Method for stirring fermentation materials in dry fermentation tank

A stirring method and fermenter technology, which are applied to specific-purpose bioreactors/fermenters, biochemical equipment and methods, and bioreactor/fermenter combinations, etc. problems such as large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

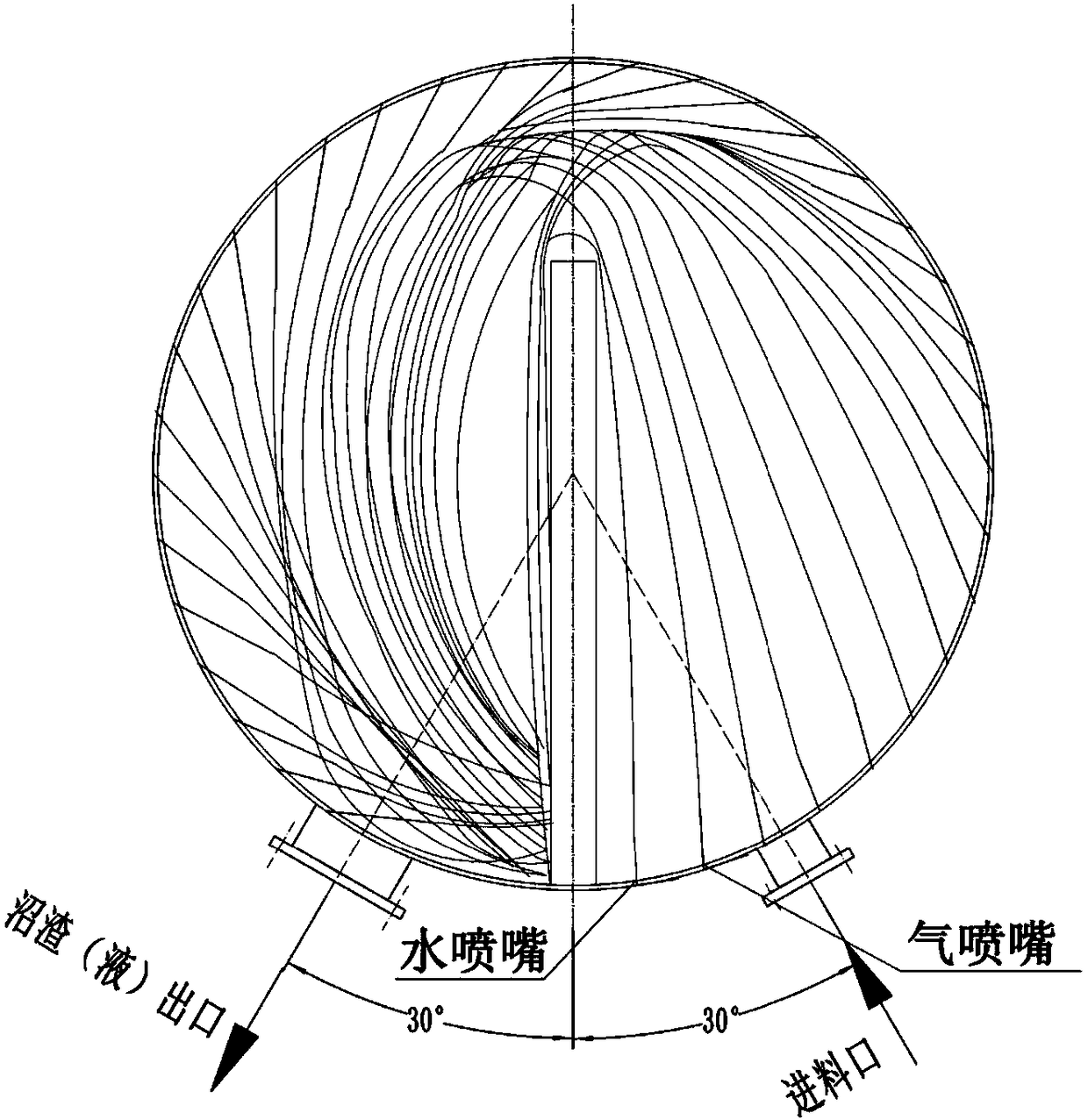

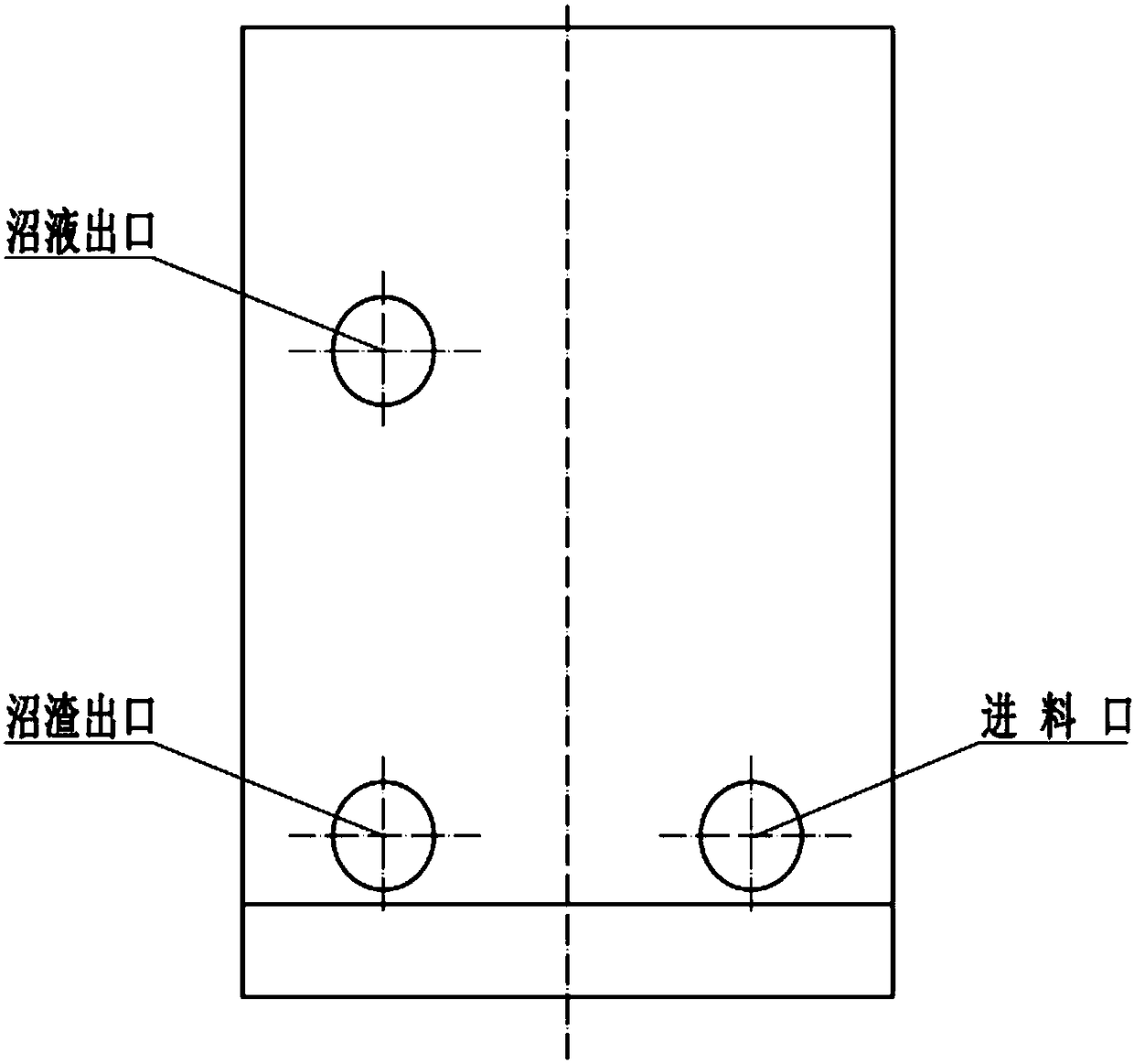

[0011] The stirring method provided by the present invention is to alternately install several rows of high-pressure gas nozzles and several rows of high-pressure water nozzles on the inner wall of the fermentation tank, and each row of nozzles forms a certain angle with the tank wall. And the included angles between the nozzles of each row and the tank wall are different. The distance between the nozzles on each row is between 30cm-50cm. According to the principle of submerged jet in jet theory. After the high-pressure gas in the high-pressure gas nozzle is ejected, a large Reynolds number gas jet with concentrated energy is formed. In the fermented product, it is a free turbulent flow without solid wall constraints. Driven by this turbulent jet gas, the surrounding materials are sucked in and continuously expanded, and flow downstream to form a turbulent (gas) flow. After the high-pressure water is sprayed out through the nozzle, a high Reynolds number water jet with conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com