Double-shaft feeding grinding wheel deflection type glass chamfering mechanism

A technology of feeding mechanism and chamfering mechanism, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, grinding machines, etc. and other problems to achieve the effect of eliminating the difference in instantaneous speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

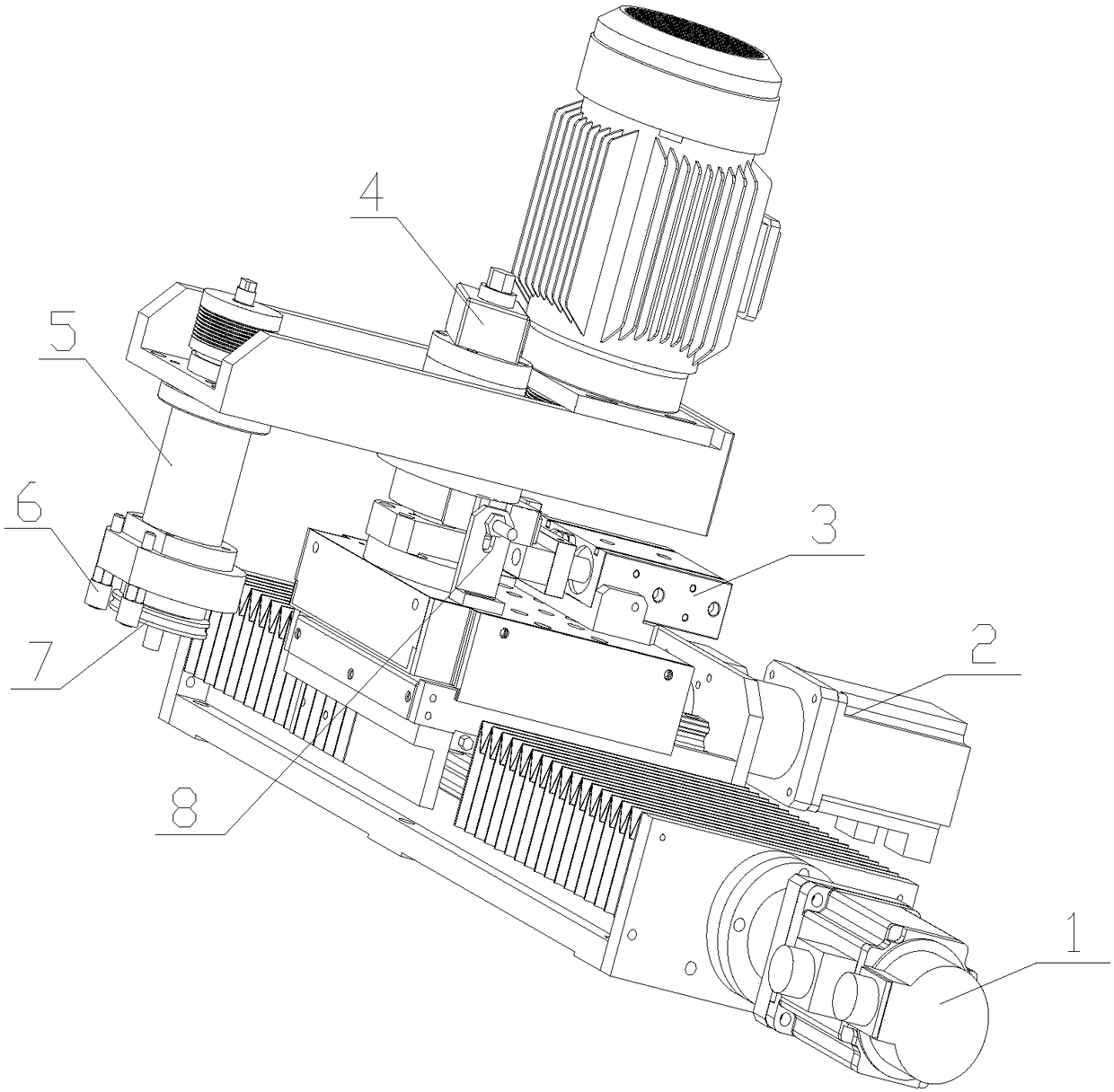

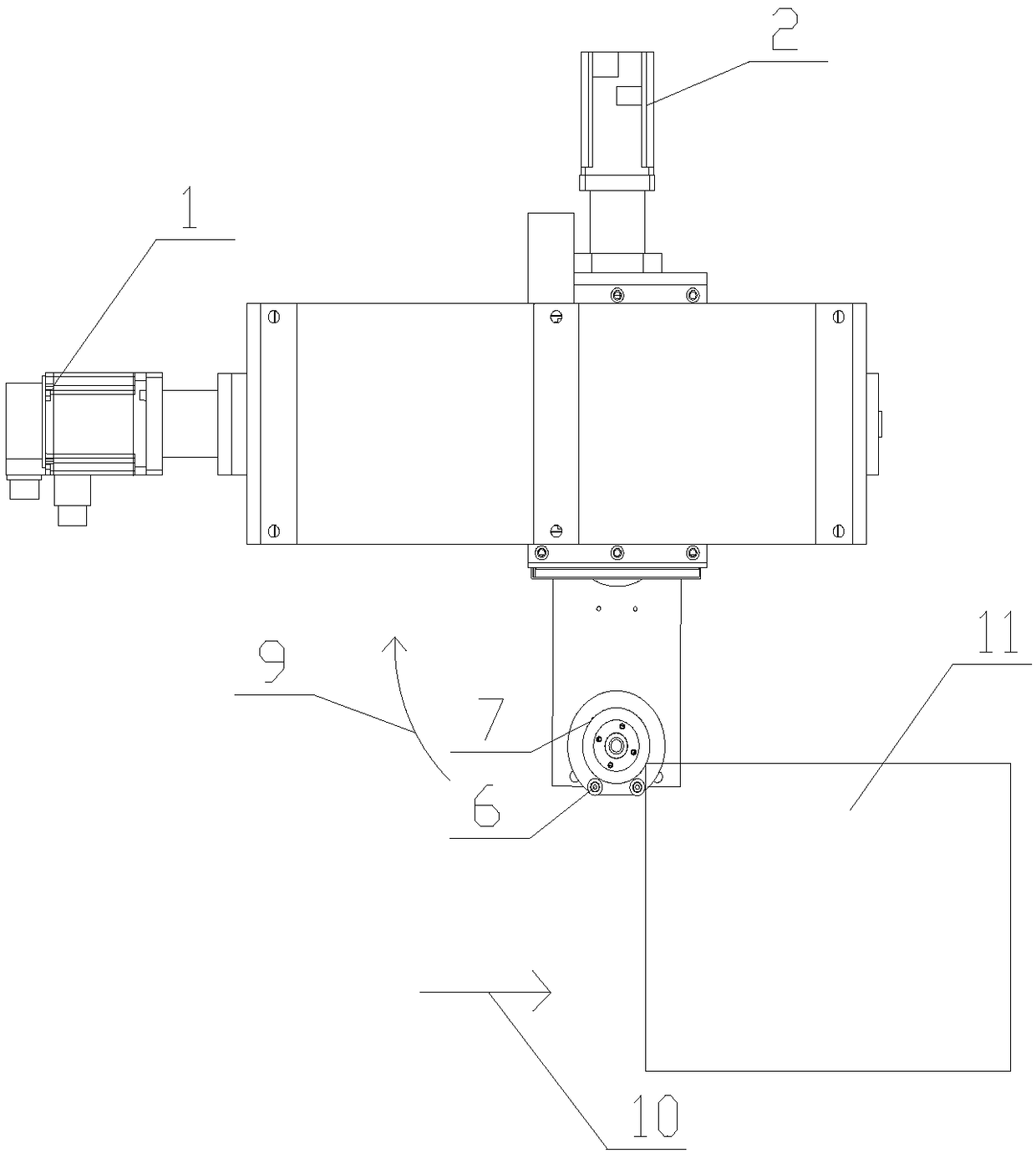

[0025] Such as figure 1 , 2 . As shown in 3, a dual-axis feed grinding wheel can be deflected glass chamfering mechanism, including X-axis feed mechanism 1, Y-axis feed mechanism 2, power head yaw mechanism 3, power head rotary connection shaft 4, Grinding wheel power head mechanism 5, nylon ball 6, grinding wheel 7 and PLC, the X-axis feed mechanism 1 is connected to the Y-axis feed mechanism 2 and controlled by PLC, and the Y-axis feed mechanism 2 is connected to the power head in rotation The shaft 4 is connected, the grinding wheel power head mechanism 5 is connected with the power head rotation connection shaft 4 and the grinding wheel power head mechanism 5 can rotate around the power head rotation connection shaft 4, and the X-axis feed mechanism 1 and the Y-axis feed The direction in which the mechanism 2 drives the grinding wheel power head mechanism 5 is perpendicular to each other. The power head yaw mechanism 3 is connected with the Y-axis feed mechanism 2 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com