Industrial Robot for Carrying Out Insulating Paper Inserting Operation on Motor Stator and Working Method Thereof

一种工作方法、插纸的技术,应用在敷设固体绝缘、机械手、制造工具等方向,能够解决绝缘纸推进深度差别很大、电动机生产成本高、影响电动机质量等问题,达到插纸效率高、减少劳动力的投入、一致性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

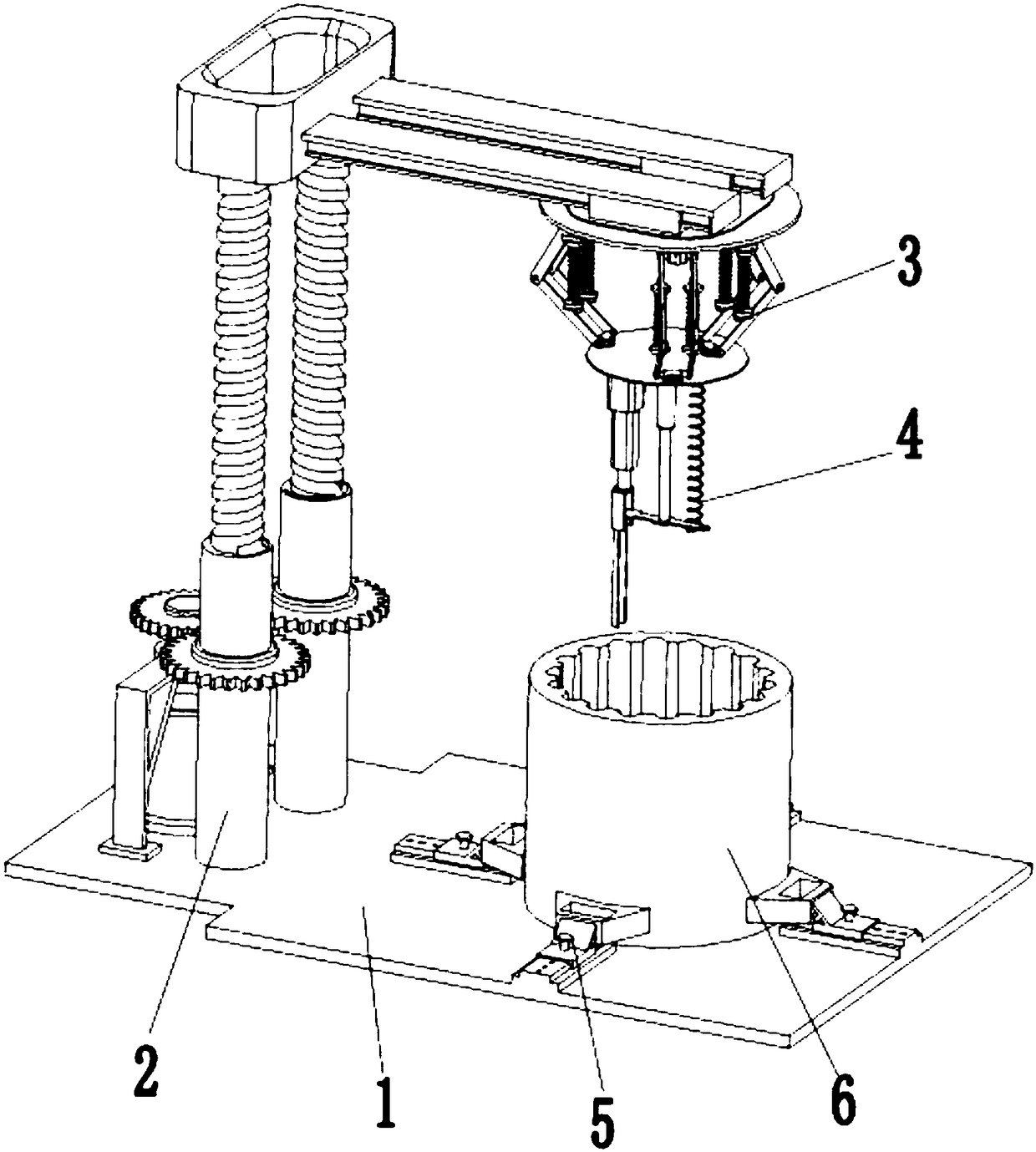

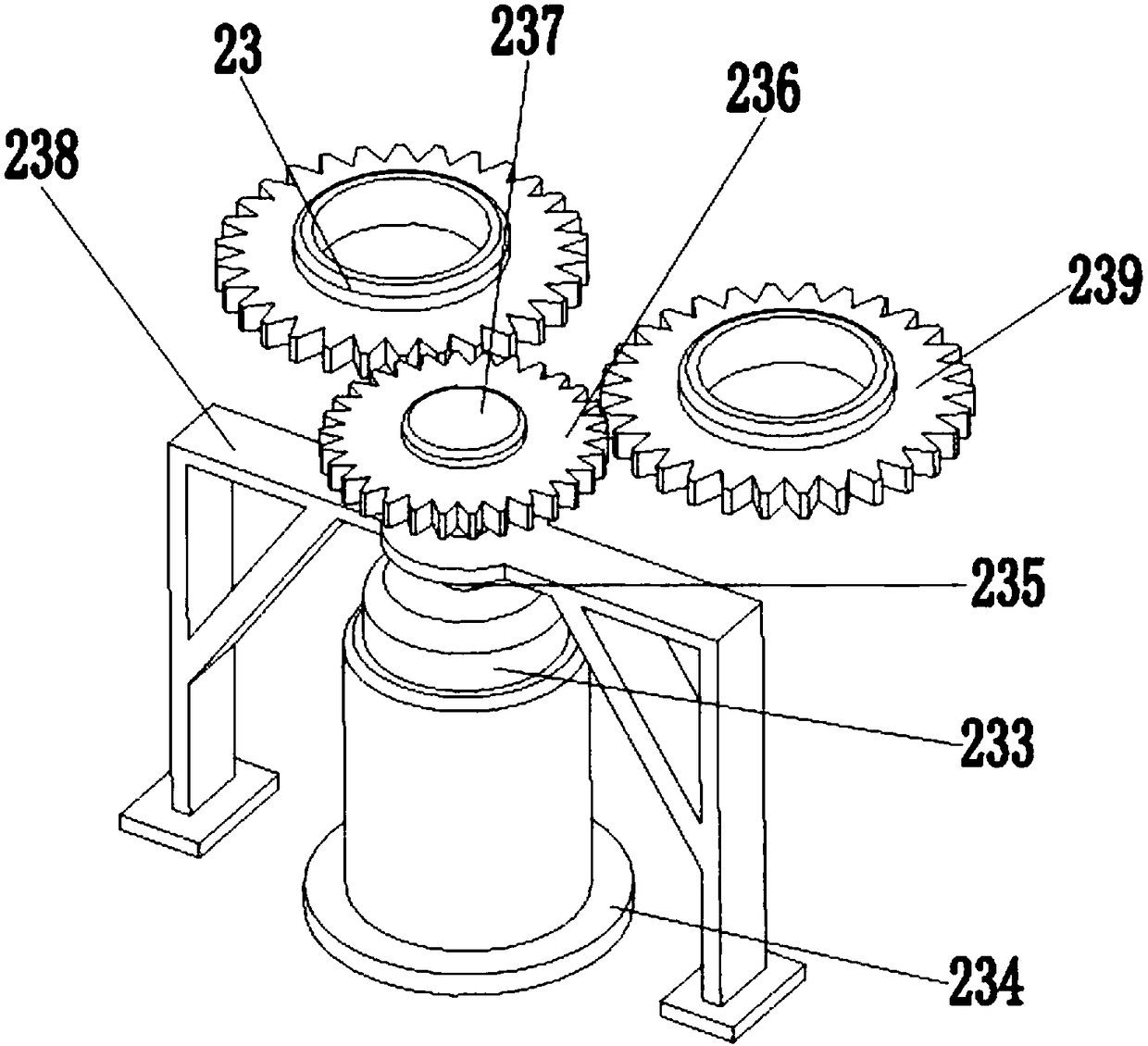

[0028] like Figure 1 to Figure 8 As shown, a six-degree-of-freedom paper insertion industrial robot based on a delta parallel mechanism includes a base 1, a support device 2, a delta parallel mechanism 3, a paper insertion device 4 and a fixing device 5; the base 1 is in the shape of a T-shaped plate Structure, the support device 2 is located at the rear end of the base 1, and the support device 2 and the base 1 are fixedly connected, the delta parallel mechanism 3 is installed at the front end of the support device 2, the paper insertion device 4 is located directly under the delta parallel mechanism 3, and the fixing device 5 The number is four, the fixing devices 5 are symmetrically arranged on the upper end surface of the base 1 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com