Carbon dioxide hydrate reaction device and method for improving generation effect of carbon dioxide hydrate reaction device

A technology for hydrate formation and carbon dioxide, applied in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as complex formation process, achieve uniform particle size, improve formation effect, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

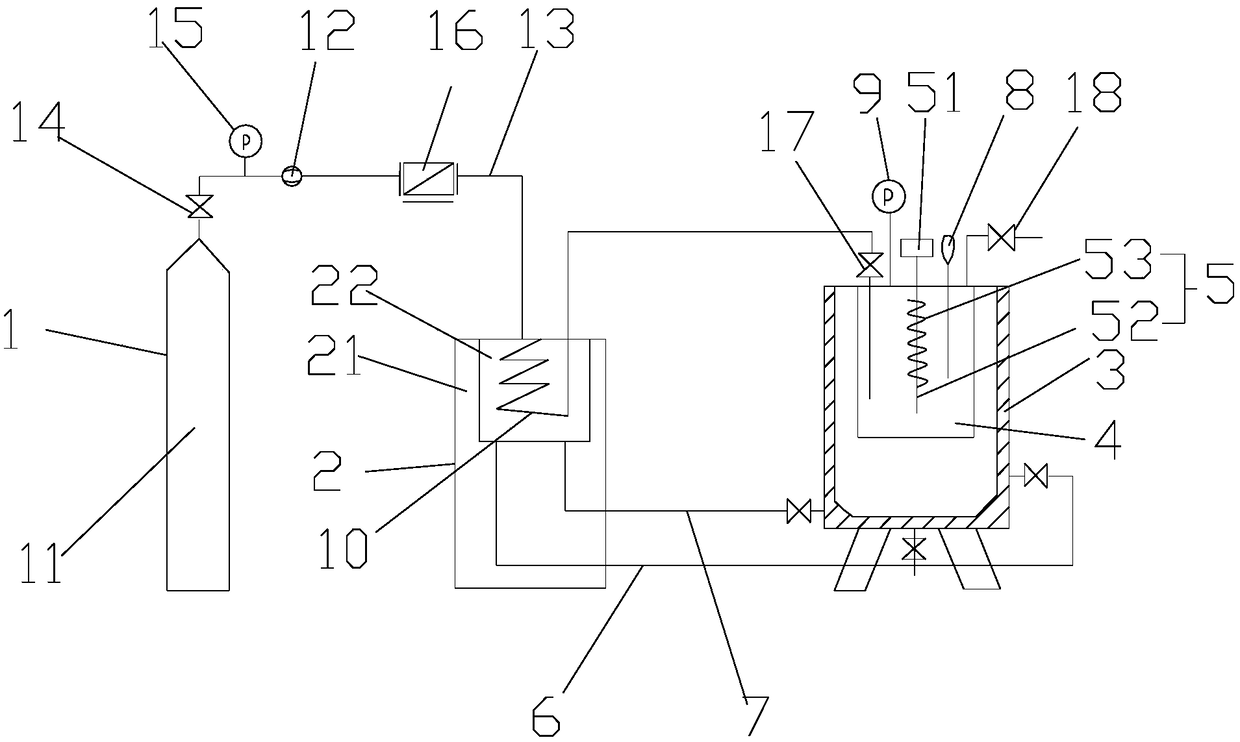

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0021] Such as figure 1 The carbon dioxide hydrate reaction device includes a gas supply system 1, a cooling system 2 and a high-pressure reactor 3, the gas supply system 1 is connected to one side of the cooling system 2, and the other side of the cooling system 2 is connected to the high-pressure reactor. The reaction kettle 3 is connected, and the gas supply system 1 includes a carbon dioxide gas supply tank 11, an air compressor 12, a first delivery pipeline 13 and a gas valve 14, and the first delivery pipeline 13 is provided with a pressure valve on the output side of the pressure valve. Table 15 and mass flow meter 16, the cooling system 2 includes a low-temperature water cooling tank 21 and a cooling tank 22, the cooling liquid is filled in the cooling tank 22, the high-pressure reactor 3 is provided with a reaction tank 4, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com