sample fills the first electrode and the second electrode (W1 and R), so that a current loop is formed between the first electrode and the second electrode. The instrument connected to the sensor will automatically turn on under the drive of its internal power-on circuit, and the sample to be tested chemically reacts with the reagents on the two working electrodes of the electrochemical sensor, and two current signals are read within 15 to 30 seconds after the instrument starts timing. , respectively, to obtain two current values I 1 and I 2 , according to I 1 , I 2 Calculate the current value I to obtain the concentration of the substance to be tested in the sample to be tested;

[0038] Among them, the calculation method of the current value I is: I=a 1 I 1 +b 1 I 2 , 0.5≤a≤1...

Embodiment 3

[0039] Embodiment 3 Test method of the present invention

[0040]Add the sample to be tested, and the sample to be tested enters the sensor from the top sample inlet of the sensor. First, the sample fills the first electrode and the second electrode (W1 and R), so that a current loop is formed between the first electrode and the second electrode. The instrument connected to the sensor will automatically turn on under the drive of its internal power-on circuit. The sample to be tested chemically reacts with the reagents on the two working electrodes of the electrochemical sensor, and two current signals are read within 15 to 30 seconds after the instrument starts timing. , respectively, to obtain two current values I 1 and I 2 , according to I 1 , I 2 Calculate the current value I to obtain the concentration of the substance to be tested in the sample to be tested;

[0041] Among them, the calculation method of the current value I is:

[0042] Set the preset parameter ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com