Subway ballast bed concrete replacing process in special limiting condition

A restrictive condition, concrete technology, applied in the direction of road, track, ballast layer, etc., can solve the problems of concrete and internal steel reinforcement disturbance, concrete disturbance, no scheme, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

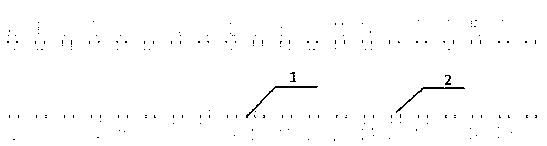

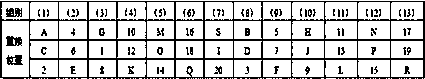

[0047] A concrete replacement process for a railway track bed under special constraints, including the following steps:

[0048] (1) Set the curtain water stop

[0049] Drill three rows of grouting holes at both ends of the construction area in a plum blossom distribution, with a hole distance of 300mm and a hole depth of 500mm. Install water-stop needles to ensure that the needles are intact and have no leakage, and then pour modified epoxy resin water-stop grout. Prevent external water from intruding into the construction site.

[0050] (2) Set up safety facilities to brace and support the track

[0051] After cleaning the track center, use hard wood to reinforce and fix the empty track bed and under the small sleepers. Reinforce the concrete roof of the ballast bed on both sides of the track center to prevent the ballast bed from sinking due to train vibration.

[0052] When the concrete of the ballast bed is removed, the gauge bar is set to prevent the lateral displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com