Bottom Compartment for Bottom Sealing of Underwater Sub-cabin of Large Cofferdam and Construction Method of Sub-cabin Bottom Cover

A construction method and bottom compartment technology, which are applied in infrastructure engineering, construction, etc., can solve problems such as inability to apply large-scale cofferdam, bottom compartment, subdivision, and bottom sealing, self-heavy cofferdam at the bottom section, and difficulty in lowering the cofferdam. Simple structure, good construction quality and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0038] An embodiment of the present invention provides a construction method for underwater subdivision and bottom sealing of a large cofferdam, including steps:

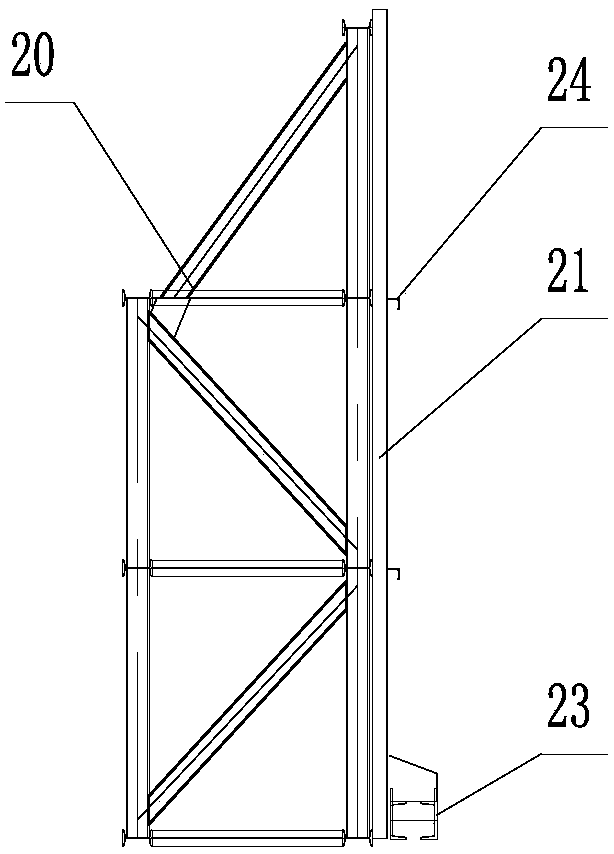

[0039] The bottom compartment 2 is prefabricated in blocks, the bottom compartment 2 is assembled from at least two compartment sections 2a, the compartment section 2a includes a truss 20, and at least one side of the truss 20 is provided with a panel 21;

[0040] After the cofferdam 1 is lowered into place, the two compartment sections 2a are lowered in sequence, the two compartment sections 2a are moved to the set position, and the two panels 21 are sealed and connected, so that all the panels 21 can form a sealed dividing surface, and The compartment section 2a is attached to the inner wall of the cofferdam 1, so that the bottom compartment 2 divides the cofferdam 1 into two inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com