Improved agricultural feed smashing device

A technology of pulverizing device and feeding device, applied in feed, application, use of liquid separating agent, etc., can solve the problems of incomplete pulverization of materials, reduced product quality, long processing time, etc., so as to avoid the reduction of equipment life and ensure stable work. The effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

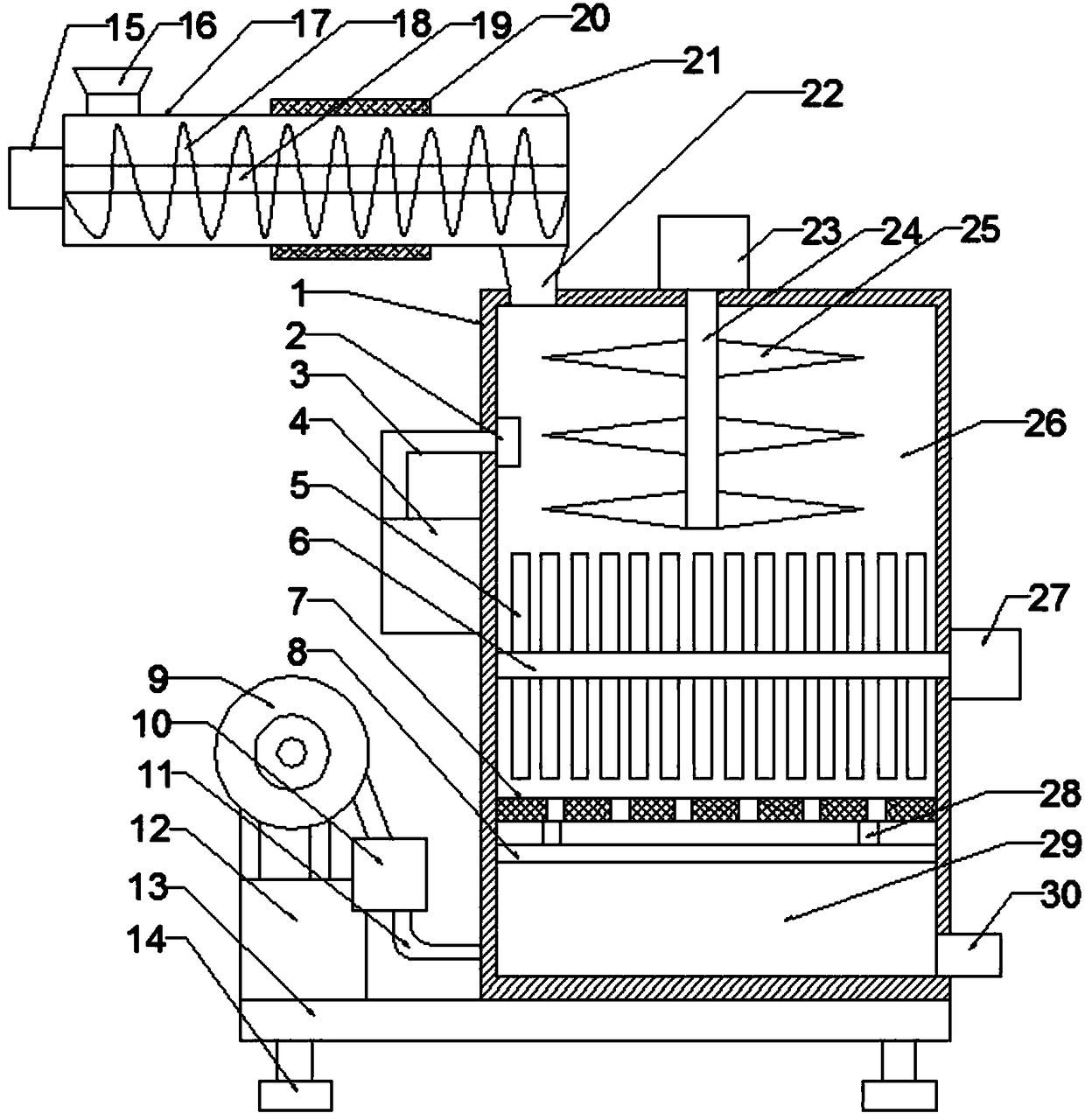

[0016] see Figure 1-3 , an improved agricultural feed crushing device, comprising a feeding device, a feed crushing device and a feed sterilizing device; , auger shaft 19, heating cavity 20, exhaust duct 21 and lower hopper 22; the auger cylinder 17 is arranged on the left side above the casing 1, and the auger cylinder 17 communicates through the lower hopper 22; the feed hopper 16 It is arranged on the left side above the auger barrel 17; the auger shaft 19 is horizontally arranged inside the auger barrel 17, and the auger shaft 19 outer wall is provided with auger blades 18; the motor 15 is arranged in the auger barrel close to the feeding One end of the bucket 16 is connected to the motor 15 and the auger shaft 19; the heating chamber 20 is arranged in the middle of the outer side of the auger barrel 17, and the heating chamber 20 can heat an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com