Method for assisting gravity drainage by means of solvent and superheated steam

A technology of superheated steam and auxiliary gravity, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., and can solve the problems of restricting oil production rate, increasing steam specific volume and increasing enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

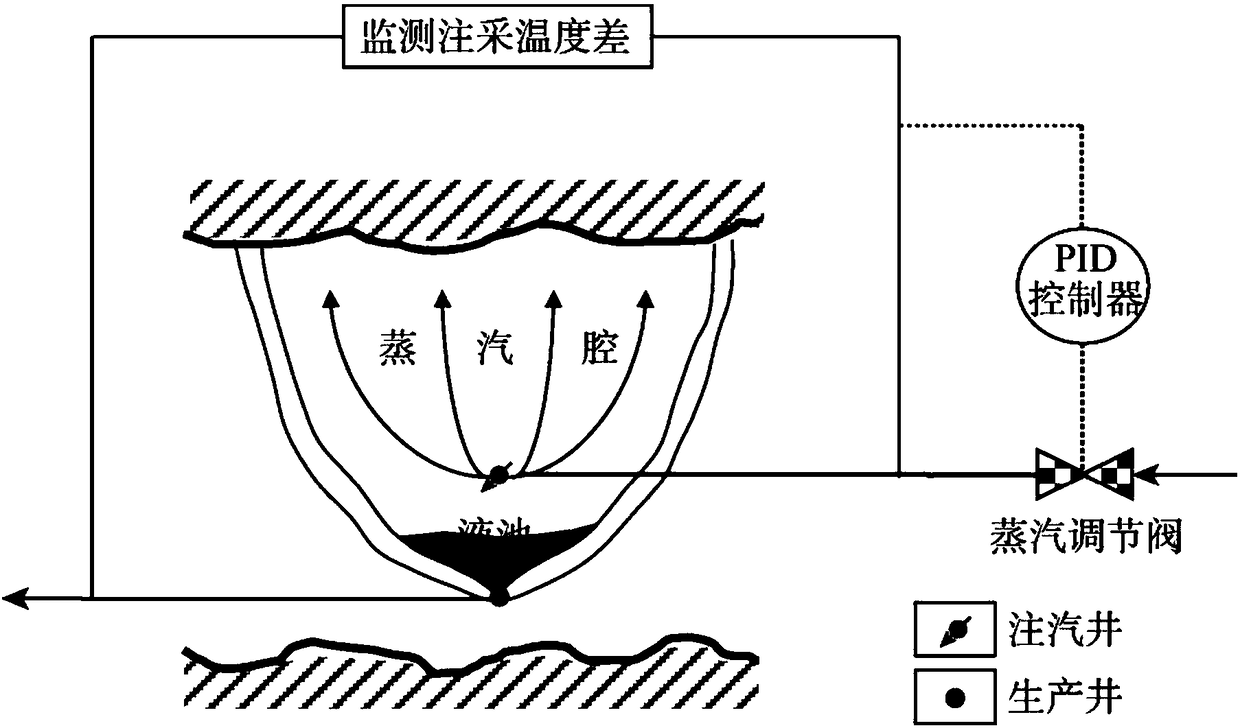

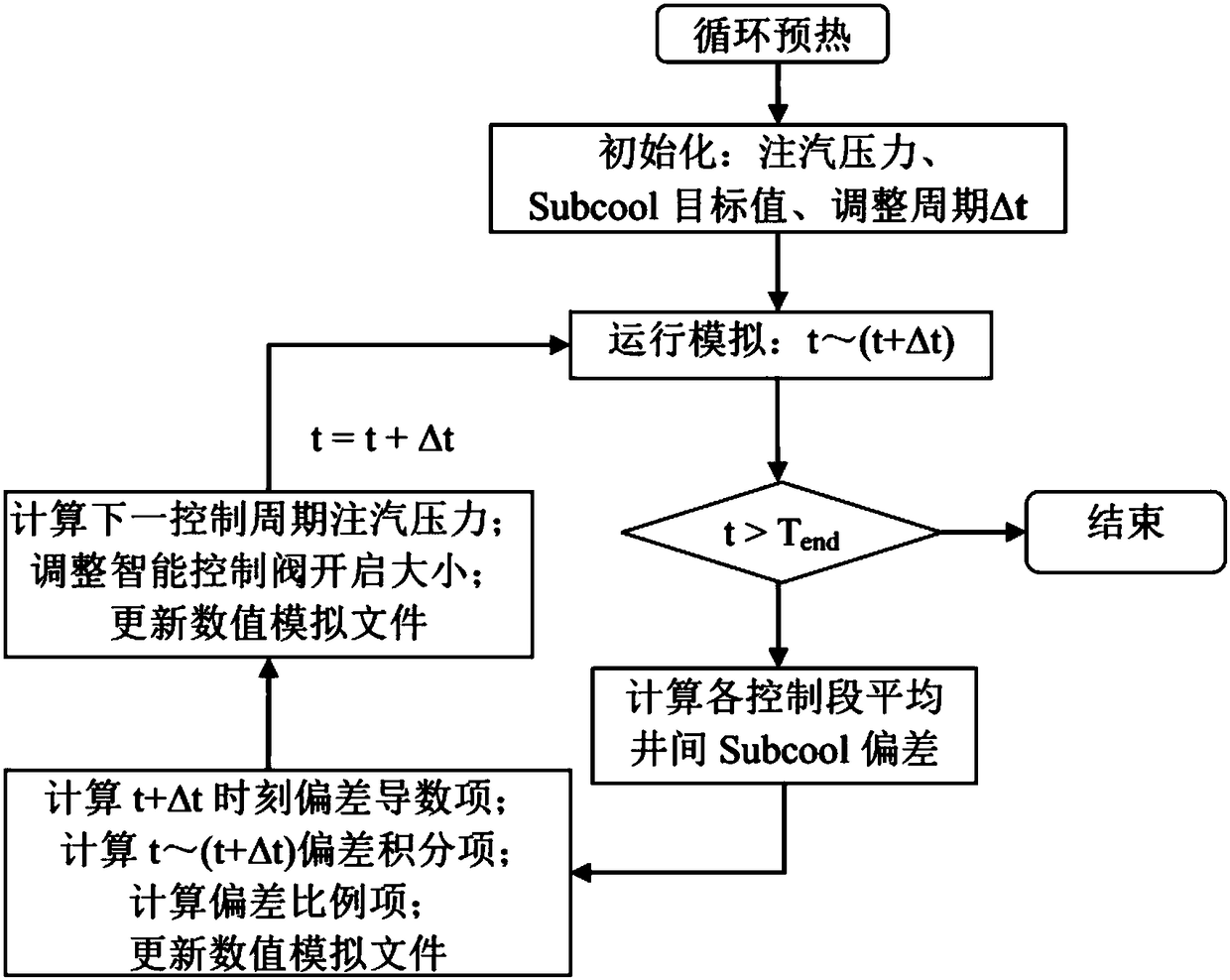

[0077] This embodiment provides a method of using solvent and superheated steam to assist gravity drainage.

[0078] In this example, an oil sand block is taken as the research object. This block is shallowly buried, with a buried depth of 170-200m, the corresponding maximum operating pressure is less than 2.3MPa, and the average thickness is relatively thin, only 15-20m. The viscosity of degassed crude oil is greater than 10 under the condition 7 mPa.s, the original reservoir pressure and temperature are 0.4MPa and 6°C, respectively.

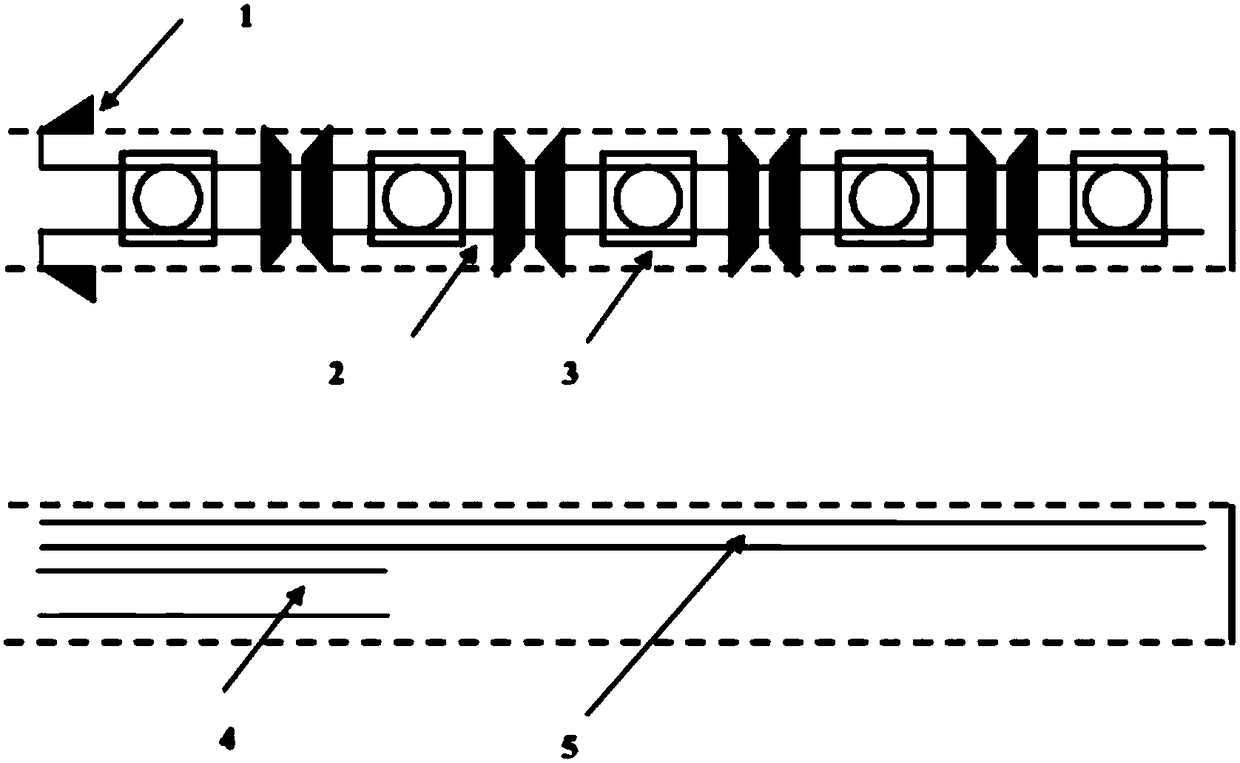

[0079] 1) According to the geological parameters and fluid properties of the reservoir, it is determined to use the double horizontal well SAGD technology for platform well layout;

[0080] The length of the horizontal well is 850m, the vertical distance between injection and production wells is 5m, and the horizontal well spacing is 125m; The extension length of the short pipe is 100m from the heel of the screen pipe;

[0081] Such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com