Full contact test circuit for TFT (Thin Film Transistor) array substrate

A technology of array substrate and test circuit, applied in the field of display panel detection, to achieve the effects of improving the success rate, preventing electrostatic discharge, and strong water and oxygen barrier ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

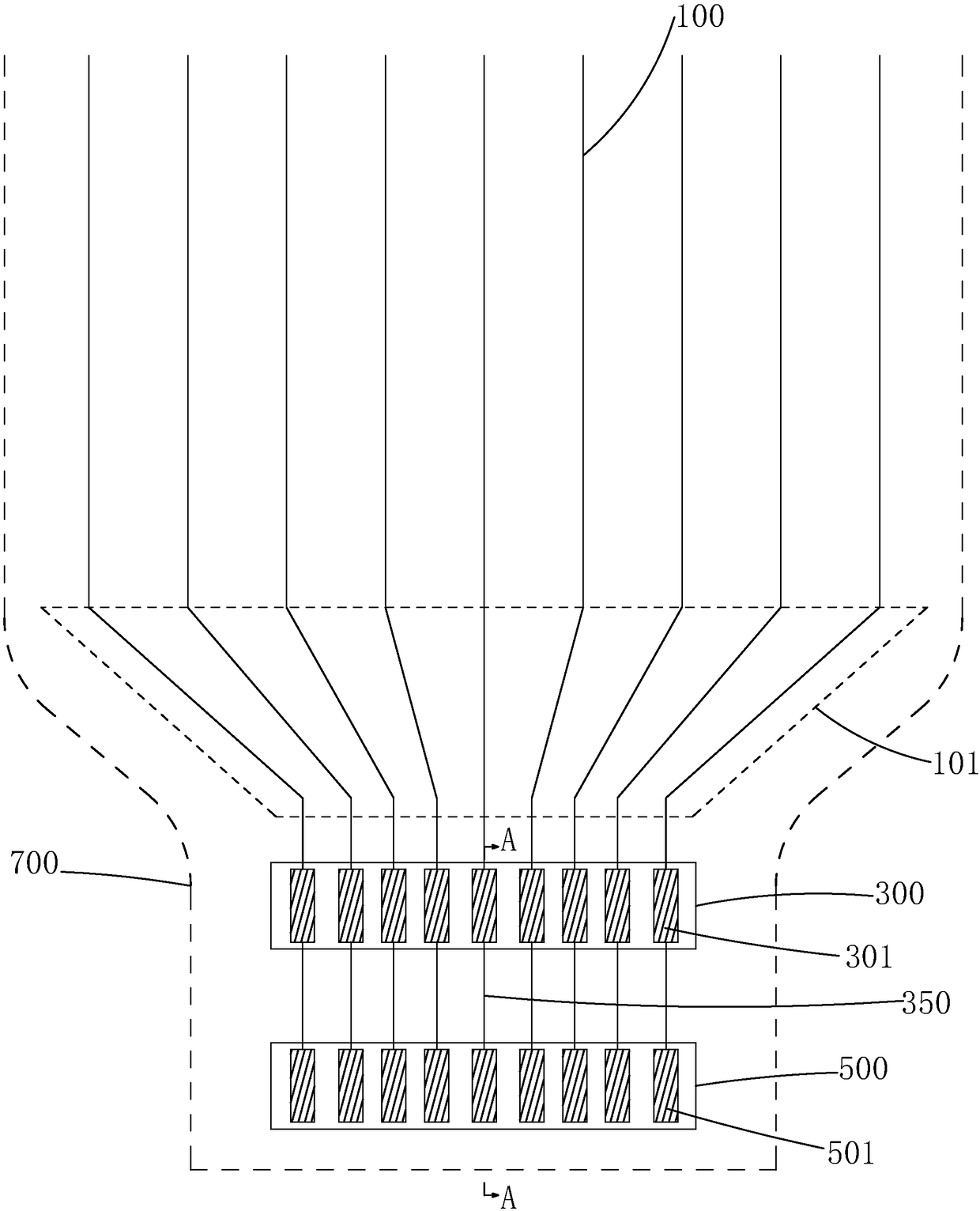

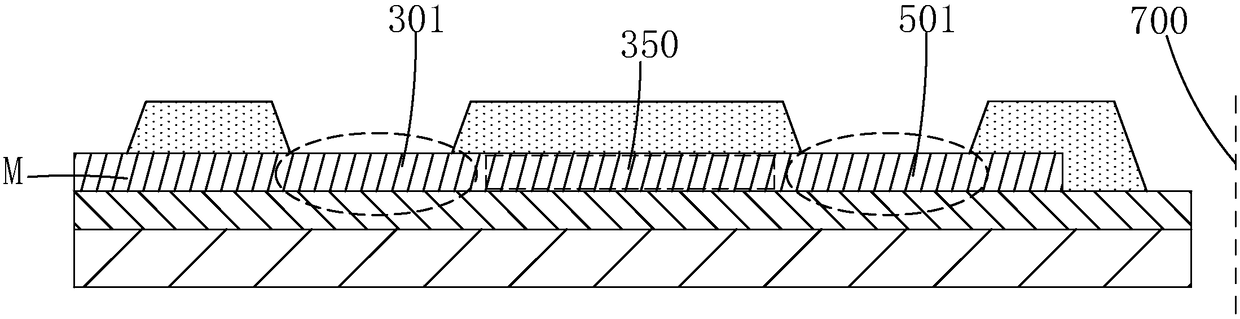

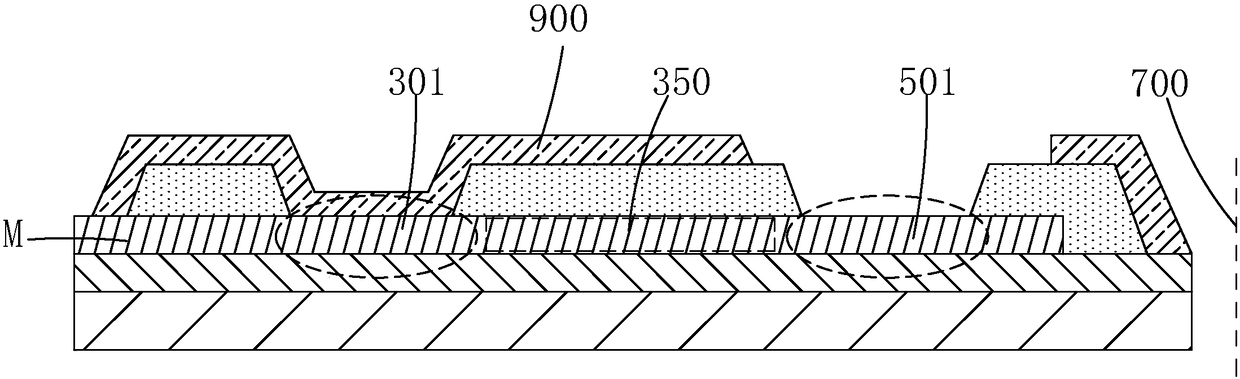

[0031] The invention provides a full-contact test circuit for a TFT array substrate. Please also see Figure 4 and Figure 5 The TFT array substrate full-contact test circuit of the present invention includes a plurality of data lines 1, a driver chip 3 arranged outside the fan-out area (Fanout) 11 of the plurality of data lines 1, and a driver chip 3 arranged in the driver chip 3. The test chip 5 on the side away from the fan-out area 11 . Different from the prior art where both the test chip and the driving chip are set within the panel cutting boundary, the TFT array substrate full-contact test circuit of the present invention sets the driving chip 3 within the panel cutting boundary 7, and the The test chip 5 is set outside the panel cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com