Glass fiber reinforced plastics bow and machining method thereof

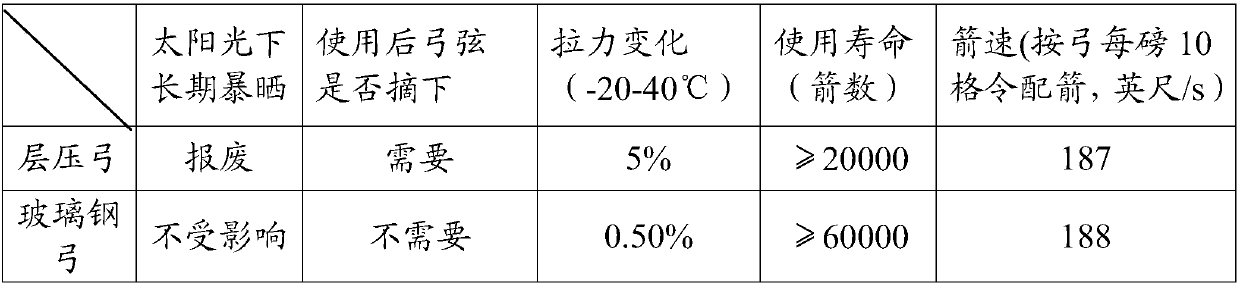

A processing method and glass fiber reinforced plastic technology, applied in bows/crossbows, weapons without explosives, offensive equipment, etc., can solve the problems of poor weather resistance and short service life of bows, improve weather resistance and service life, reduce average costs, and satisfy The effect of using demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

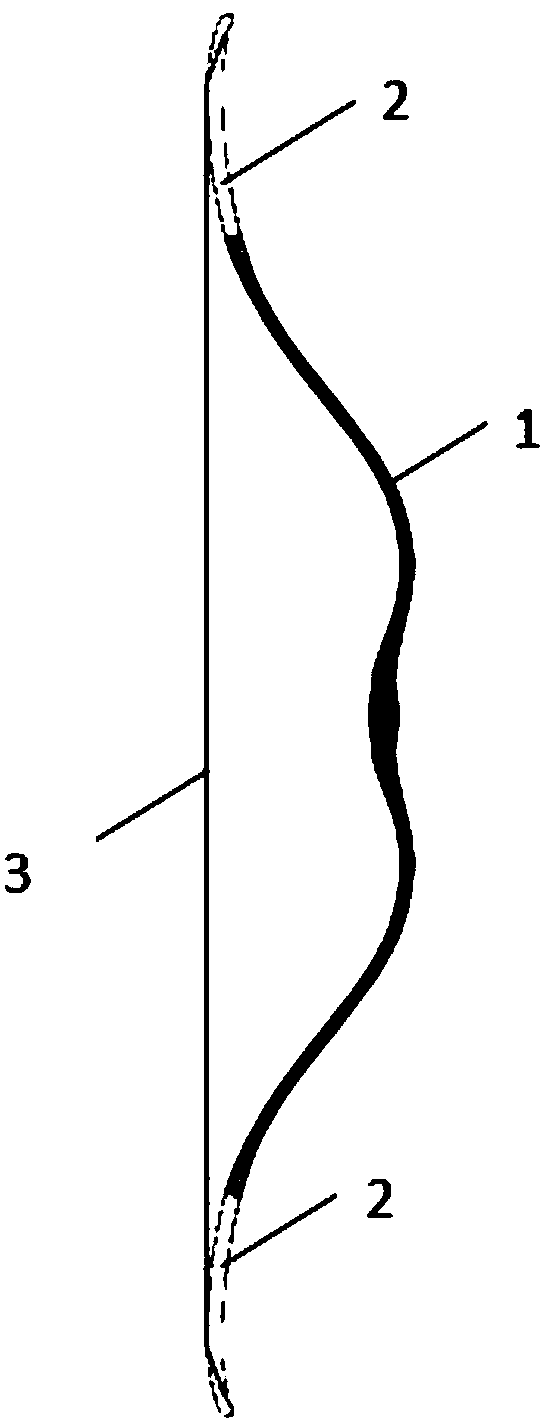

[0034] The invention provides a fiberglass bow, see attached figure 1 , including a bow arm 1, two bow tips 2 symmetrically arranged at both ends of the bow arm 1, a bow string 3 connecting the two bow tips 2, and a handle bonded to the bow arm 1; the bow arm 1 is made of glass fiber As, the bow tip 2 is made of wooden material.

[0035] Advantageously, the bow arm 1 is formed by pressing unidirectional fiberglass fibers; the bow tip 2 is bonded separately to the bow arm 1 .

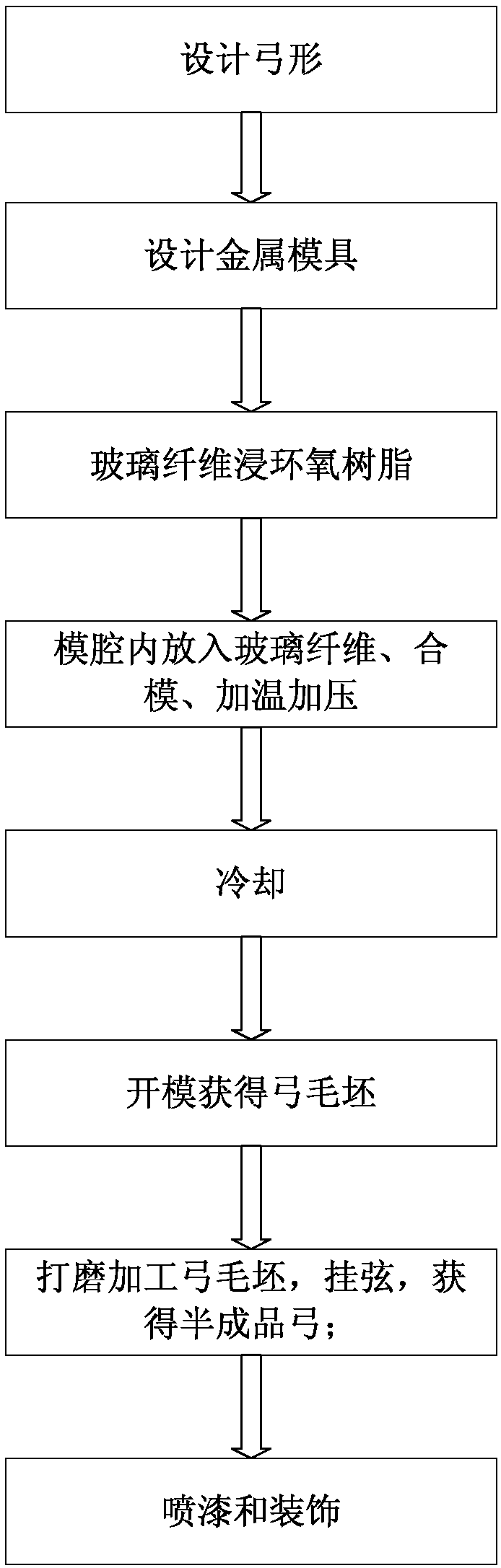

[0036] The present invention also provides a processing method of the FRP bow, comprising:

[0037] Step 1, designing the bow shape according to the mechanical properties of the bow;

[0038] Step 2, according to the arch in step 1, design the metal mold, and obtain the finished metal mold;

[0039] Step 3, glass fiber is immersed in resin glue, and the weight ratio of resin glue and glass fiber is 2:1;

[0040] Step 4, manually put the glass fiber immersed in the resin glue in step 3 into the mold c...

Embodiment 2

[0051] The invention provides a fiberglass bow, see attached figure 1 , comprising a bow arm 1, two bow tips 2 symmetrically arranged at both ends of the bow arm 1, a bowstring 3 connecting the two bow tips 2, and a handle bonded to the bow arm 1; the bow arm 1 and the bow tip 2 All are made of fiberglass.

[0052] Advantageously, the bow arm 1 and the bow tip 2 are integrally formed, both of which are formed by pressing glass fibers with unidirectional fiber directions.

[0053] The present invention also provides a processing method of FRP bow, see attached figure 2 ,include:

[0054] Step 1, designing the bow shape according to the mechanical properties of the bow;

[0055] Step 2, according to the arch in step 1, design the metal mold, and obtain the finished metal mold;

[0056] Step 3, the glass fiber is immersed in resin glue; the weight ratio of resin glue to glass fiber is 1.5:0.5;

[0057] Step 4, manually put the glass fiber immersed in the resin glue in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com