Special train for crane

A technology of cranes and jacking mechanisms, which is applied in the field of special cranes, which can solve the problems of beam slipping, casualties, tilting, etc., and achieve the effects of improving handling safety, ingenious structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

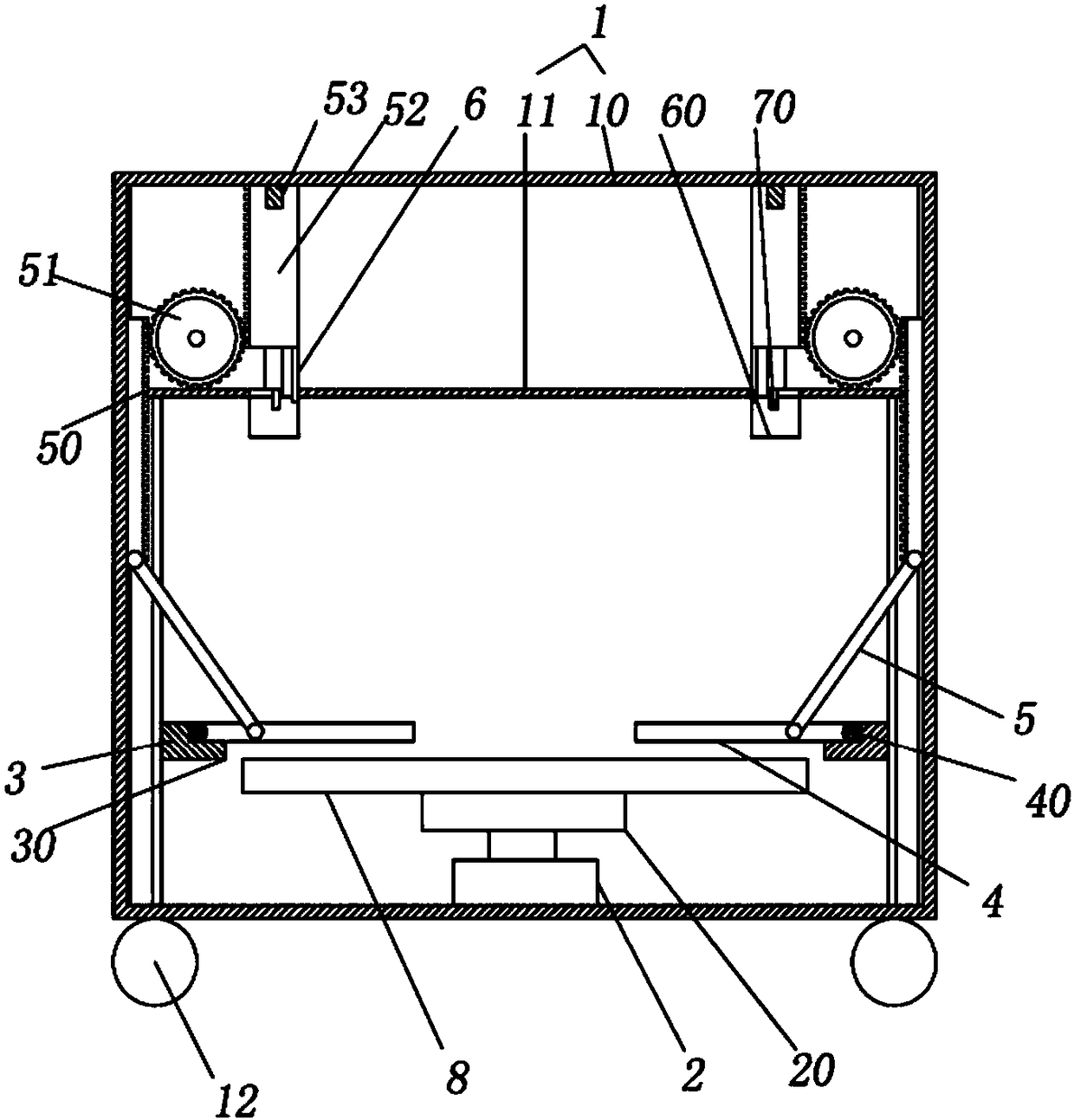

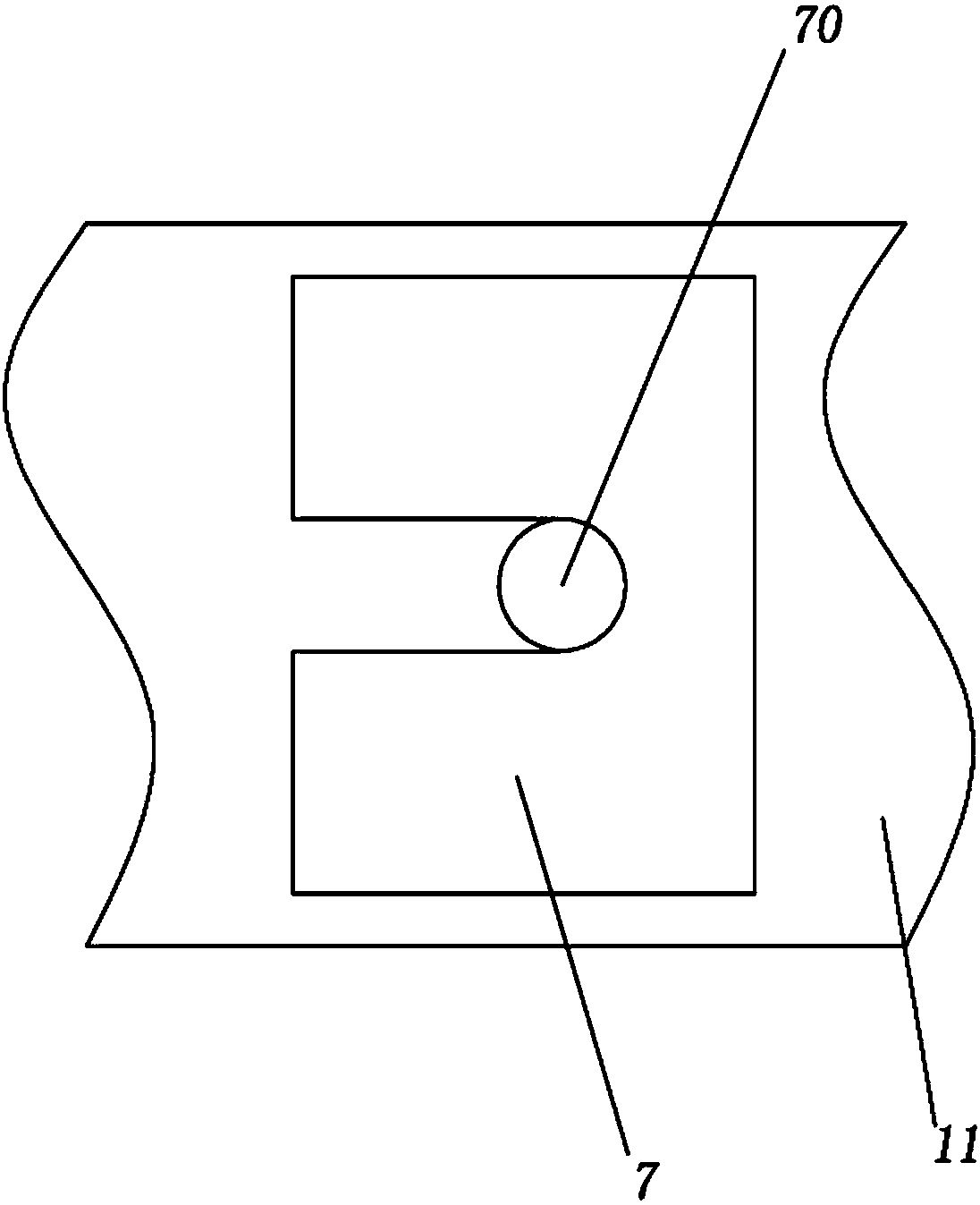

[0022] The reference signs in the drawings of the description include: mobile frame 1, square frame 10, middle plate 11, roller 12, hydraulic cylinder 2, support plate 20, support platform 3, limit part 30, groove 31, rotating plate 4, Bearing pin 40, connecting rod 5, driving rack 50, gear 51, driven rack 52, slide block 53, turning bar 6, support arm 60, U-shaped mouth 7, sucker 70, crossbeam 8.

[0023] The embodiment is basically as attached figure 1 Shown:

[0024] The special traveling crane for cranes includes a mobile frame 1, a jacking mechanism and two control mechanisms symmetrically arranged on both sides of the jacking mechanism.

[0025] The bottom of the mobile frame 1 is provided with rollers 12 to facilitate the transfer of the mobile frame 1; the mobile frame 1 includes a square frame 10 and an intermediate plate 11 welded in the square frame 10.

[0026] The jacking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com