Porcelain bottle cleaning robot

A technology for cleaning robots and porcelain bottles, which is applied to cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc. Easy to operate and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

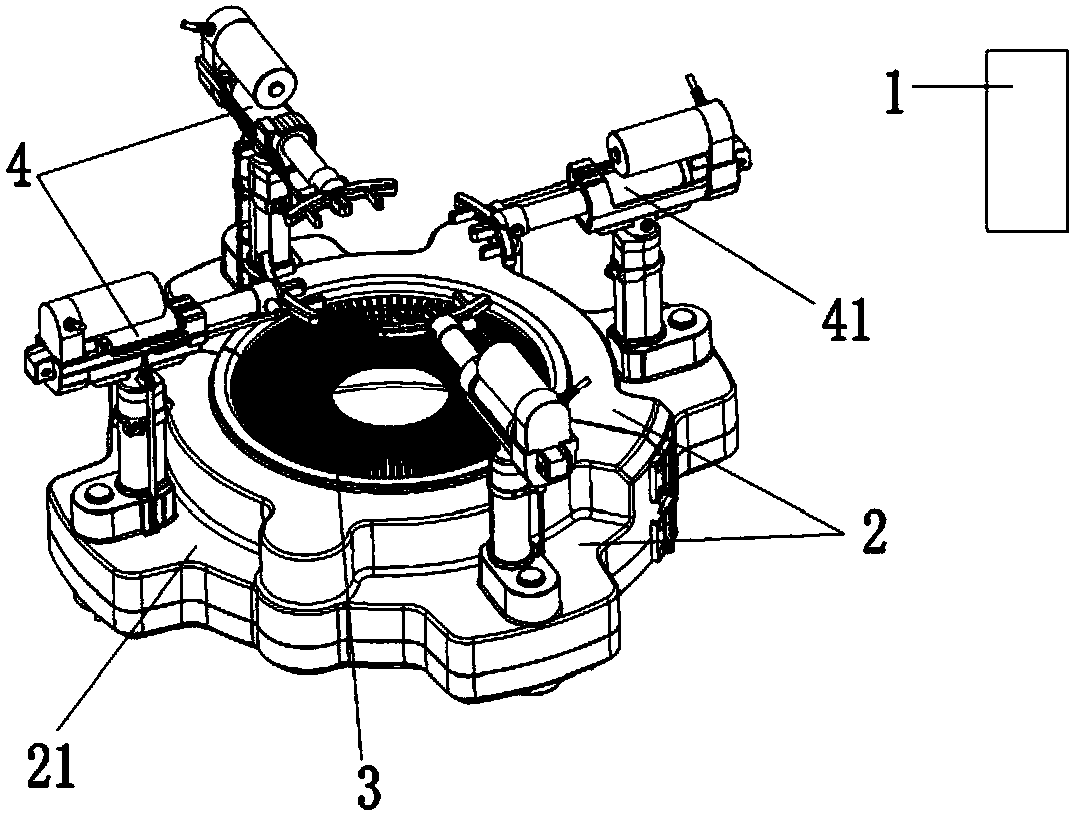

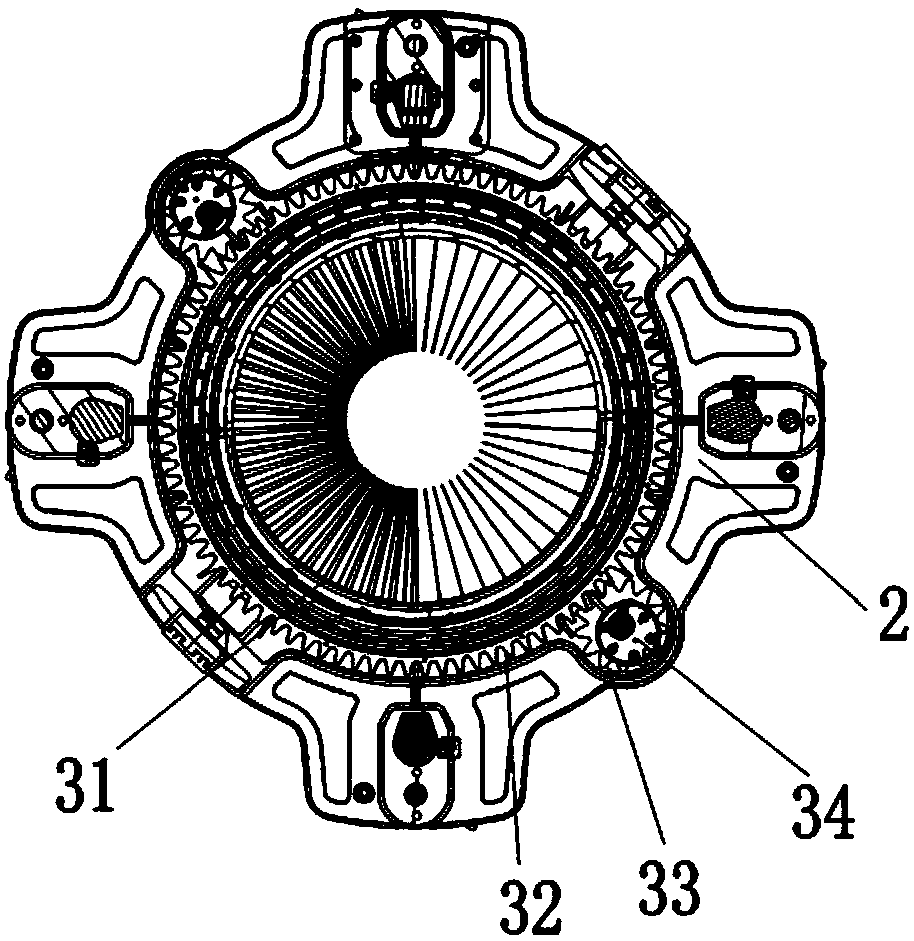

[0024] Such as Figure 1-3 As shown, the present invention provides a porcelain bottle cleaning robot, including a control device 1 and a main casing 2, wherein the main casing 2 is a hollow ring structure formed by docking two half-shells 21, and the two half-shells 21 One of the butt ends is hinged by a hinge, and the other is buckled by a connecting fastener 5, so that the two half shells 21 can be easily opened and placed on the porcelain bottle; the inner wall of the main shell 1 is provided with a cleaning mechanism 3, and the top surface of the main housing 1 is provided with a crawling mechanism 4 that can drive the main housing 1 up and down, and the cleaning mechanism 3 and the crawling mechanism 4 are both electrically connected to the control device 1 .

[0025] In the above scheme, when in use, first open the two half-shells 21 around the hinge and put them on the porcelain bottle for docking, then control the crawling mechanism 4 through the control device 1 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com